Horizontal apparatus for component post seismic test

A component and experimental technology, applied in the direction of applying repeated force/pulsation force to test the strength of materials, etc., can solve the problem of high requirements for experimental equipment, achieve the effect of convenient operation, simple structure, and reduce adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

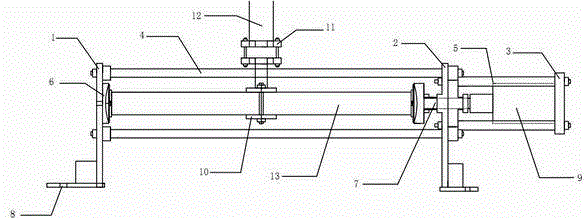

[0018] The technical solution of the present invention is described in further detail below in conjunction with the accompanying drawings of the description:

[0019] The low-cycle reciprocating load test device for structural columns includes three flange supports 1, 2, 3, two sets of tie rods 4, 5, the test piece 13 is fixed by the ball joint 6, and the test piece 13 is fixed in the middle of the flange supports 2, 3. The jack 9 applies a thrust to the adjusting screw to achieve the effect of applying an axial force to the test piece 13 . The thin tie rod is drawn out through the conversion plate to connect with the fixture 10, and the fixture is tightly fixed on the test piece by bolts.

[0020] Fig. 2 is a schematic diagram of the side and the front of the ball joint bearing. The ball joint 6 is divided into two parts, the bearing part and the movable part. The bearing part is a spherical concave surface, and the movable part is a spherical surface. There is a circular pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com