Power rat hole device applicable to butting strings of well drilling platforms

A drilling platform and mouse hole technology, which is applied to drill pipes, drilling equipment, drill pipes, etc., can solve the problems of complex structure, installation height of lifting mechanism, and large space occupation, and achieves small layout space, simple and novel design, and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

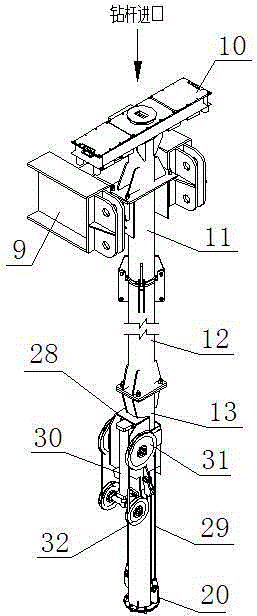

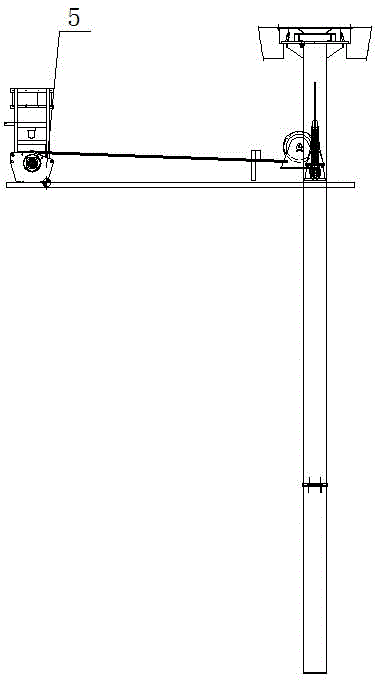

[0026] This embodiment provides a kind of power rathole device suitable for the docking of drilling platform pipe string, such as Figure 4~Figure 6 Shown, comprise laying platform 10, mouse hole pipe, drill pipe lifting table, mouse hole pipe mouth place is provided with clamping mechanism.

[0027] The rathole pipe includes three sections of upper, middle and lower rathole pipes. The upper rathole pipe 11 is installed on the derrick girder 9 to bear the dead weight of the drill pipe and the lower steel pipe; the upper and lower ends of the middle rathole pipe 12 pass through the flange respectively. Connect with locating pin with upper mouse hole pipe 11, lower mouse hole pipe 13. Segmented rathole tubing reduces transport length.

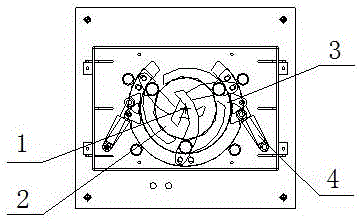

[0028] The clamping mechanism is installed at the top opening of the upper mouse hole pipe 11, such as Figure 7 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com