Heat dissipation structure of centrifugal pump

A heat dissipation structure and centrifugal pump technology, applied in the mechanical field, can solve problems such as affecting bearing life and reducing rotor rotation accuracy, and achieve the effects of extending structural life, prolonging aging speed, and improving heat dissipation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

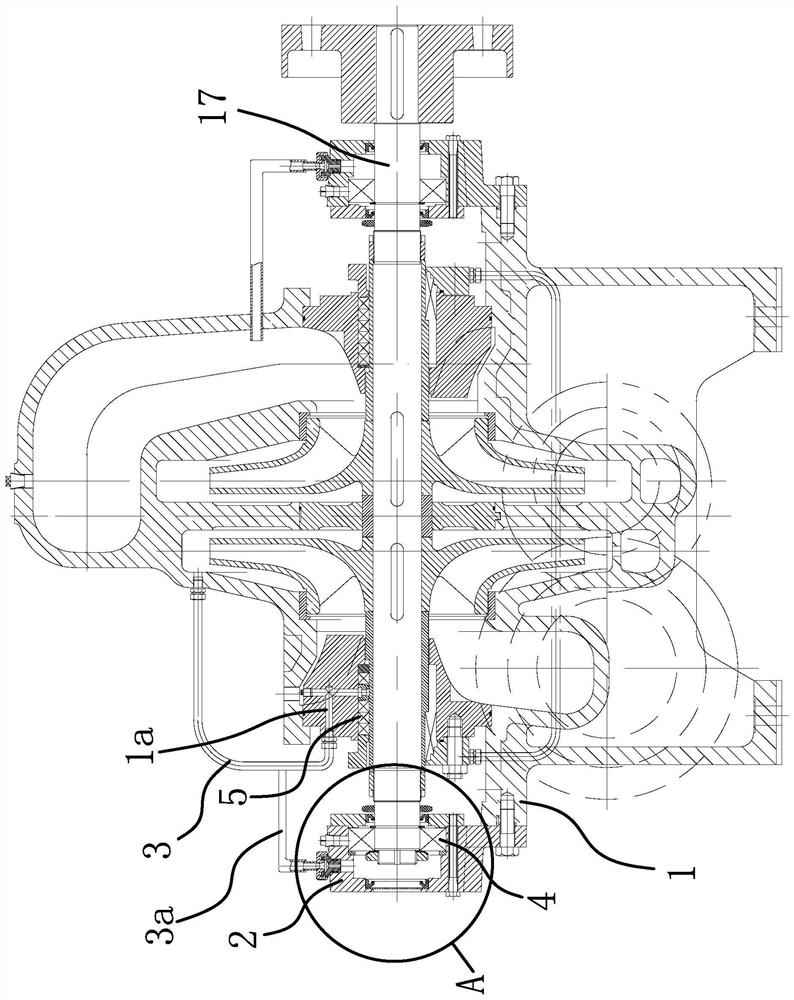

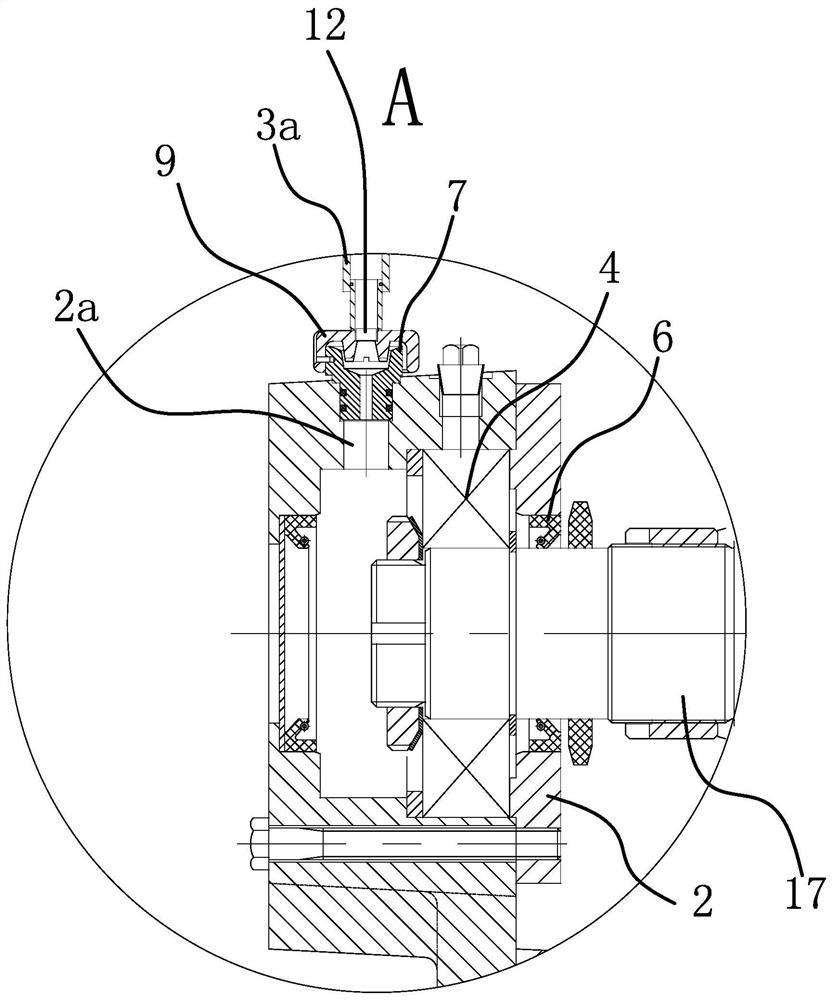

[0028] Such as figure 1 As shown, in the heat dissipation structure of the centrifugal pump, the centrifugal pump includes a pump body 1, a rotor 17 horizontally arranged in the pump body, a barrel body 2 and a flushing pipe 3 arranged outside the pump body 1, and the outer end of the rotor 17 protrudes from the pump body 1 And located in the bucket body 2, and the bucket body 2 and the rotor 17 are connected through the bearing 4. In this embodiment, the preferred type of bearing 4 is a rolling bearing 4 .

