An adjustable double-rod pressing mechanism for warp knitting with double needle beds

A pressing mechanism and adjustable technology, which is applied in the field of warp knitting machines, can solve problems such as increased maintenance costs, high noise, and complicated cloth passing devices, and achieve the effects of reduced maintenance costs, good economic benefits, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

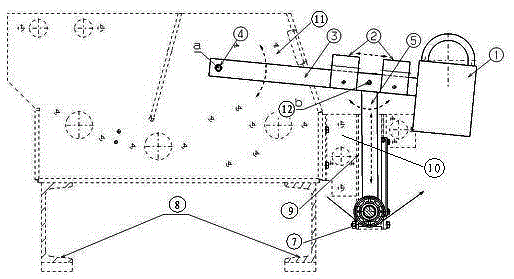

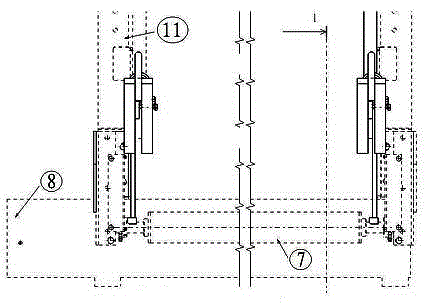

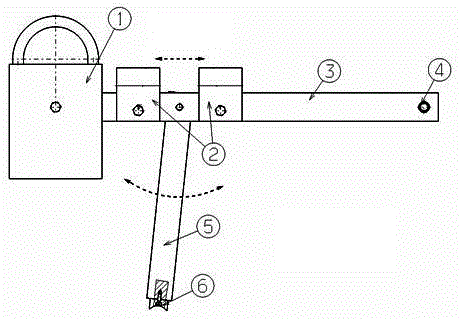

[0020] Such as figure 1 It is a structural schematic diagram of the present invention, a double-needle bed warp-knitted adjustable double-bar pressing mechanism, including a wallboard 11, a bracket 8 is provided under the wallboard 11, and a support plate is provided on the right side of the wallboard 11 10, a roller 7 is provided under the support plate 10 (such as figure 2 As shown), the wallboard 11 is provided with a guide rod 3, the guide rod 3 is provided with a pressure rod 5, one end of the guide rod 3 is fixed with a lock block 1 by a bolt, and the other end is provided with a ferrule 4. The guide rod 3 is provided with a U-shaped block 2 (such as image 3 , Figure 4 shown).

[0021] This double-needle bed warp-knitted adjustable double-bar pressing mechanism uses the weight of the lock block 1 to press the pressing bar 5 against the fabric during use, so that the fabric is closely attached to the roller 7. When the fabric is pulled It effectively avoids the lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com