Three-dimensional printing elastic fabric with flame-retardant fabric layer

A flame-retardant fabric and three-dimensional printing technology, which is applied in the field of textile fabrics and fabrics, can solve the problems of fabric elasticity, lack of three-dimensional effect, and discomfort, etc., and achieve the effect of easy elasticity, enhanced three-dimensional effect, and good drape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

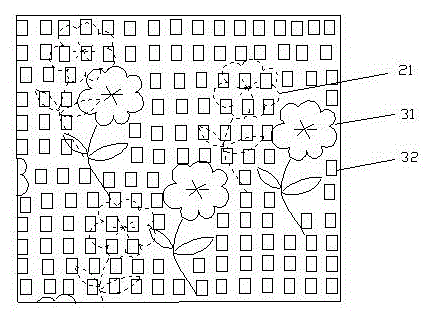

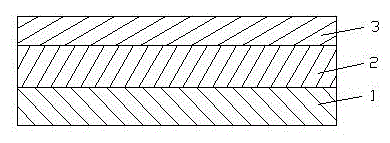

[0011] see figure 1 and figure 2 , The present invention relates to a three-dimensional printed elastic fabric with a flame-retardant fabric layer, comprising a base fabric 1, the upper surface of the base fabric 1 is a printing layer 2, and the upper surface of the printing layer 2 is a fluff layer 3. The printing layer 2 includes colorful printing flowers 21; the fluff layer 3 includes fluff flowers 31 and fluff blocks 32, and the fluff flowers 31 and fluff blocks 32 are of the same color. The downy flowers 31 are in the same style as the printed flowers 21 , and the downy flowers 31 cover part of the printed flowers 21 . The fluff pieces 32 are uniform in size and evenly distributed around the fluff flowers 31 .

[0012] The base fabric 1 is made of fabric, the fabric is a warp knitted fabric, the laying yarn rule is 1-0 / 2-3, the veil is made of 75D / 36 T400 polyester fiber fully drawn filament, and the bottom yarn is made of FDY 84D / 36F polyester filament, the T400 poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com