[0029] Among them, the outer end of the rotor 17 forms a seal with the pump body 1 through the mechanical seal 5, one end of the flushing pipe 3 communicates with the pump chamber of the pump body 1, and the pump body 1 is provided with a flow channel 1a for flushing the mechanical seal 5, and the flushing pipe 3 The other end communicates with flow channel 1a. In this embodiment, the connection methods of the mechanical seal 5 and the flushing pipe 3 to the flow channe...

Embodiment 2

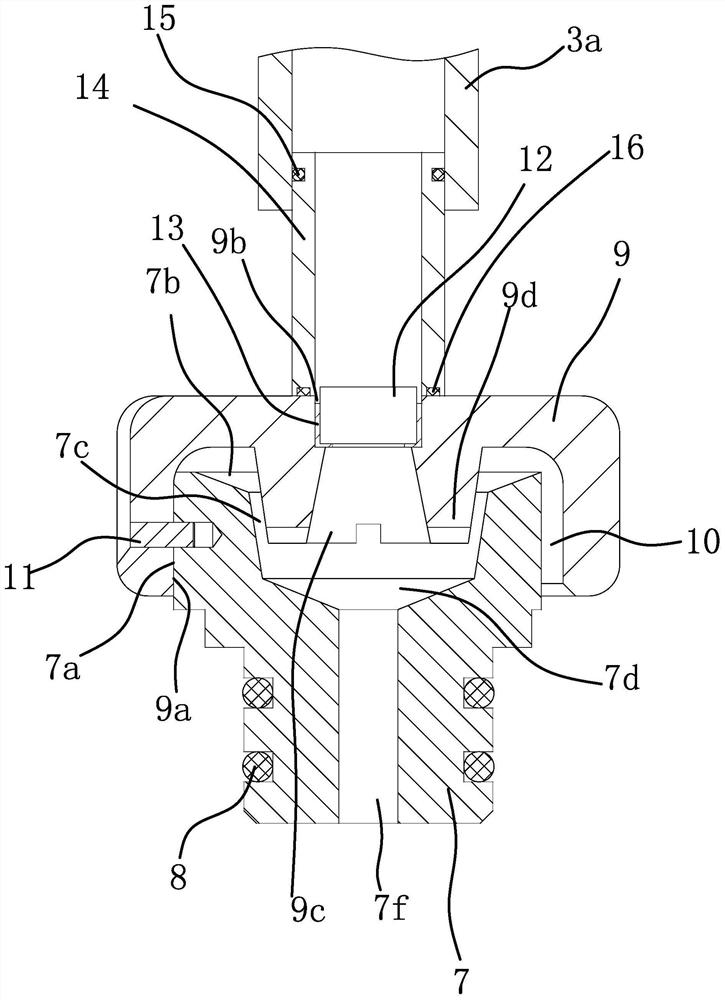

[0037] The structure and principle of this second embodiment are basically the same as that of the first embodiment, except that: one side of the outer wall at the upper end 7 of the oil pipe is a plane 7a, and the inner wall of the cover body 9 has a plane 2 9a that is in close contact with the plane 1 7a , there is threaded hole 2 horizontally running through plane 2 9a, and threaded hole 1 coaxial with threaded hole 2 is provided on plane 1 7a, the same bolt is screwed inside threaded hole 1 and threaded hole 2, and the head of the bolt is located in the cover 9 in vitro.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com