Full-automatic quenching line of automobile clutch diaphragm spring

A diaphragm spring and clutch technology, applied in the field of automatic quenching line for automobile clutch diaphragm spring, can solve the problems of insecure product quality, high working environment temperature, poor positioning accuracy, etc. The effect of high motion accuracy and low inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

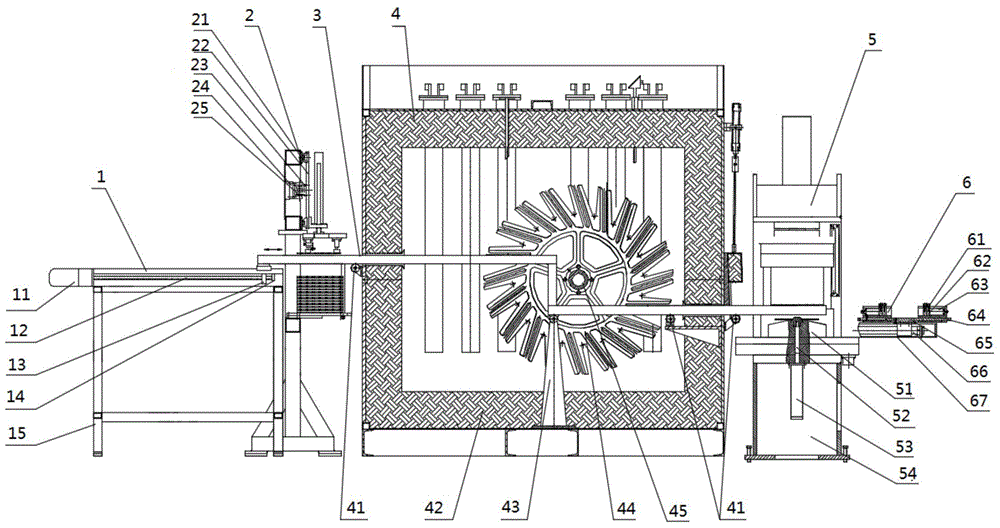

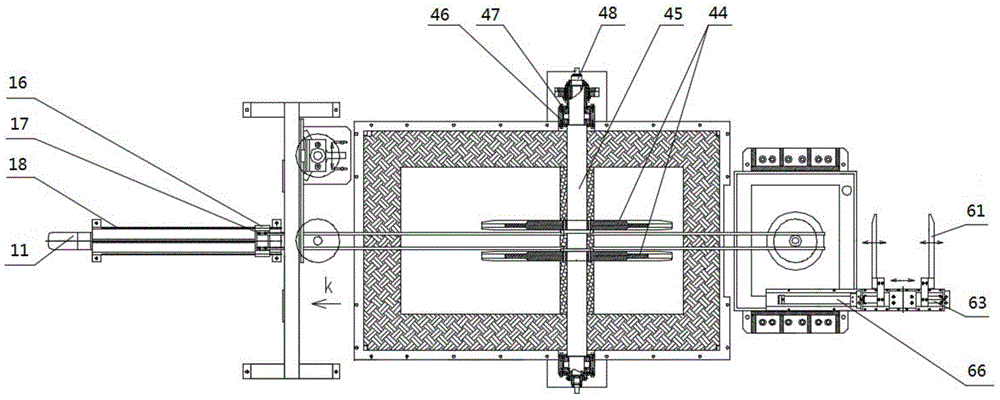

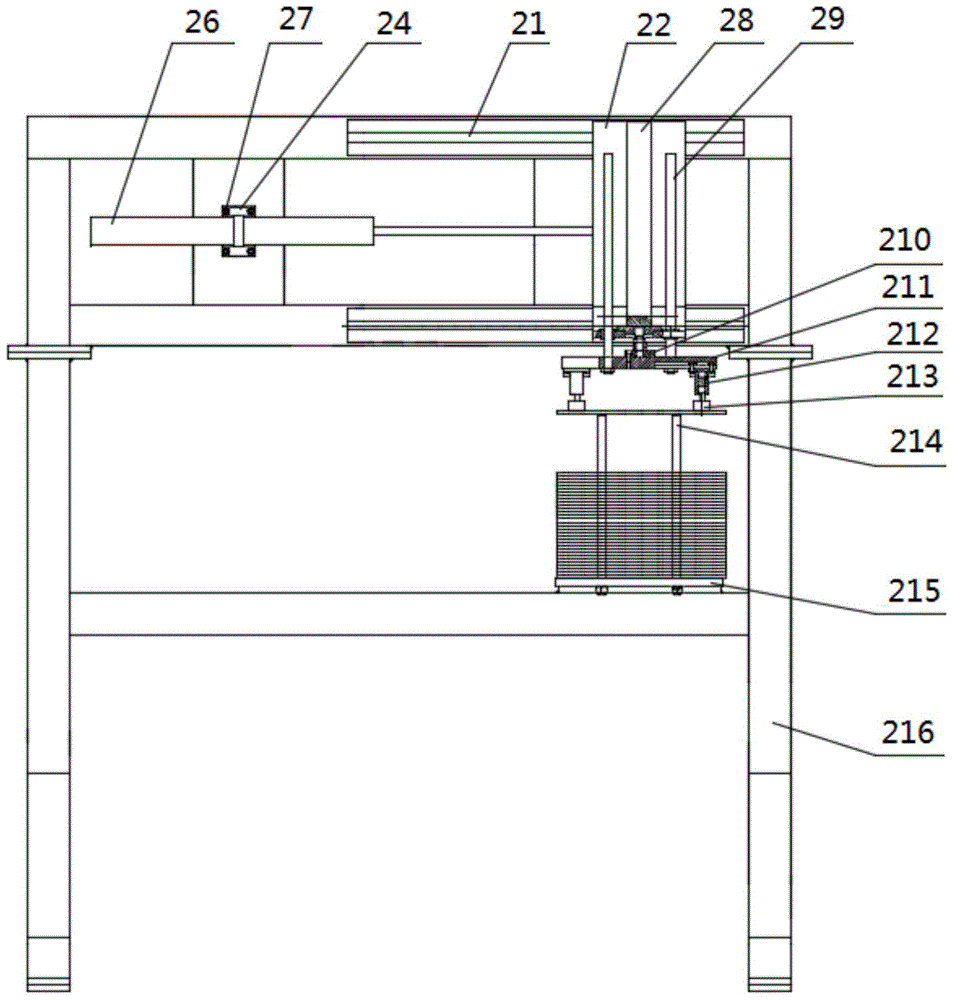

[0043] Such as Figure 1-Figure 3 As shown, the present invention provides a kind of automobile clutch diaphragm spring full-automatic quenching line, comprises pusher mechanism 1, sucker feeding mechanism 2, feeding rod 3, heating furnace 4, quenching press 5 and unloading mechanism 6; The feeding rod 3 runs through the heating furnace 4, one end is in contact with the pushing mechanism 1, and the other end is in contact with the discharge structure 6; the suction feeding mechanism 2 is located between the pushing mechanism 1 and the heating furnace 4; The quenching press 5 is located between the heating furnace 4 and the unloading mechanism 6;

[0044] The pushing mechanism 1 includes a reducer 11, a lead screw 12, a nut 13, a screw support frame 14, a pushing bracket 15, a nut connecting plate A16, a bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com