Low-noise cutting ball valve

A cut-off ball valve, low-noise technology, applied to the cock, valve details, valve device and other directions including the cut-off device, can solve the health hazards of operators, large valve pressure difference, wear of valve body and ball, etc., to improve work environment, increasing friction loss, and eliminating cavitation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

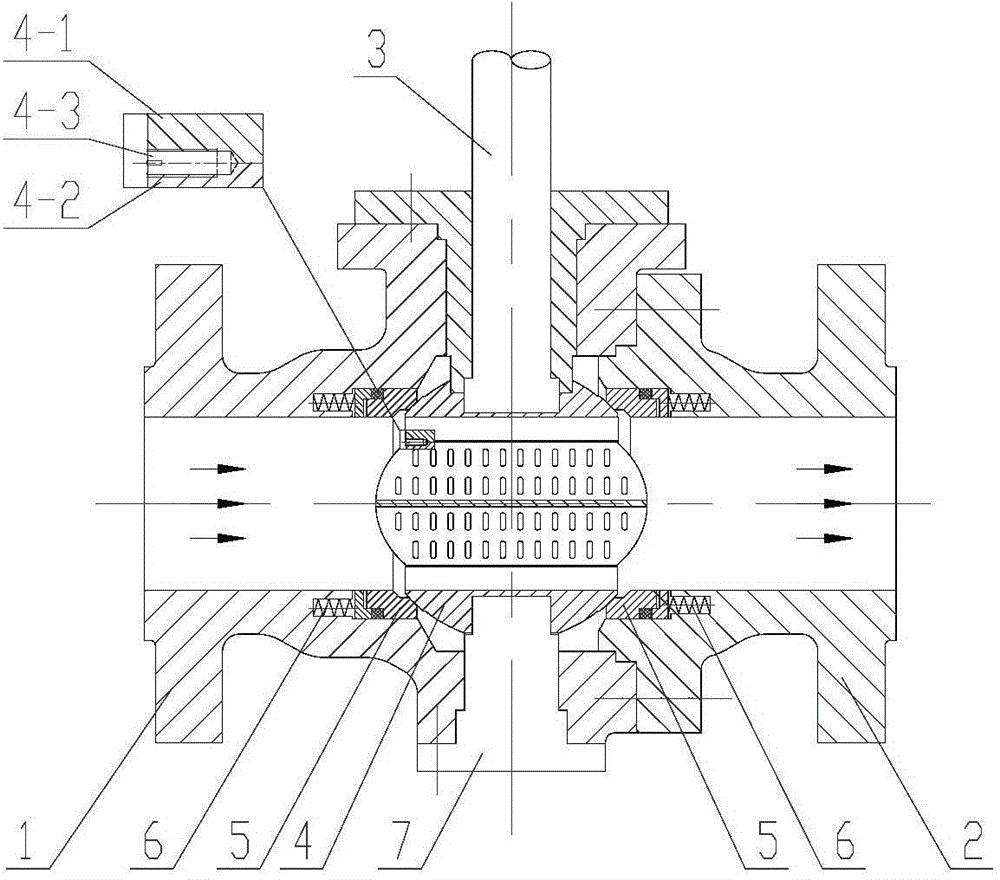

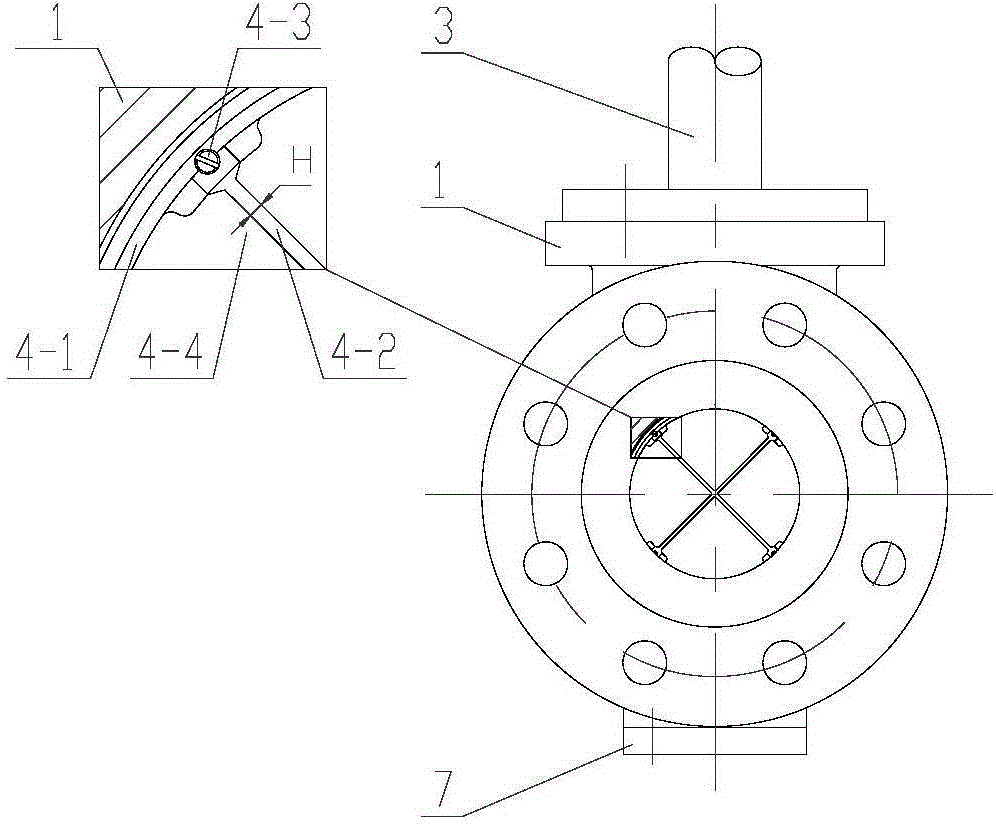

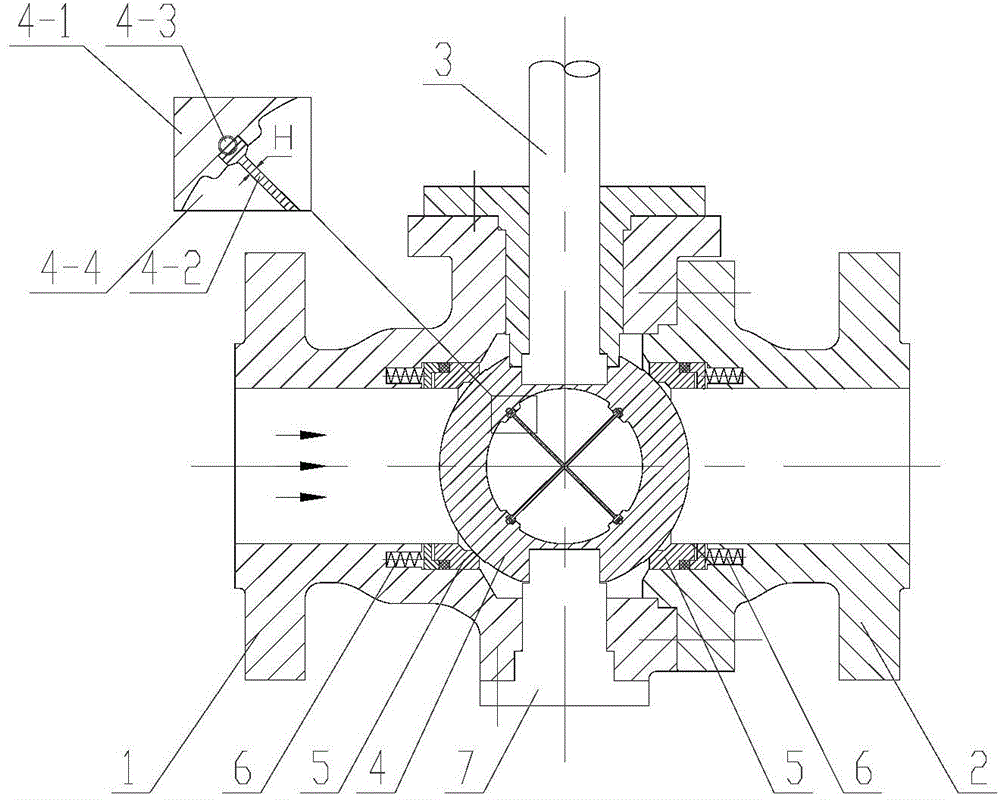

[0028] Attached below Figure 1~4 The invention is described in further detail.

[0029] Such as Figure 1~4 As shown, the present invention proposes a low-noise cut-off ball valve, the structure of which includes a valve body composed of a first valve body part 1 and a second valve body part 2. In the valve body, a fixed shaft 7 supports a ball structure 4, and the ball body The structure 4 forms a spherical seal with the two valve seats 5, and the spring force provided by the spring 6 presses the valve seat 5 to the ball structure 4 to realize the sealing between the ball 4-1 and the valve seat 5, and the valve stem 3 drives the ball structure 4 to rotate to complete the switching action . By adopting the new spherical structure 4, the flow channel grille 4-2 is arranged in the spherical flow channel 4-4, so that when the cut-off ball valve is fully open, the resistance to the fluid is small, and the normal circulation of the fluid will not be affected. During the working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com