Lifts

A lifting platform and support platform technology, applied in the field of lifting platform, can solve the problems of unsafety, high cost, unstable lifting, etc., and achieve the effect of high safety, simple structure and stable lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

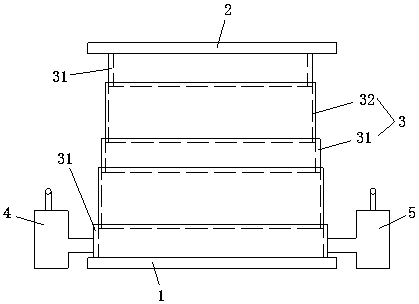

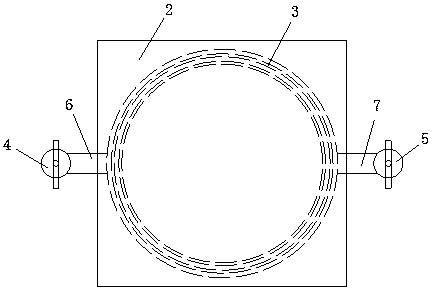

[0016] Such as figure 1 , figure 2 As shown, a telescoping tube 3 is arranged between the supporting platform 1 and the loading platform 2 .

[0017] In the case of setting a telescopic tube, the trachea includes first and second tubes 6, 7, one end of the first tube 6 is connected to the booster valve 4, and the other end of the first tube 6 is connected to the lowermost hard tube of the telescopic tube 3. The solid annular pipe 31 communicates, one end of the second pipe 7 links to each other with the pressure relief valve 5, and the other end of the second pipe 7 communicates with the hard annular pipe 31 at the bottom of the telescopic tube 3. That is to say, the first and second pipes are directly connected to the pipe wall of the hard annular pipe connected with the supporting platform, and the booster valve, the pressure relief valve, the telescopic pipe and the first and second pipes form a closed cavity.

Embodiment 2

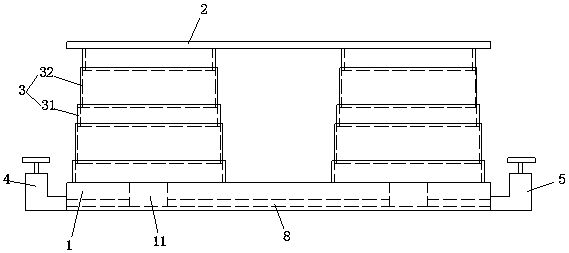

[0019] Such as image 3 , Figure 4 As shown, four telescopic tubes 3 are evenly arranged between the supporting platform 1 and the loading platform 2 .

[0020] In the case of setting four telescopic tubes, the supporting platform 1 is provided with four circular holes 11 respectively connected with the inner cavities of the four telescopic tubes 3. Preferably, the four circular holes should be arranged concentrically with the four telescopic tubes. Comprising connecting pipes 8 communicating with four circular holes 11 respectively, the connecting pipes 8 are arranged inside the support platform 1, that is, the four circular holes are connected through four connecting pipes 8 inside the supporting platform, and the four circular holes are connected with the four circular holes. The inner cavity of the root telescopic tube is communicated, and the connecting pipe 8 is provided with a booster valve 4 and a pressure relief valve 5, that is, the booster valve 4 and the pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com