Automatic screw disassembling method and device based on visual positioning and torque control

A technology of torque control and visual positioning, applied in manufacturing tools, metal processing equipment, metal processing, etc., can solve problems such as low efficiency, operator injury accidents, rising labor costs, etc., to achieve easy operation, accurate positioning, and disassembly efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

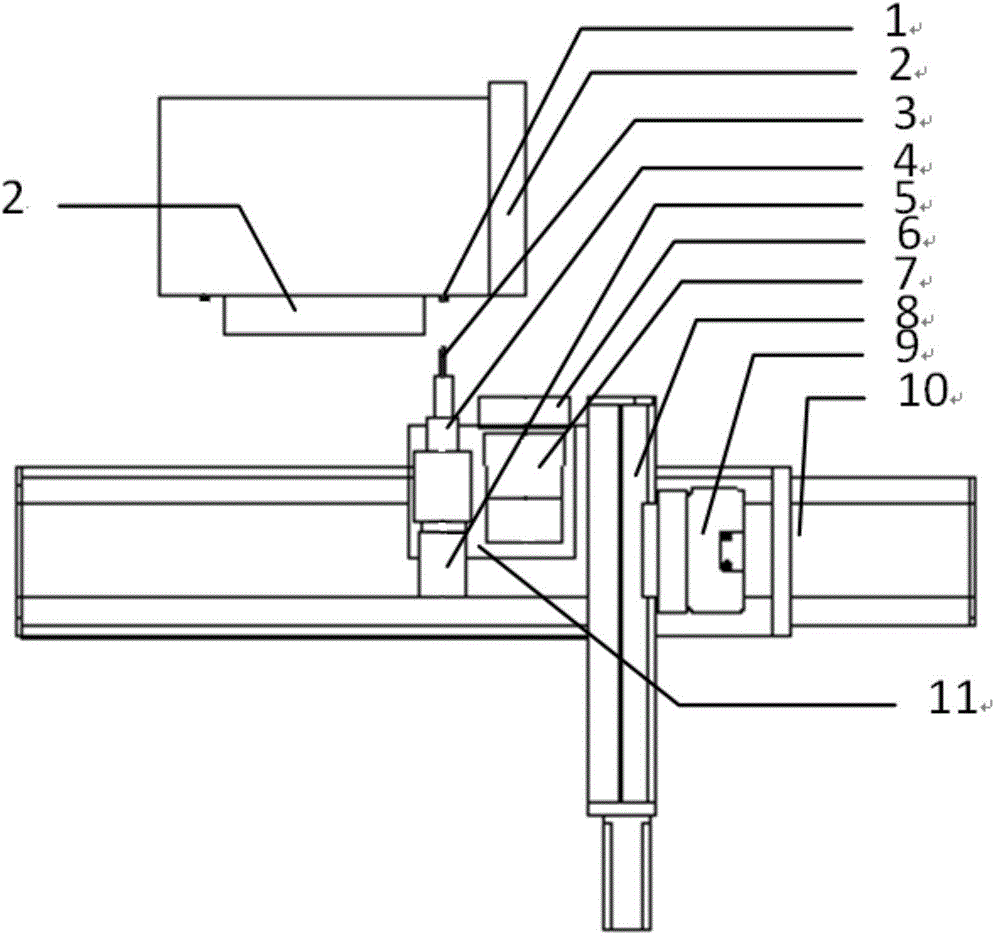

[0032] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

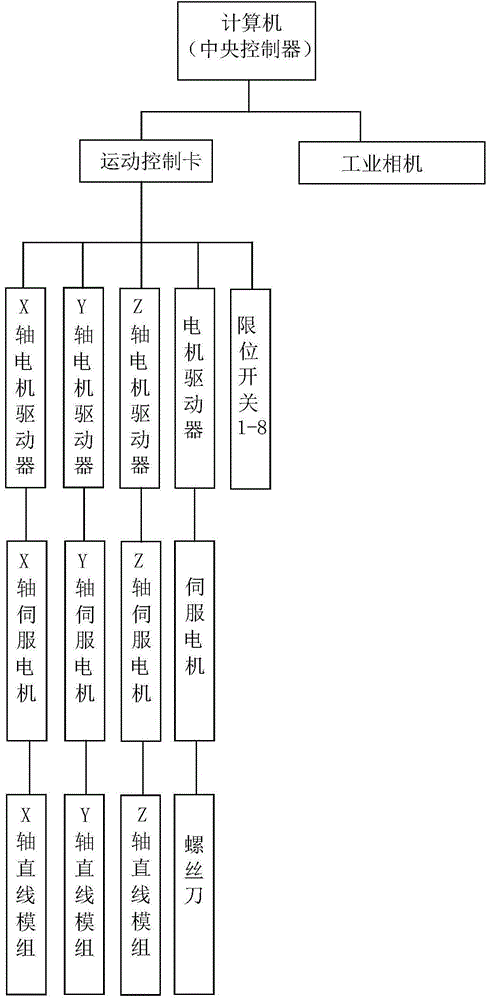

[0033] figure 1 It is a schematic diagram of the overall structure of the present invention. Such as figure 1 As shown, the present invention discloses a method and device for automatically removing screws based on visual positioning and torque control. The method includes a central controller controlling an industrial camera through a network card, collecting limit sensor signals through a motion control card, and controlling four servo motor drivers , where three motors are used for three-axis position movement, and the fourth motor is used to drive the screwdriver to rotate.

[0034] The specific method includes the following steps:

[0035] (1) System reset, system self-test;

[0036] (2) The X and Y axis servo motor drives the linear module to move the industrial camera to the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com