Profiled clamp

一种异形、夹头的技术,应用在异形夹领域,能够解决不好外观、收紧力异形夹-法兰系统分散性/变化影响、头部接触片意外变形等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

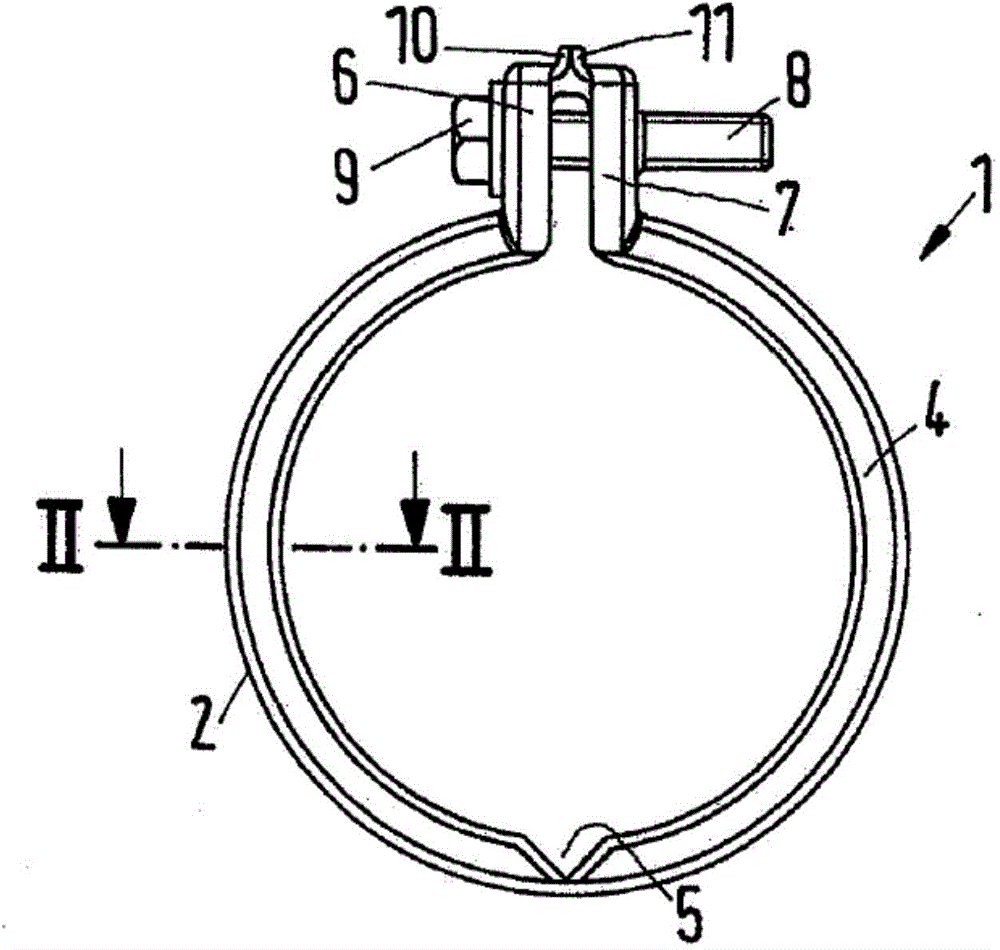

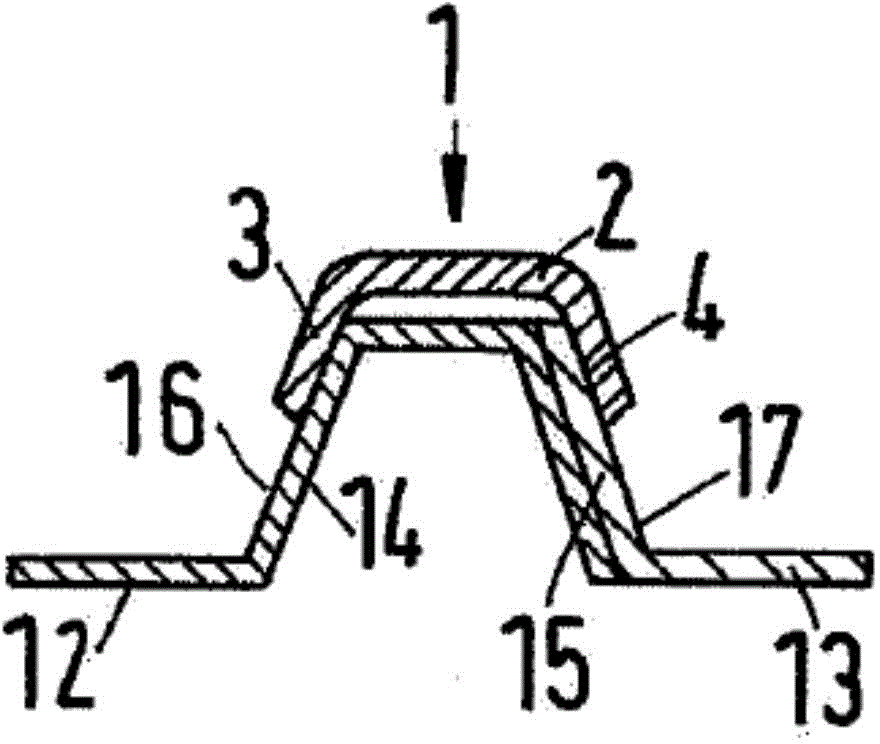

[0017] The profile clip 1 has a clip 2 which has radially inwardly running sides 3 , 4 at its axial ends. Such as figure 1 As shown, the sides can have interruptions 5 in the circumferential direction, whereby the clip 2 can be bent. However, the clip 2 can also be constructed in the circumferential direction from several parts.

[0018] The clamp 2 has a clamping head 6 , 7 at its two circumferential ends respectively. A tightening