Protection structure of high-speed overflowing surface and construction method thereof

A technology for protecting structures and construction methods, applied in coastline protection, water conservancy engineering, sea area engineering, etc., can solve the problem that high-strength concrete is difficult to achieve anti-scouring and wear-resistant spillway safety, which affects the service life of engineering permanent buildings. Engineering safety, spillway concrete To improve the quality and appearance, to improve the design concept, to avoid the problem of temperature stress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is a design and construction scheme of a spillway or a similar high-speed flow surface. The present invention will be further described in detail below, which is an explanation of the present invention rather than a limitation.

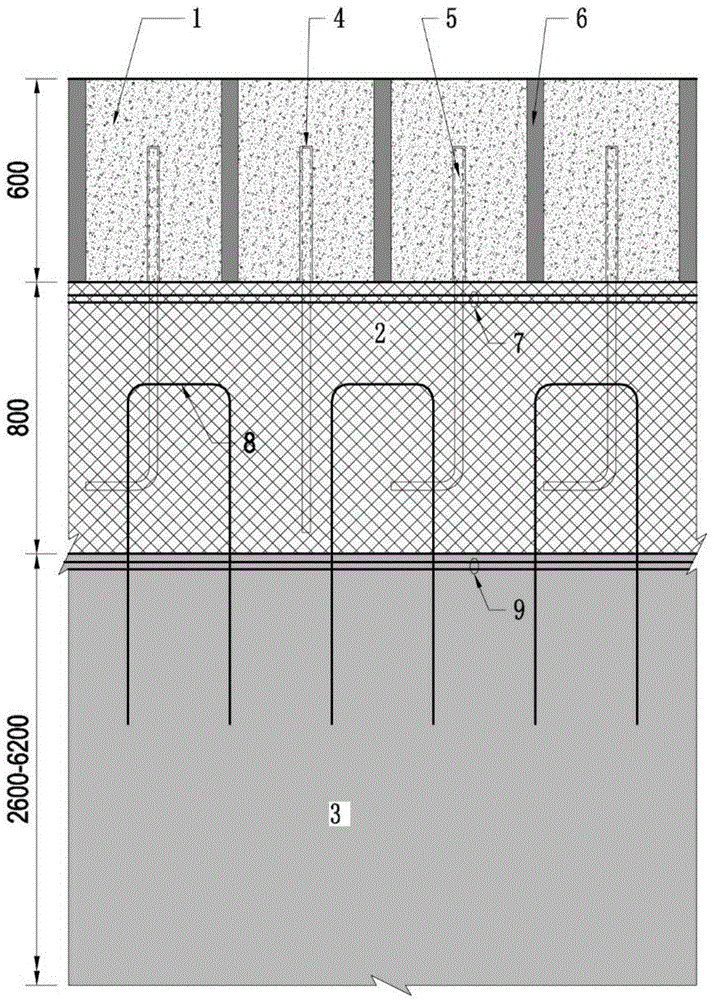

