Adjustable light beam automobile headlight

A technology for automobile headlights and light beams, which is applied to headlights, electric light sources, motor vehicles, etc., can solve the problem of low adjustment accuracy, and achieve the effects of high adjustment accuracy, good adjustment effect, and reduction of the influence of light sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

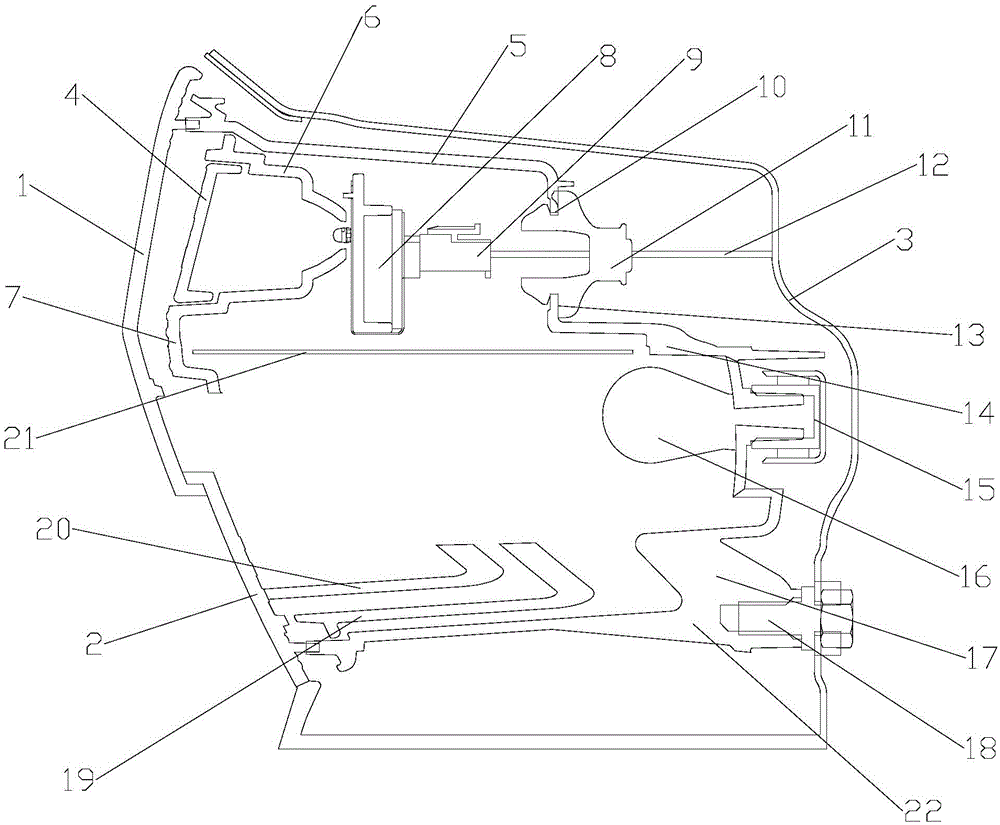

[0014] This embodiment includes a lamp housing 3, a short-focus lens 1, and a collimating mirror 2. The short-focus lens 1 is located between the lamp housing 3 and the collimating mirror 2, and the collimating mirror 2 is located between the short-focus lens 1 and the lamp housing 3. The lamp housing 3 is provided with a main light source 16 and an auxiliary light source 8, and a homogenizing partition 21 is arranged between the main light source 16 and the auxiliary light source 8. One side is provided with focusing lens 4, reflecting mirror A6, reflecting mirror B7, focusing lens 4 is located between reflecting mirror A6, reflecting mirror B7, the other side of auxiliary light source 8 is connected with micromotor 9, and micromotor 9 is connected with leading screw 12. The screw 12 is sleeved with a rotating piece 11, one side of the rotating piece 11 is connected with the short-focus lens 1 through the connecting rod A5, and the other side of the rotating piece 11 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com