device in the form of a bolt 8 is guided through the collet 6 and is screwed onto a thread on the other collet 7 . Of course, the nut can also be screwed onto the end of the screw 8 protruding from the collet 7 . The screw 8 has a head 9 which, as in figure 1 In the shown tightened state, it bears against the outside of the collet 6 (in the circumferential direction).

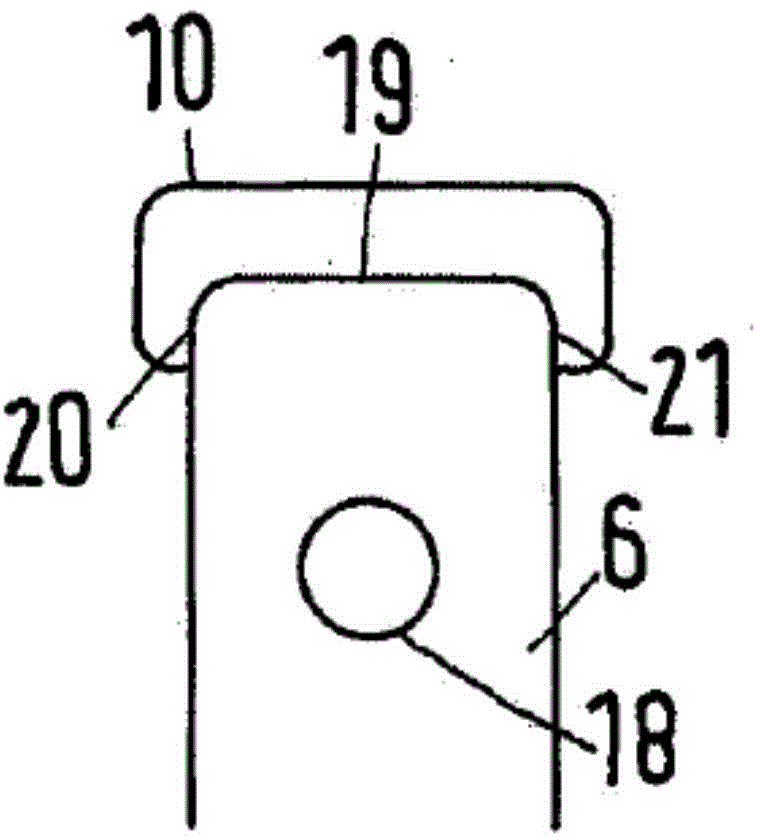

[0019] Each collet 6 , 7 has a head contact piece 10 , 11 . The two head contact pieces 10 , 11 abut against each other in the tightened state of the profile clip. In this ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com