A kind of halogen-free intrinsically flame-retardant rigid polyurethane foam and its preparation method

A technology of rigid polyurethane and foamed plastics, applied in the field of foamed plastics, can solve the problems of core burning, mechanical properties of rigid polyurethane foamed plastics, influence of thermal insulation performance, poor compatibility of foamed substrates, etc., and achieves low cost, simple preparation method, The effect of improving flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

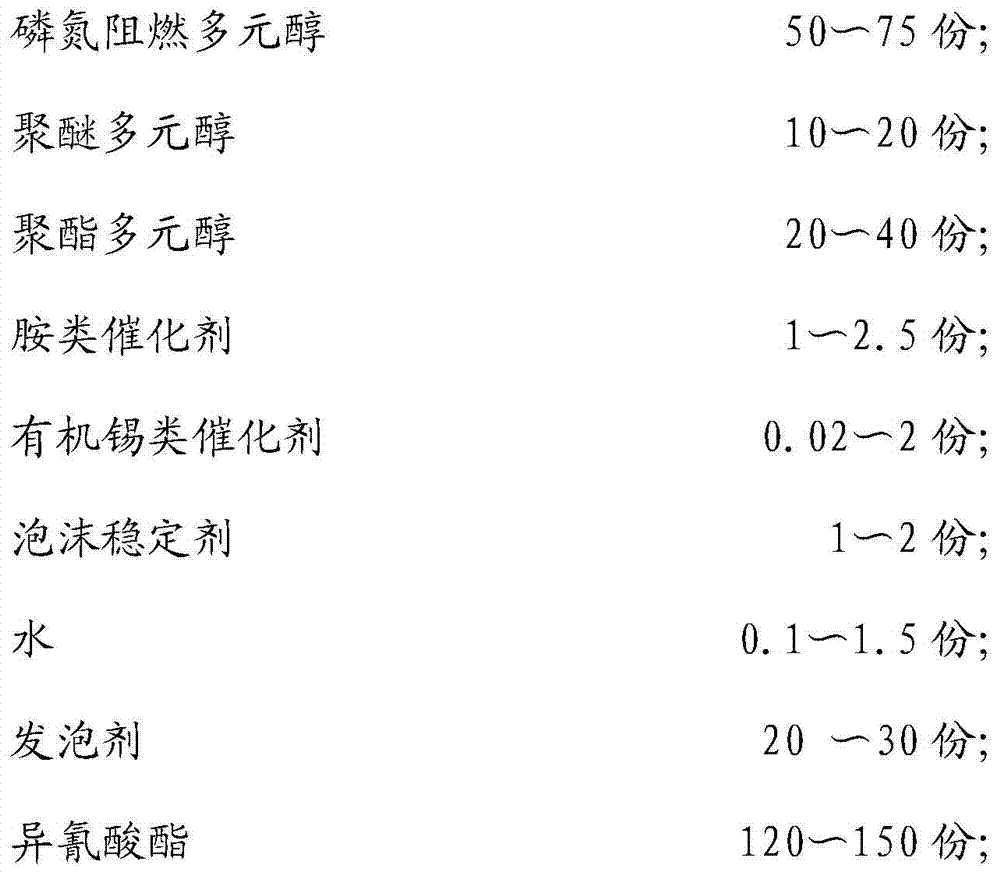

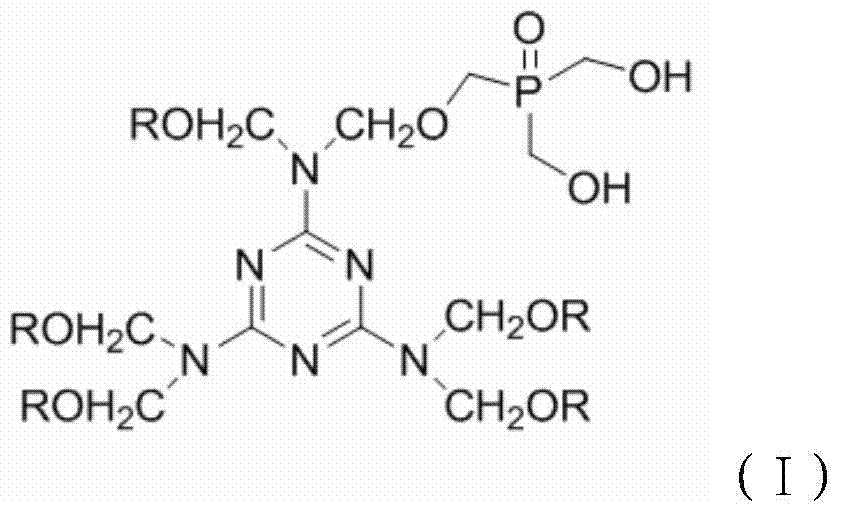

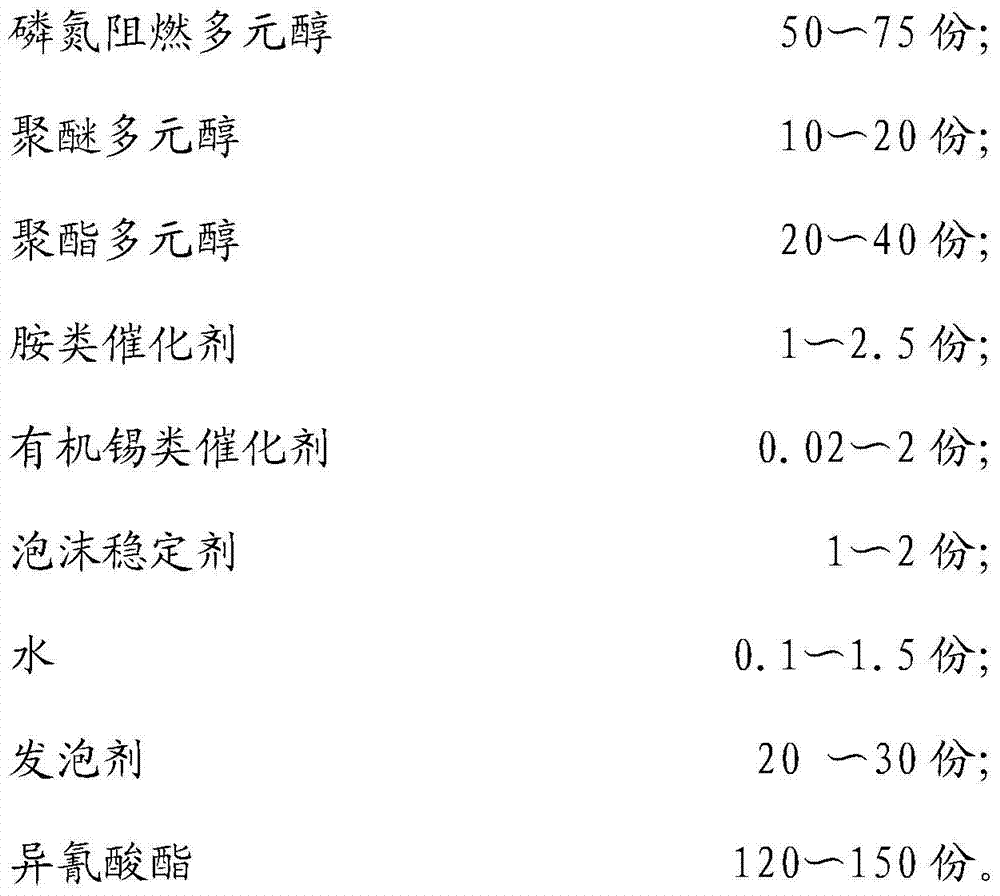

Method used

Image

Examples

Embodiment 1

[0033] 1) Weigh 50g of phosphorus nitrogen flame retardant polyol, 20g of polyether polyol 4110, 30g of phthalic anhydride polyester polyol PS-3152, 1.0g of N,N-dimethylcyclohexylamine, 0.02g of dibutyltin dilaurate, 1.0g of foam stabilizer AL-5309, 0.1g of water and 25g of chlorodifluoroethane (HCFC-141B) were uniformly mixed to obtain a polyurethane composition;

[0034] 2) Quickly add 130g of polymethylene polyphenyl isocyanate (PAPI) into the polyurethane composition, stir and mix evenly at a high speed at room temperature 2500r / min, when the mixture is observed to be whitish, it is poured into a self-made mould. Foaming, foaming temperature 25°C, relative humidity 25% to 50%, aging for 48 hours (ie 2 days) after foaming, and then demoulding, to obtain halogen-free intrinsically flame-retardant rigid polyurethane foam. The obtained product is measured according to GB-T2406-93 "Plastic Combustion Performance Test Method Oxygen Index Method" and the oxygen index is 25.5.

...

Embodiment 2

