Fuel injection system comprising a fuel-guiding component, a fuel injection valve and a mounting

一种燃料喷射系统、燃料喷射阀的技术,应用在燃料喷射装置、特殊燃料喷射装置、具有降低噪音措施的燃料喷射装置等方向,能够解决噪声等问题,达到降低噪声、维持强度要求、改进悬置的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

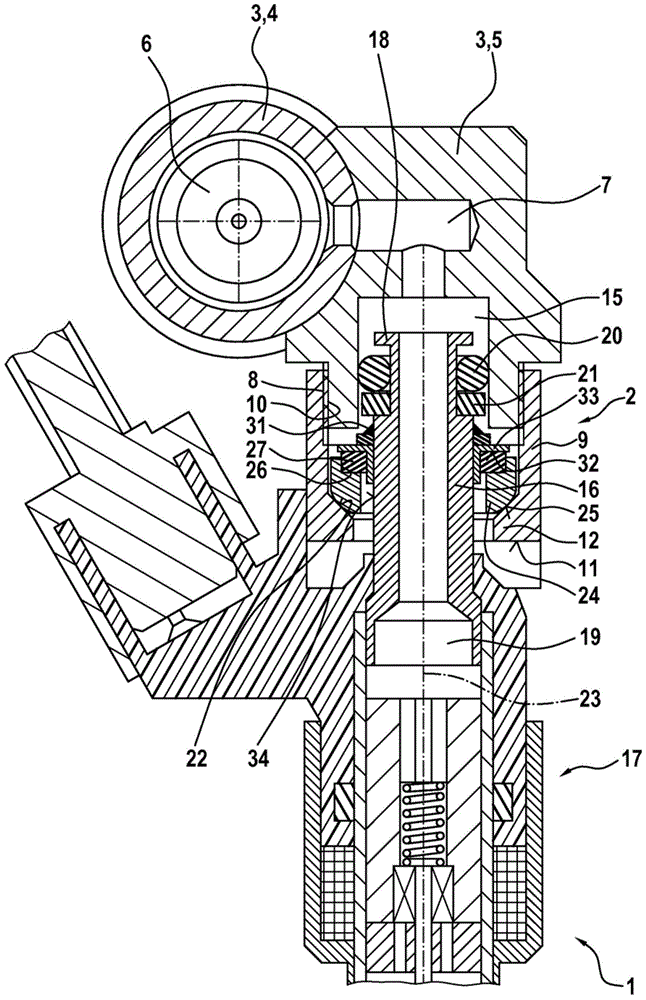

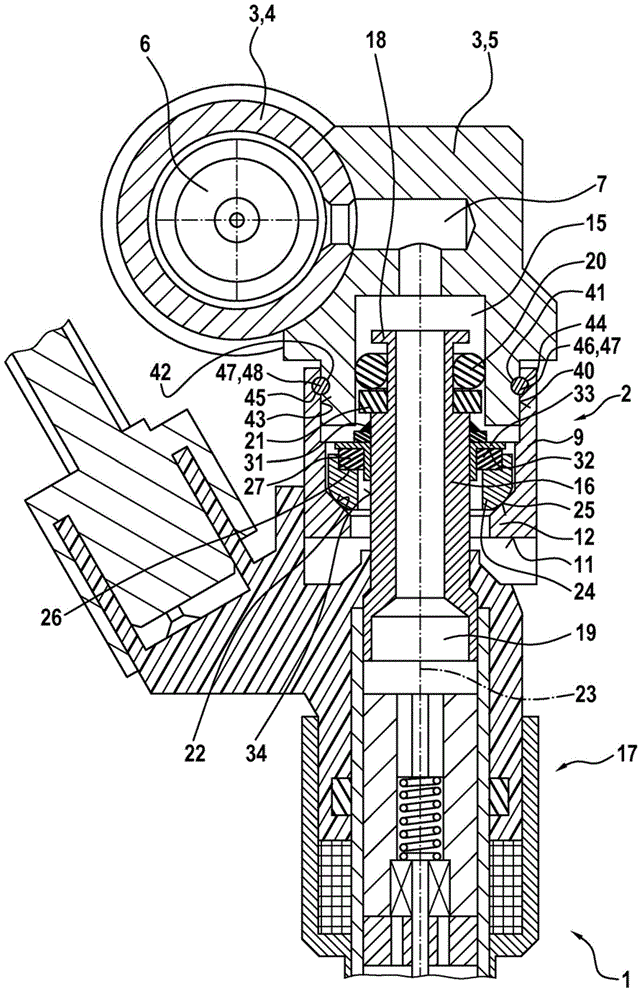

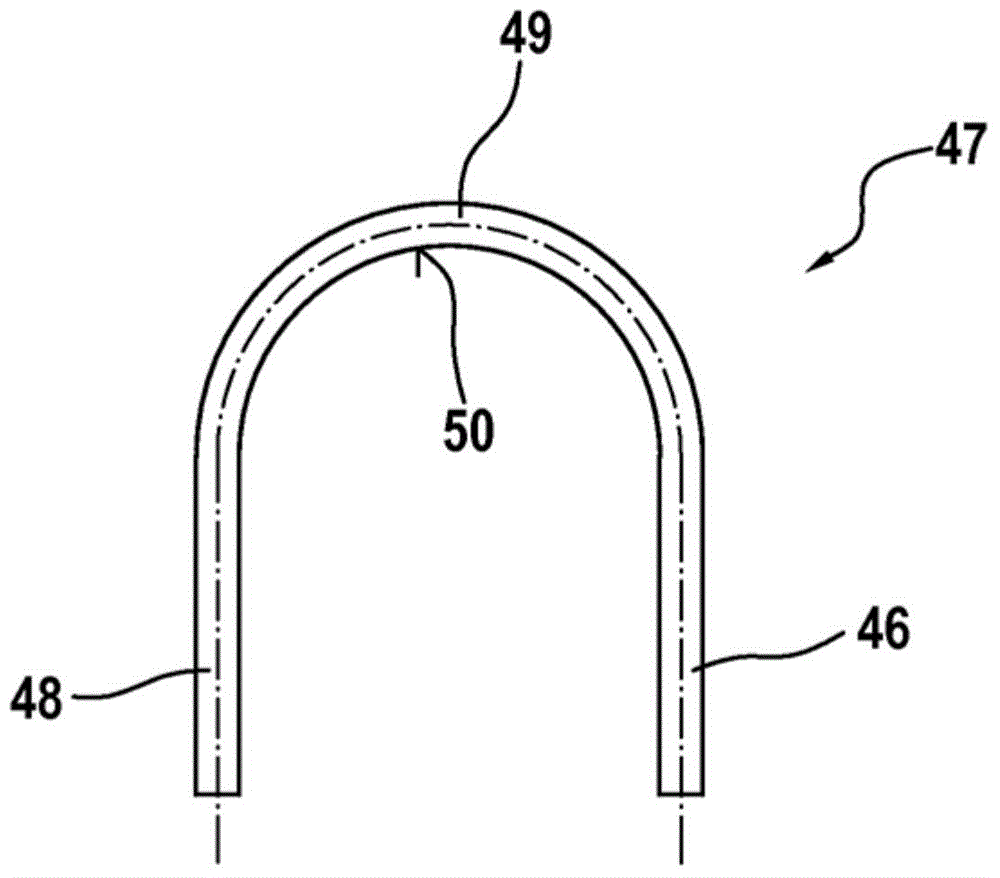

[0023] figure 1 A fuel injection system 1 with a suspension 2 is shown in a simplified, schematic sectional illustration according to a first exemplary embodiment. The fuel injection system 1 can be used in particular for high-pressure injection in internal combustion engines. The fuel injection system 1 can be used in particular in hybrid compression external ignition internal combustion engines. The suspension device 2 is particularly suitable for such a fuel injection system 1 .

[0024]The fuel injection system 1 has a fuel guide part 3 which, in the exemplary embodiment, is designed as a fuel distributor guide plate 3 . The fuel distributor guide plate 3 has a tubular base body 4 and a connecting body 5 . An elongated fuel chamber 6 is formed in the tubular base body 4 , from which a connecting channel 7 led by the connecting body 5 branches off. In this case, a further connecting body is preferably attached to the tubular base body 4 , said further connecting body ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com