A vertical axis wind turbine

A wind power generator, vertical axis technology, applied to wind power generators, wind power motor combinations, wind power generators at right angles to the wind direction, etc., can solve the problems of weakening the wind-catching ability of the blades and limiting the installed capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

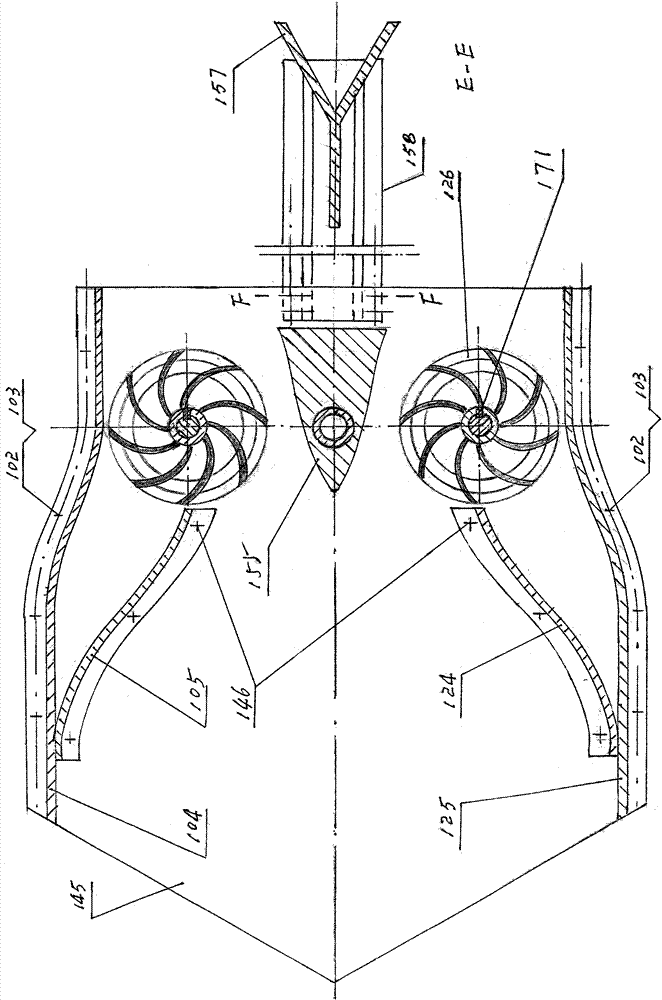

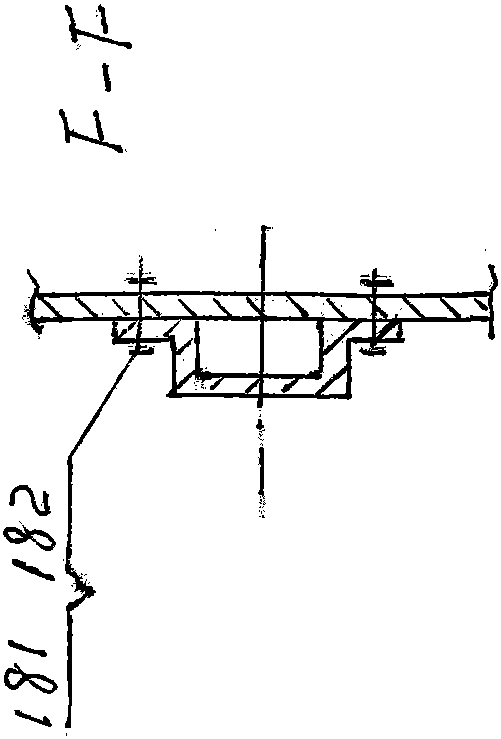

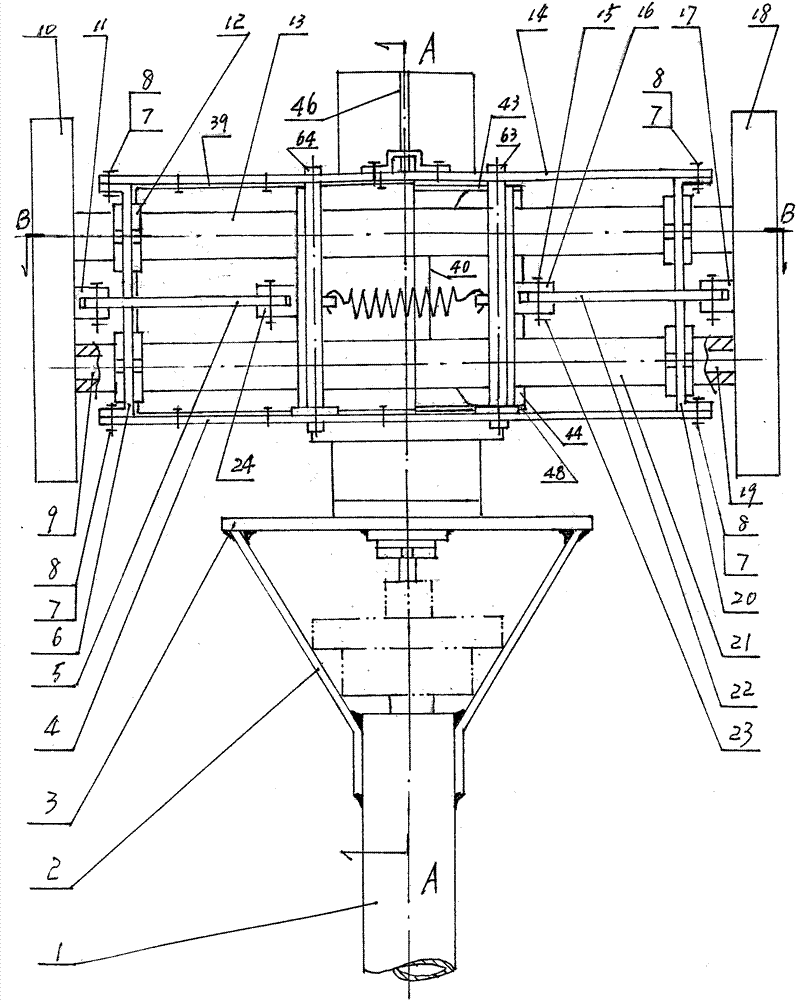

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown: at the upper end of a vertical tower pole 1 with a certain height and sufficient strength, a horizontal circular countertop 3 with sufficient rigidity is firmly supported by four support poles 2. A vertical cylindrical sleeve 34 is fixedly welded to the center of the countertop 3 through its circular hole; on the outside of the sleeve 34, a cylindrical bracket 36 is supported by a thrust centripetal sliding bearing 35; The outer side of the upper end of the bracket 36 is horizontally fixedly welded to a lower panel 4 of the deflector wind collecting hood. The lower panel 4 should have a certain rigidity, and its horizontal shape is like a javelin head, and the bracket 36 should It is combined on the symmetrical center plane of the lower panel 4—(hereby define the tip of the javelin head as the front of the deflector wind collecting hood). At the upper end of the sleeve 34, the axial movement of the bracket 36 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com