[0039] 1) Weigh 55g of phosphorus nitrogen flame retardant polyol, 15g of polyether polyol 4110, 30g of phthalic anhydride polyester polyol PS-3152, 1.0g of N,N-dimethylcyclohexylamine, 0.02g of dibutyltin dilaurate, 1.0g of foam stabilizer AL-5309, 0.1g of water and 25g of chlorodifluoroethane (HCFC-141B) were uniformly mixed to obtain a polyurethane composition;

[0040]2) Quickly add 130g of polymethylene polyphenyl isocyanate (PAPI) into the polyurethane composition, stir and mix evenly at a high speed at room temperature 2500r / min, when the mixture is observed to be whitish, it is poured into a self-made mould. Foaming, foaming temperature 25°C, relative humidity 25% to 50%, aging for 48 hours (ie 2 days) after foaming, and then demoulding, to obtain halogen-free intrinsically flame-retardant rigid polyurethane foam. According to GB-T2406-93 "Plastic Combustion Performance Test Method Oxygen Index Method", the obtained product has an oxygen index of 27.

[0041] In this ...

Embodiment 3

[0043] 1) Weigh 60g of phosphorus nitrogen flame retardant polyol, 10g of polyether polyol 4110, 30g of polyester polyol PS-3152, 1.0g of N,N-dimethylcyclohexylamine, 0.02g of dibutyltin dilaurate, 1.0g Foam stabilizer AL-5309, 0.1g water and 25g difluorochloroethane (HCFC-141B), mix uniformly to obtain polyurethane composition;

[0044] 2) Quickly add 130g of polymethylene polyphenyl isocyanate (PAPI) into the polyurethane composition, stir and mix evenly at a high speed at room temperature 2500r / min, when the mixture is observed to be whitish, it is poured into a self-made mould. Foaming, foaming temperature 25°C, relative humidity 25% to 50%, aging for 48 hours (ie 2 days) after foaming, and then demoulding, to obtain halogen-free intrinsically flame-retardant rigid polyurethane foam. According to GB-T2406-93 "Plastics Combustion Performance Test Method Oxygen Index Method", the obtained product has an oxygen index of 29.

[0045] In this embodiment, the phosphorus-nitroge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com