Multicolor EVA injection mold

A mold and mold cavity technology, applied in the field of multi-color EVA injection molds, can solve the problems of backward production process, increase of production cost, waste of resources, etc., and achieve the effects of reducing production cost, improving practicability, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

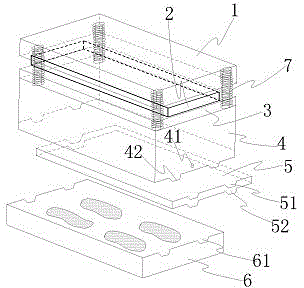

[0017] refer to figure 1 , the embodiment of the present invention discloses that the multi-color EVA injection mold includes, from top to bottom, a hanging plate 1, a backing plate 2, a sealing plate 3, an upper mold 4, a middle plate 5 and a lower mold 6, and the upper mold 4 and the lower mold 6 are located on the opposite side and are provided with mold cavities, and the upper mold 4 is also provided with a material injection port 41 communicating with the mold cavity, and the middle plate 5 is a detachable device. Between the upper mold 4 and the lower mold 6; two first positioning protrusions 42 are respectively provided on both sides of the lower surface of the upper mold 4, and two first positioning recesses are respectively provided on both sides of the upper surface of the lower mold 6. Groove 61, two second positioning grooves 51 are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com