Adaptive fault detection method for airplane rotation actuator driving device based on deep learning

A technology of rotary actuators and driving devices, which is applied in the direction of instruments, electrical testing/monitoring, testing/monitoring control systems, etc., to achieve the effect of increasing the number of layers, improving accuracy, and improving generalization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

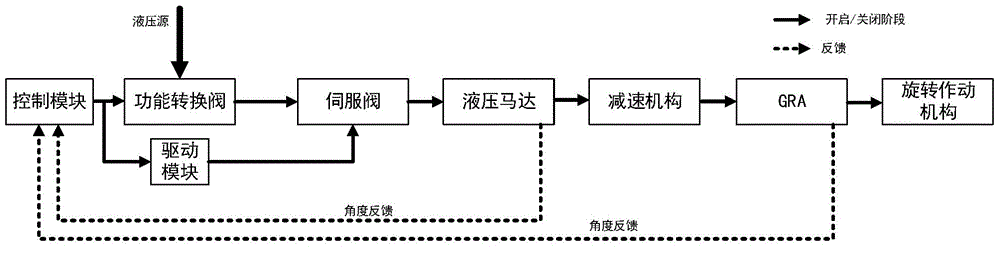

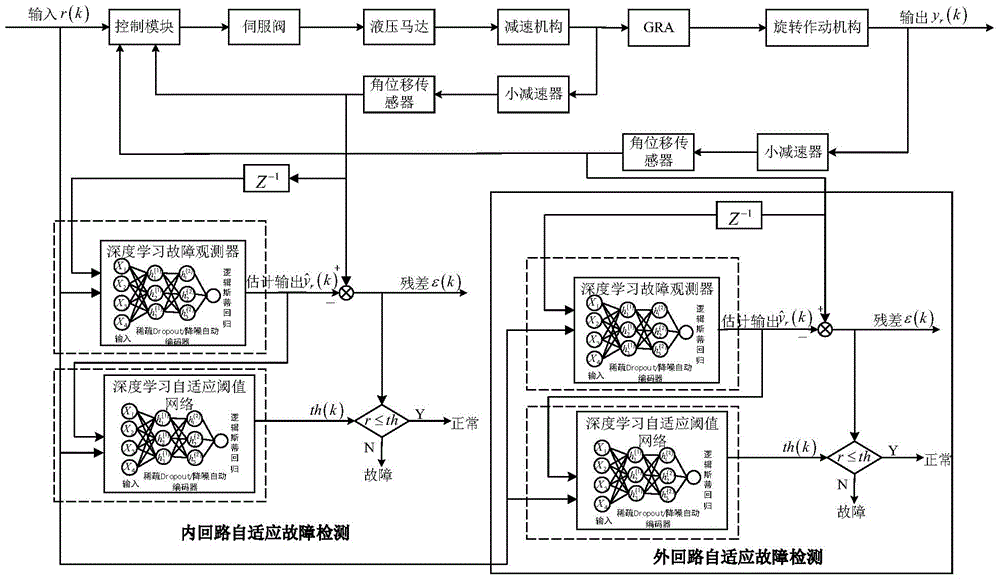

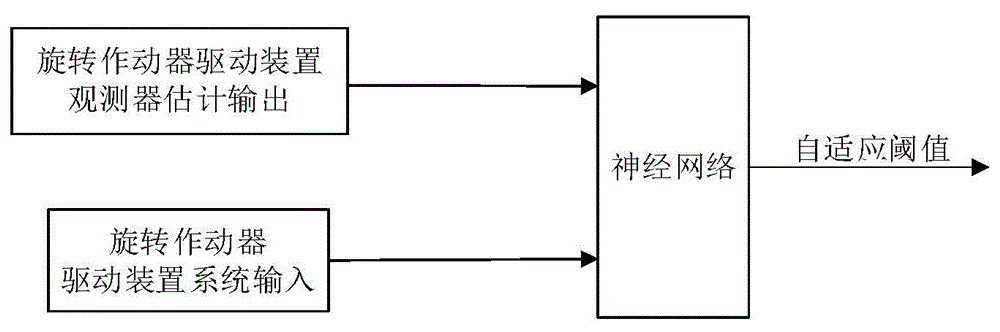

[0050] The invention discloses an adaptive fault detection method for an aircraft rotary actuator drive device based on deep learning. The method is based on deep learning of a sparse Dropout autoencoder, a stacked denoising autoencoder (Stacked Denoising Autoencoder) and Logistic regression. Adaptive fault detection for aircraft rotary actuator drives. On the basis of the fault analysis of the aircraft rotary actuator drive device, and aiming at the problems of the current classification algorithm with limited robustness and precision, this method draws on the relevant field knowledge of image pattern recognition, and adopts deep learning based on multi-layer neural network for self-identification. The known method realizes the self-expression of the original data under the condition of input partial occlusion by using the sparse Dropout autoencoder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com