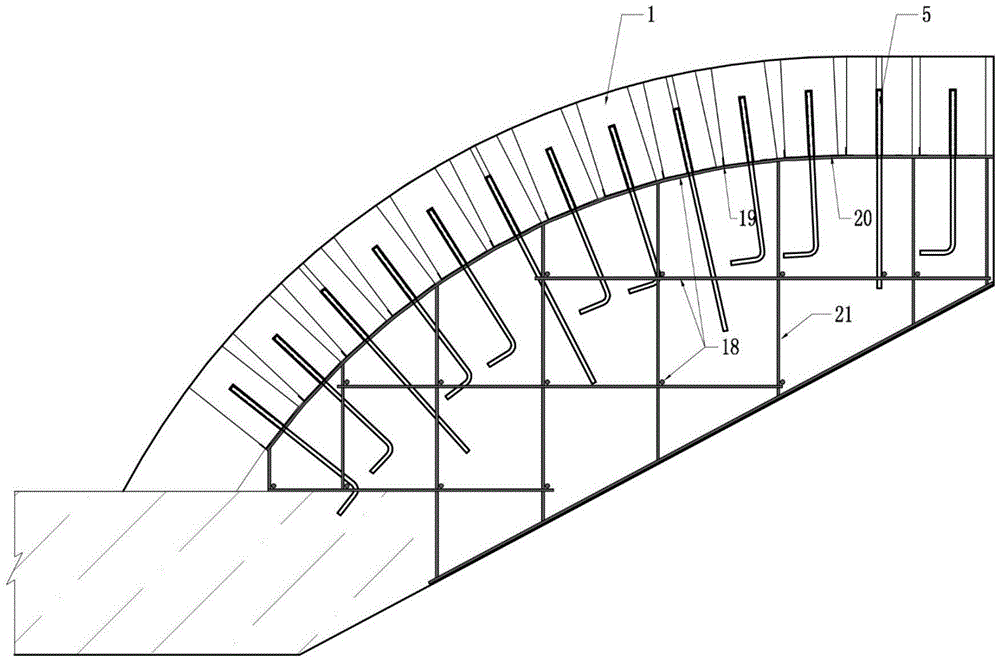

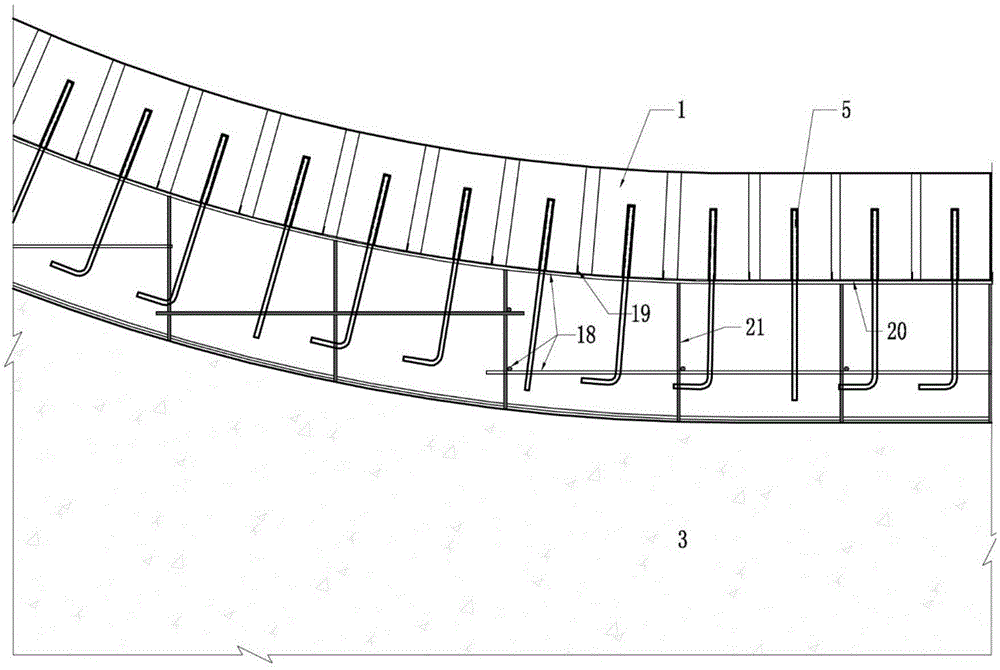

[0039] Such as figure 1 Shown, be the protection structure of a kind of high-speed flow surface of the present invention, the spillway floor structure (high-speed flow surface protection structure) as permanent structure is made of three-layer structure, comprises the natural granite 1 of protection surface layer, the intermediate transition layer The second phase of high-strength E50 dual-fiber concrete 2, and the first phase of base C30 normal concrete 3. There is a gap between adjacent granite 1, and the gap is filled with gap concrete (high-strength double-fiber concrete) 6 . When the first-stage concrete 3, the second-stage concrete 2 and the granite 1 constitute the floor of the spillway, different forms of steel ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com