Feeder roller

A feeder and roller technology, applied in the direction of conveyors, mechanical conveyors, shafts and bearings, etc., can solve the problems of large particle size of broken materials, frequent maintenance, poor lubrication, etc., to prolong service life, improve mechanical performance, reduce The effect of maintenance frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

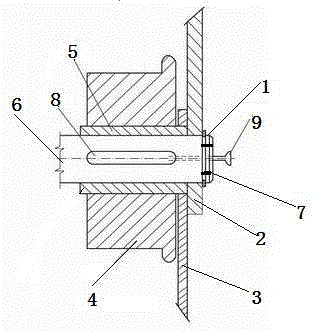

[0019] Such as figure 1 As shown, a feeder roller in this embodiment includes a clamping plate 1, an outer chain plate 2, an inner chain plate 3, a roller 4, a steel sleeve 5, a pin shaft 6, and a fastening screw 7; The fixed screw 7 is fixed on the end of the pin shaft 6; the outer chain plate 2 and the inner chain plate 3 are arranged parallel to each other; the inner chain plate 3 is stuck between the roller 4 and the steel sleeve 5. An oil groove 8 is also provided on the steel sleeve 5 . An oil cup 9 is also provided at the end of the pin shaft 6 . The material of roller 4 and steel sleeve 5 is cast steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com