Anticorrosive coating high-temperature and high-pressure resistant performance evaluation testing device and testing method

A technology of anti-corrosion coating and evaluation test, applied in measuring device, using stable tension/pressure to test material strength, weather resistance/light resistance/corrosion resistance, etc. High-pressure performance testing and other issues, to achieve the effect of accurate and efficient anti-corrosion coating high temperature and high pressure resistance, accurate and efficient evaluation, and enhanced sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

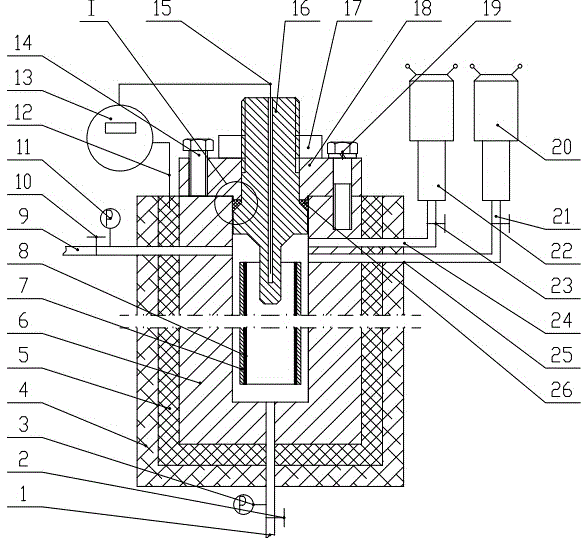

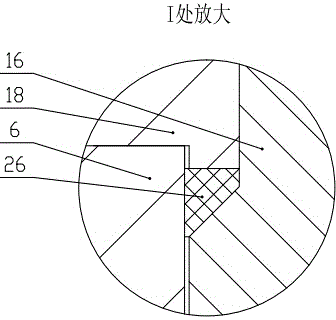

[0027] According to attached figure 1 and 2 It can be seen that the present invention specifically relates to an anti-corrosion coating high-temperature and high-pressure performance evaluation test device and test method, which are used to simulate the high-temperature and high-pressure environment encountered by the anti-corrosion coating in the process of oil and gas exploitation. The test device is mainly composed of heating system, temperature control system, pressurization system, pressure measurement system, high pressure valve and pipeline, including liquid discharge port 1, liquid discharge valve 2, first pressure gauge 3, insulation cover 4, heating barrel 5 , test barrel 6, sample 7, anti-corrosion coating 8, air release port 9, air release valve 10, second pressure gauge 11, power cord 12, temperature controller 13, top wire 14, temperature measuring thermocouple 15, expansion tightness Cover 16, expansion lock nut 17, gland 18, bolt 19, liquid pressure pump 20, l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com