Belt cleaning device for belt conveyor of normal concrete pouring tunnel lining trolley

A belt conveyor and lining trolley technology, which is applied to cleaning devices, conveyor objects, transportation and packaging, etc., can solve the problems of belt conveyor damage, difficulty in cleaning, frequent belt conveyor failures, etc., to avoid belt conveyor failures, The effect of ensuring the operation of the belt and facilitating the cleaning in place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

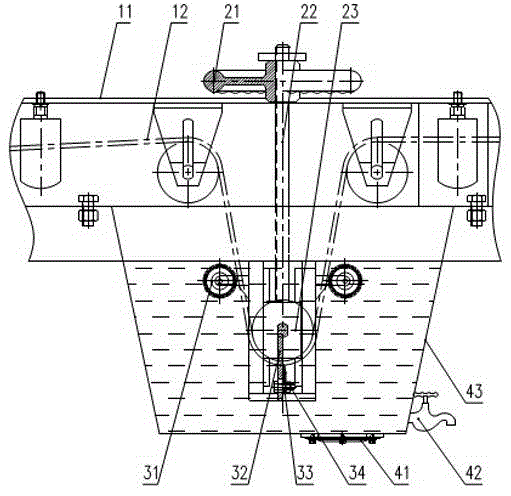

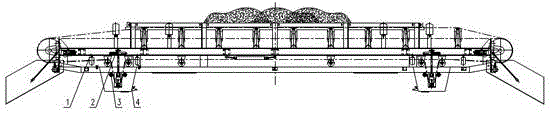

[0027] In conjunction with accompanying drawing 1 and accompanying drawing 2, a kind of normal concrete casting tunnel lining trolley belt conveyor belt cleaning device includes a belt tensioning mechanism 2 installed on a frame 11, a cleaning mechanism 3 and a water tank 4, and the cleaning mechanism 3 is located at In the water tank 4, the belt tensioning mechanism 2 cooperates with the cleaning mechanism 3, so that the belt 12 enters the cleaning mechanism 3 of the water tank 4 through the steering wheel, and is discharged from the water tank 4 through the steering wheel, and the frame 11 is fixedly installed on the belt conveyor;

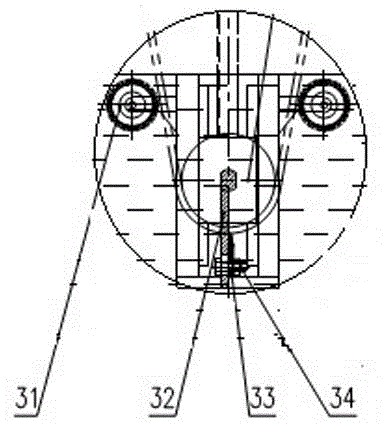

[0028] Such as image 3 Among them, the cleaning mechanism 3 includes a cleaning wheel 31, a knife holder 32, and a scraper 33. A plurality of cleaning wheels 31 are installed on both sides of the tensioning wheel 23 respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com