Device and method for measuring solid surface free energy in adsorption way

A solid surface, adsorption capacity technology, applied in the direction of measuring devices, surface/boundary effects, instruments, etc., can solve problems such as complex, difficult surface energy testing, uneven aggregate surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

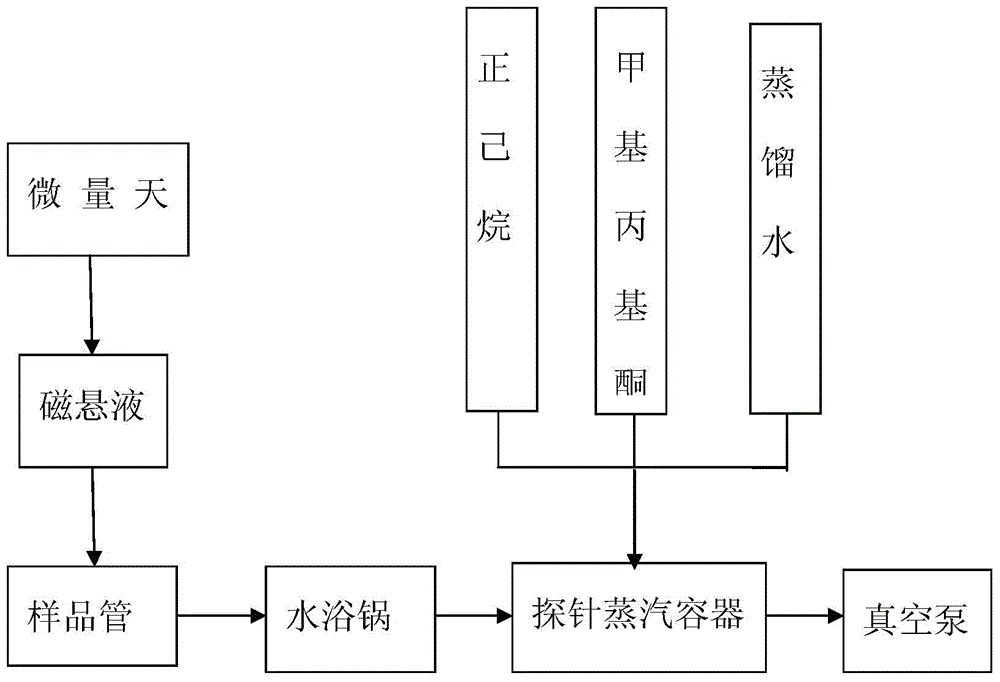

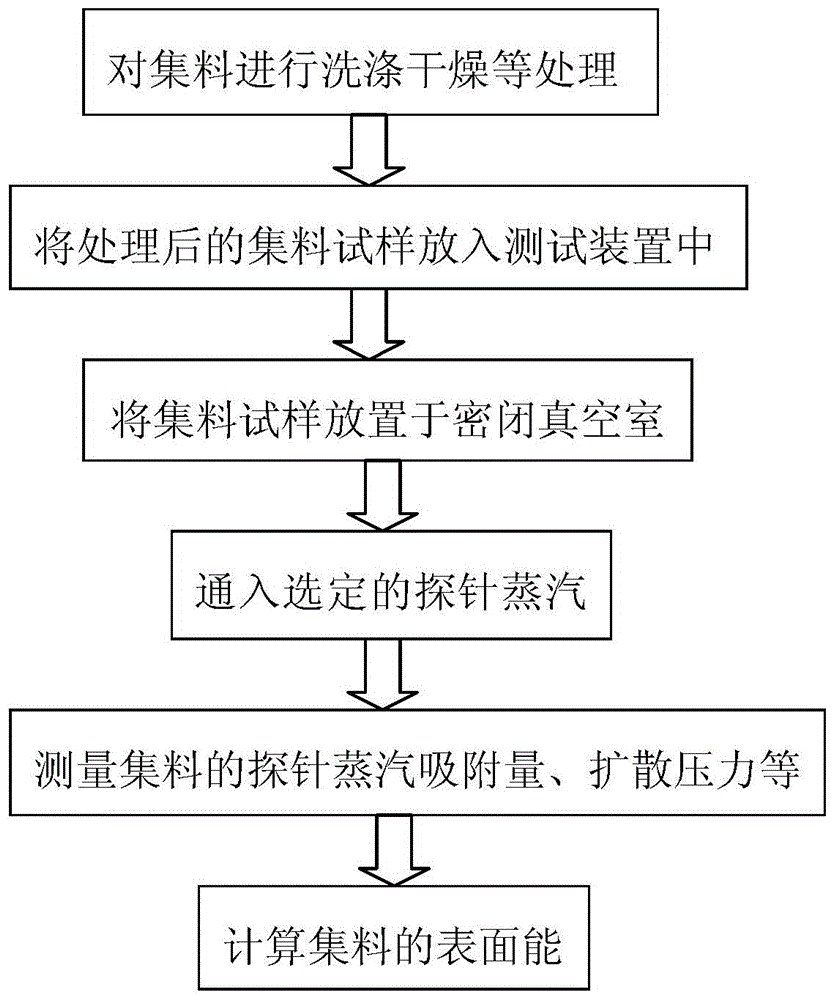

[0030] A method for measuring solid surface free energy by adsorption, comprising the steps of:

[0031] 1) After preparing the sample, place it in a sealed vacuum chamber. The vacuum chamber maintains a constant temperature of 25°C. The specific steps include: the sample is screened and the particle size is between 4.75mm-2.36mm, and then washed Cycle, the washing cycle includes first washing with distilled water, methanol and n-hexane in sequence, then washing with methanol again, drying in an oven at 150°C for 8 hours after the final washing, and drying at room temperature for at least 8 hours. ;

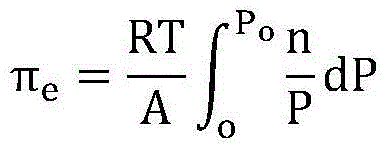

[0032] 2) The probe steam is released into the vacuum chamber, and the vacuum chamber maintains a constant temperature. The probe steam reaches the saturated vapor pressure P at different stages (that is, the time period divided by a certain time interval after the probe gas is introduced). o When measuring the probe vapor adsorption amount n on the surface of the sample at diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com