A bone modification guide plate assembly for artificial temporomandibular joint replacement

A temporomandibular joint and guide plate technology is applied in the field of artificial temporomandibular joint replacement bone trimming guide plate components, which can solve the problems of reducing jaw strength, bone loss, nerve reduction, etc., so as to reduce bone loss and reduce the occurrence of complications. , the effect of increasing the degree of fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

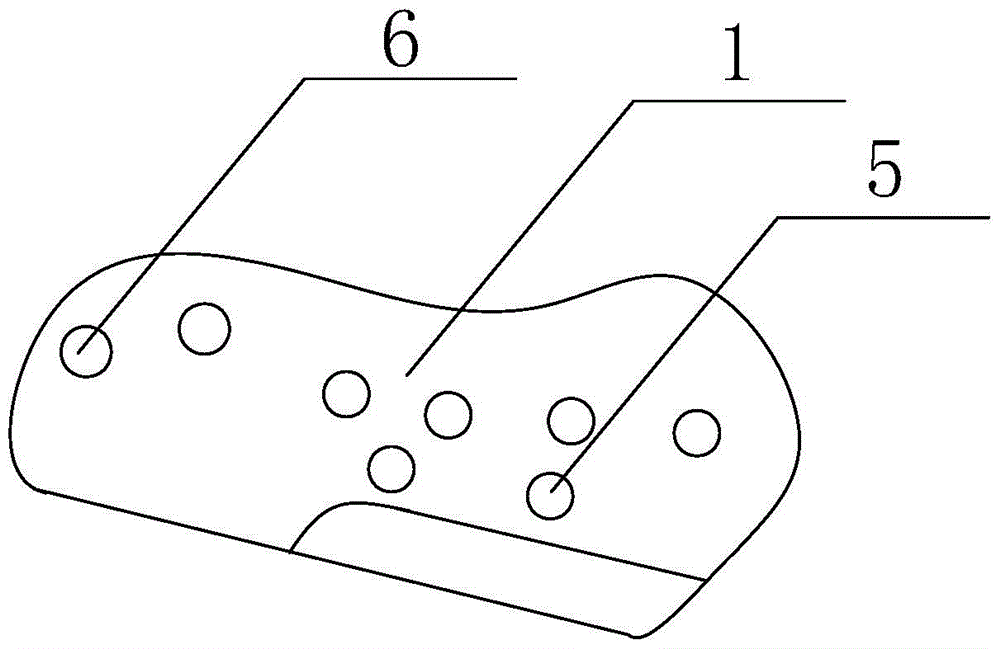

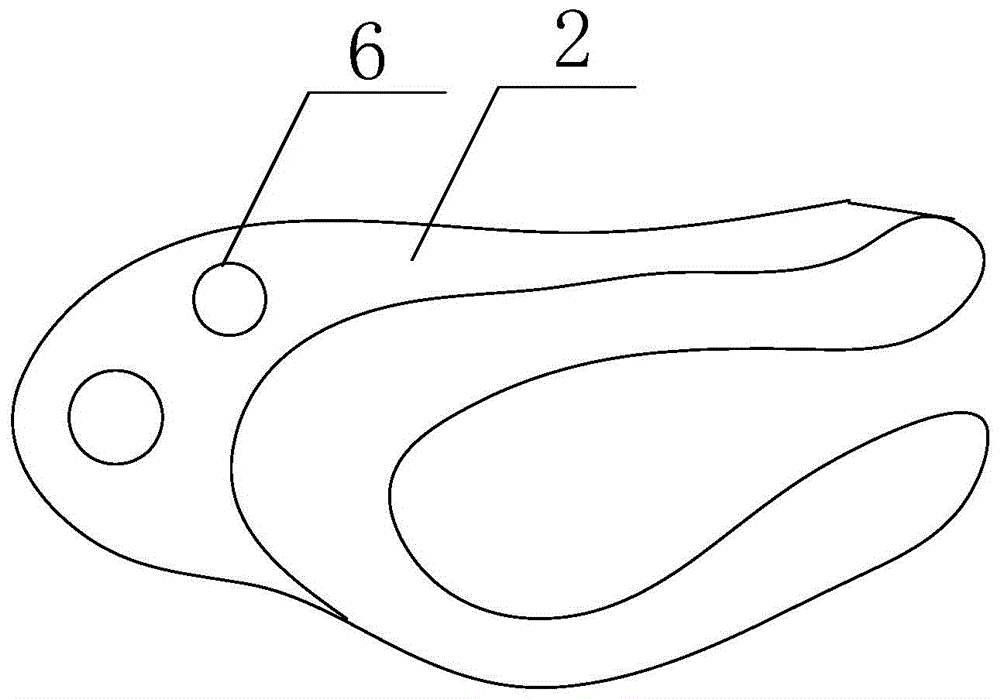

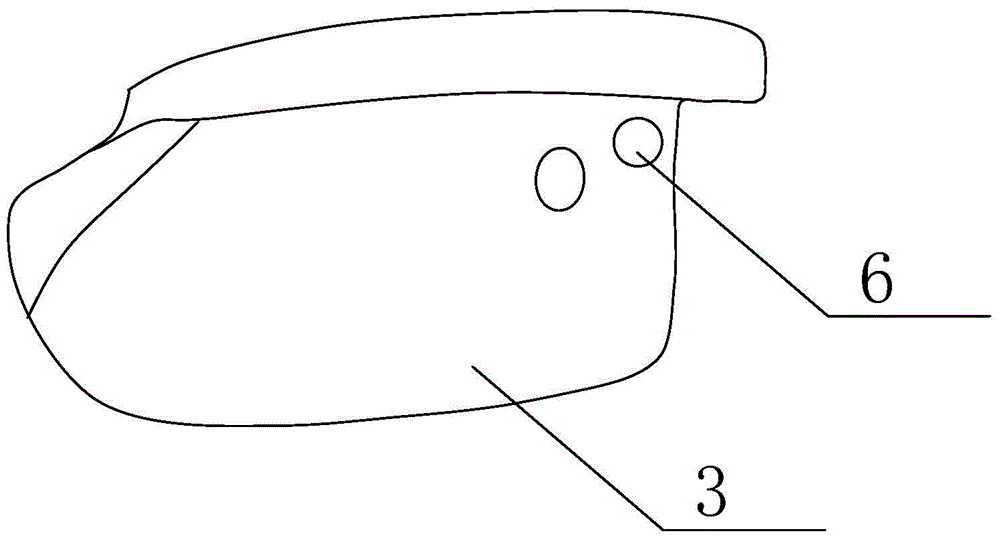

[0019] This embodiment is mainly used in total joint replacement treatment of temporomandibular joint ankylosis, advanced condylar osteoarthritis and various advanced condylar degeneration. Preoperatively, based on the patient's CT data, the three-dimensional reconstruction technology is used to accurately restore the patient's jaw bone model, and the matching prosthesis data is imported to simulate the implantation of the prosthesis on the digital jaw bone model, so as to determine the grinding position and range of the jaw bone , direction and depth; CAD / CAM technology is used to design the osteotomy guide plate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com