Glass syringe seal sampling auxiliary joint device used for insulating oil gas chromatography

A technology for auxiliary joints and chromatographic analysis, applied in the field of glass syringe sealing and sampling auxiliary joints, to achieve the effects of smooth gas transfer, improved test measurement accuracy, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

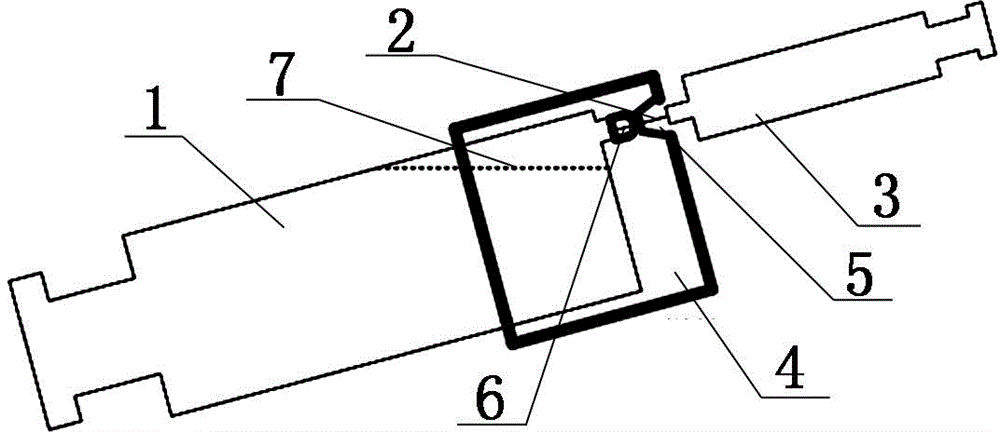

[0013] Example: Insert the 100ml A glass syringe 1 into the sampling auxiliary joint 4, turn the A glass syringe 1, make the rubber sealing cap 6 of the syringe head and the auxiliary joint 4 fasten, so that the funnel-shaped needle guide 5 and the rubber sealing cap 6, and the A glass syringe head on the same vertical line. Then use the double-ended needle 2 and insert it from the guide 5 to transfer the sample detection gas (balance gas) in the A glass syringe 1 to the 5ml B glass syringe for chromatographic analysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com