Iron removal device with automatic iron unloading function

A technology of iron remover and automatic unloading, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve problems such as vicious tearing of belt conveyors, iron falling into coal flow, electromechanical accidents, etc., to reduce labor intensity of employees, The effect of removing iron sundries, reducing power consumption and equipment loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with examples. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

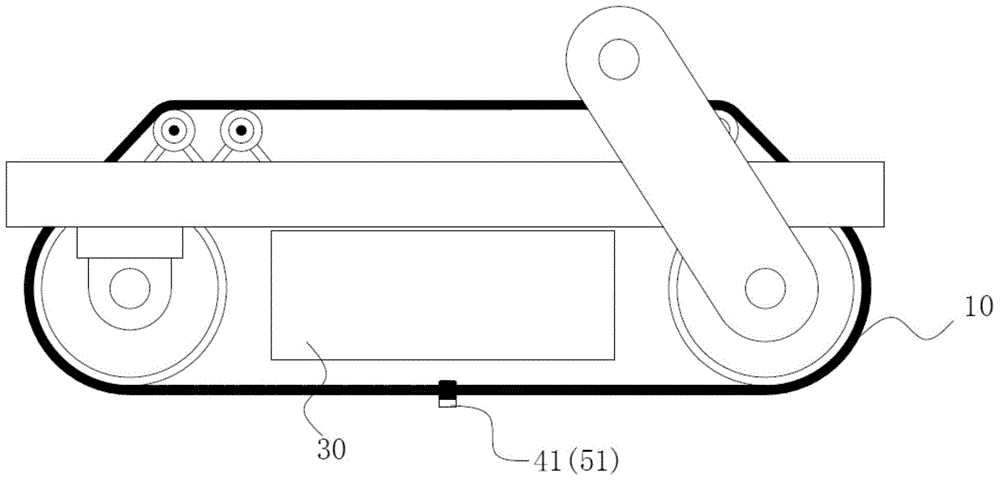

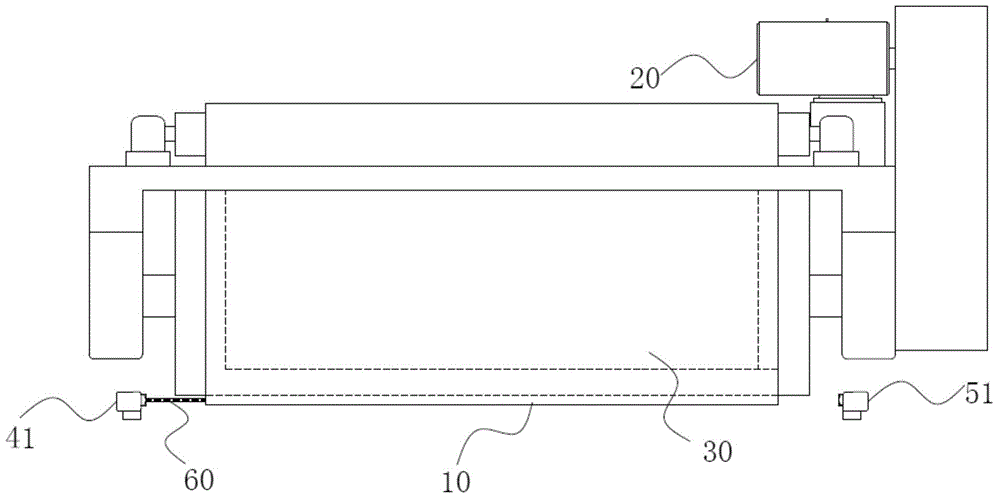

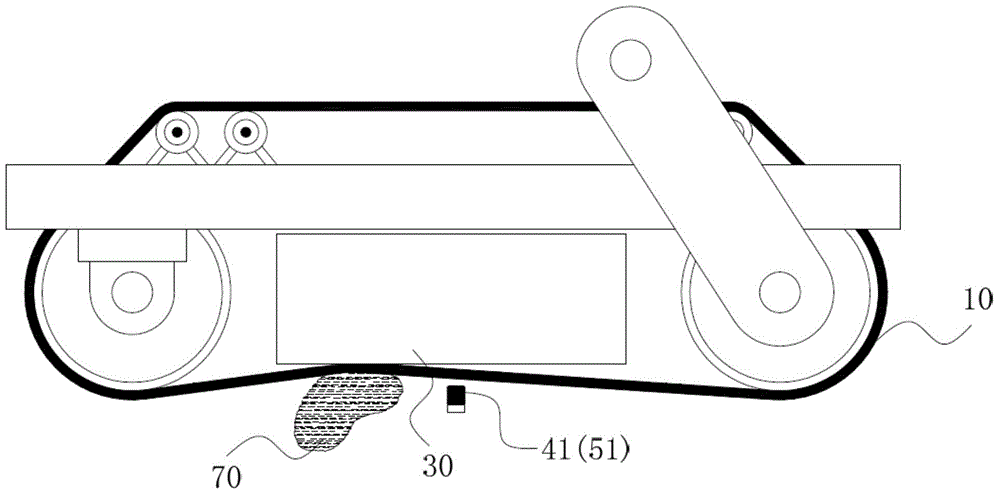

[0024] figure 1 It is the first preferred embodiment of the iron remover with automatic unloading function of the present invention; figure 2 yes figure 1 left view of image 3 yes figure 1 Schematic diagram of the working state of the iron remover in ; Figure 4 yes image 3 left view of . combine figure 1 , figure 2 , image 3 and Figure 4 As shown, the iron remover with automatic iron removal function provided by the present invention includes an iron removal tape 10, a drive motor 20, a magnet 30, sensin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com