Circuit breaker

A circuit breaker and moving contact technology, which is applied to circuit breaker components, protective switch operation/release mechanisms, etc., can solve the problems of long arc movement time, reduced breaking capacity of circuit breakers, and poor arc extinguishing capacity of arc extinguishing chambers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

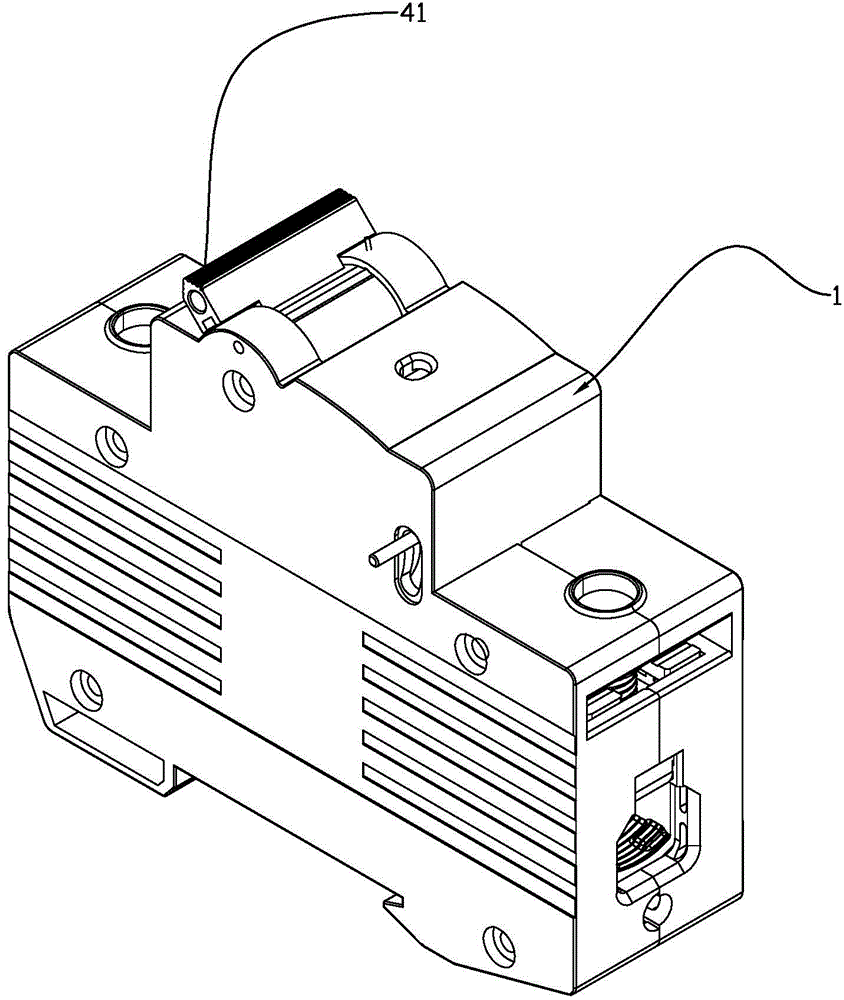

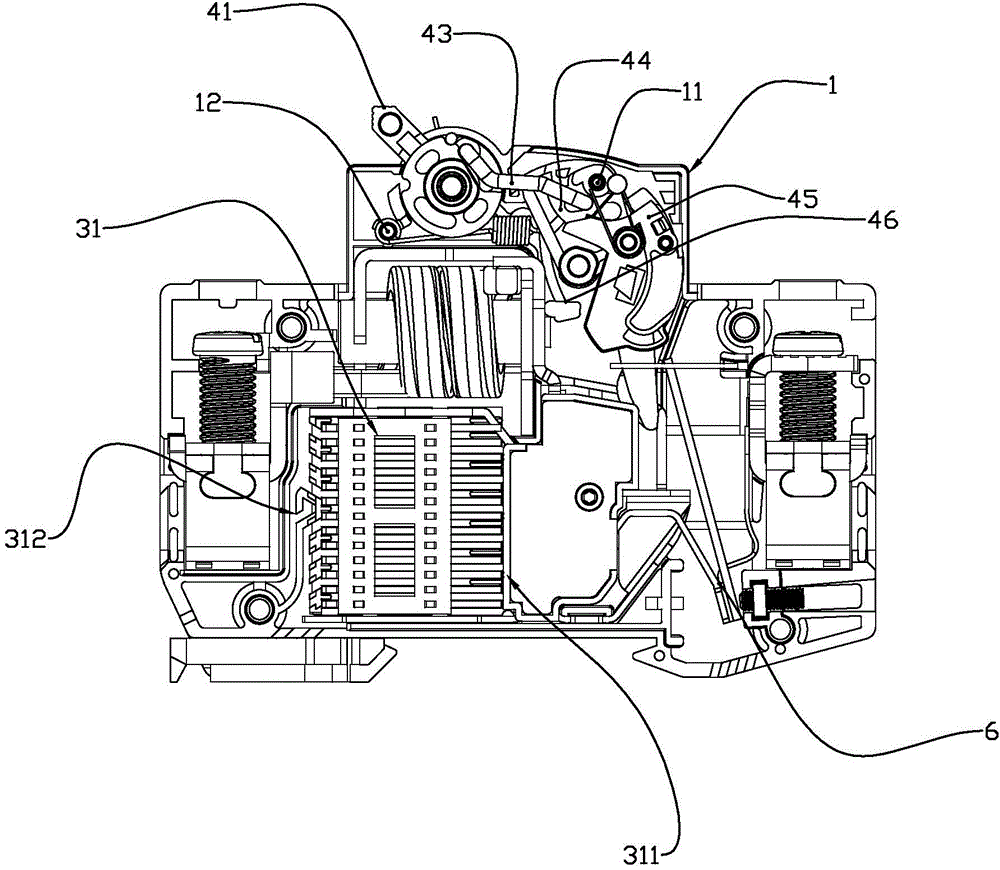

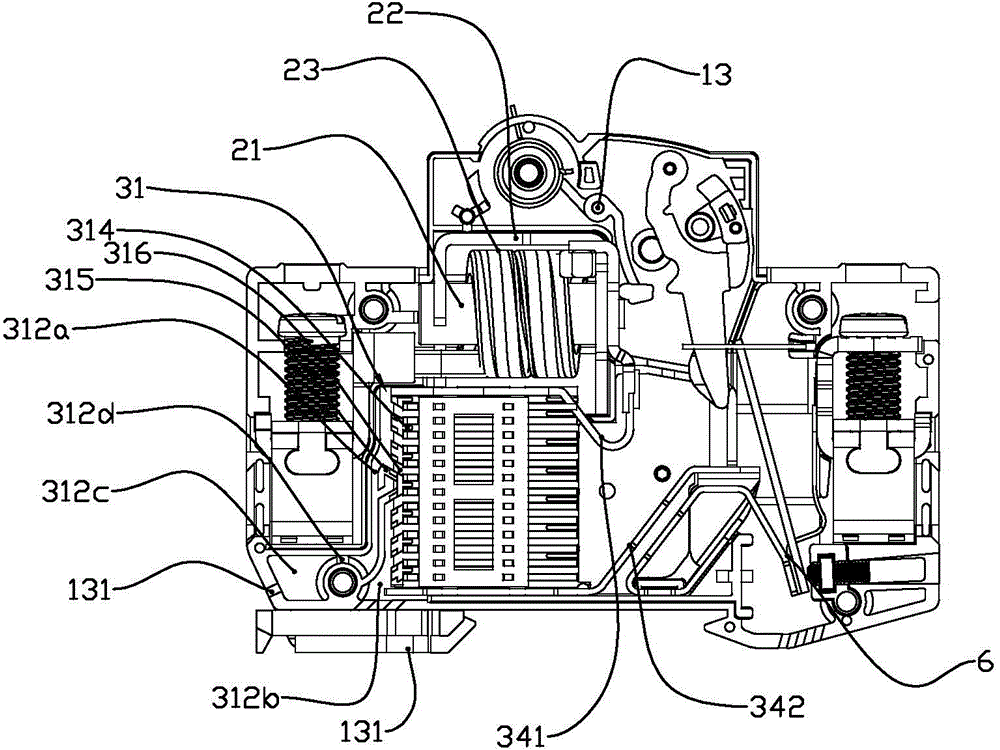

[0040]Specific embodiments of the present invention such as Figure 1-16 Shown is a circuit breaker, including a housing 1, a contact mechanism, an arc extinguishing system, an operating mechanism and a magnetic tripping mechanism. The contact mechanism includes a moving contact 51 and a static contact 52, and the moving contact 51 is provided with a moving contact At point 511, the static contact 52 is provided with a static contact 521. The arc extinguishing system includes an arc extinguishing chamber 31. The arc extinguishing chamber 31 is provided with an arc extinguishing grid 32, an arc extinguishing cover 33 and an arc strike assembly. The arc strike assembly includes an upper The arc leading piece 341 and the lower arc leading piece 342, one end of the upper arc leading piece 341 is located above the arc extinguishing chamber 31, and the other end of the upper arc leading piece 341 is bent upwards to connect with the static contact 52, and the static contact 521 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com