Cooling structure of air compressor motor

A heat dissipation structure, electromechanical technology, applied in electromechanical devices, machines/engines, electrical components, etc., can solve problems such as increased power consumption, reduced motor output power, and temperature rise of air compressor motors, so as to avoid ventilation and friction loss , increase output power, reduce volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

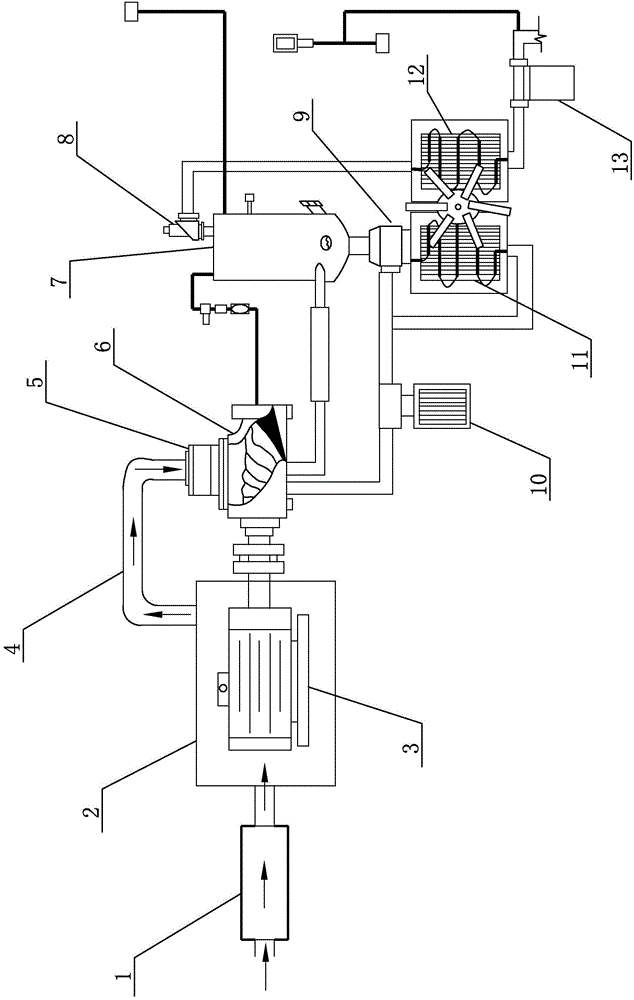

[0027] Such as figure 1 As shown, the heat dissipation structure of an air compressor motor provided by the present invention includes an air filter 1, a sealed box 2, an air intake pipe 4, an air volume regulating valve 5, and a compressor host 6 in sequence, and the compressor host 6 is driven by a motor 3. The motor 3 is arranged inside the sealed box 2 . When the compressor host 6 is working, an air pressure difference is formed between it and the outside air, and the air is inhaled through the intake pipe 4, and the inhaled air is first filtered by the air filter 1, and the filtered air is forced to the motor 3 in the sealed box 2. Convection cooling. When the output power of the motor 3 increases, the power of the compressor host 6 increases accordingly, and the air volume flowing through the surface of the motor 3 also increases, so as to ensure that the motors 3 of different powers are cooled.

[0028] The heat dissipation structure of the air compressor motor of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com