Combination die for machining filter casing assembly block

A combination mold and assembly block technology, which is applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of easy rusting of weld seams, high scrap rate, and reducing the welding strength of shells and nuts, so as to increase the service life, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

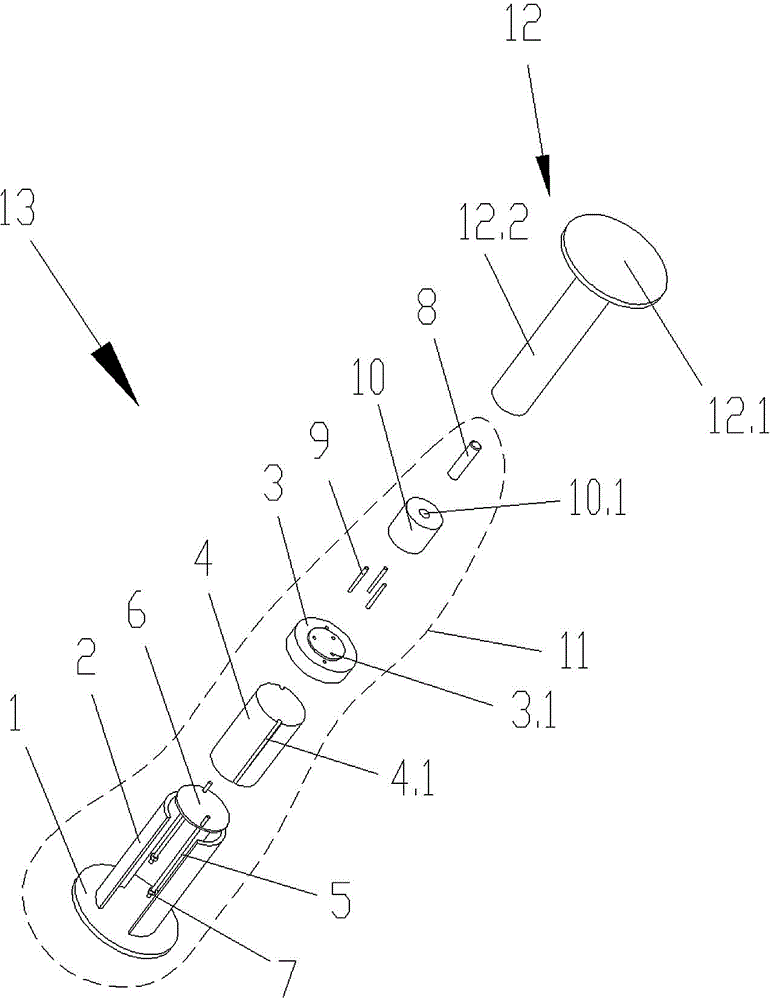

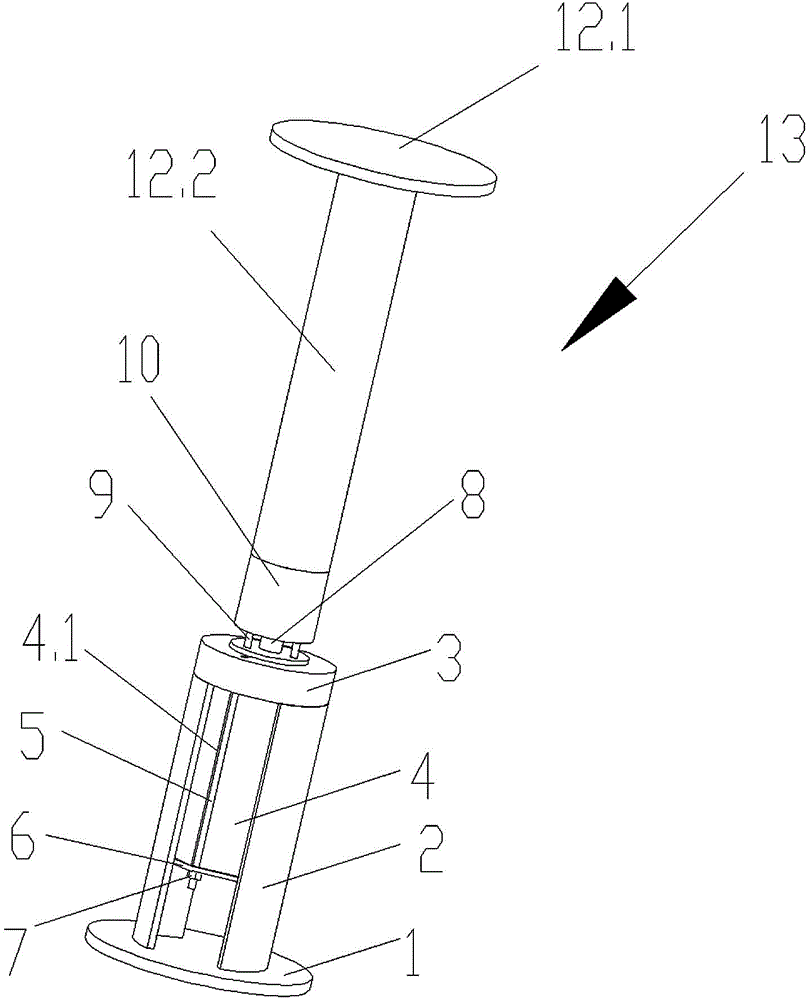

[0030] The present invention provides a composite mold for processing filter shell assembly blocks, the composite mold includes a reverse mold 13 , a pre-stretching mold 14 and a forming mold 15 .

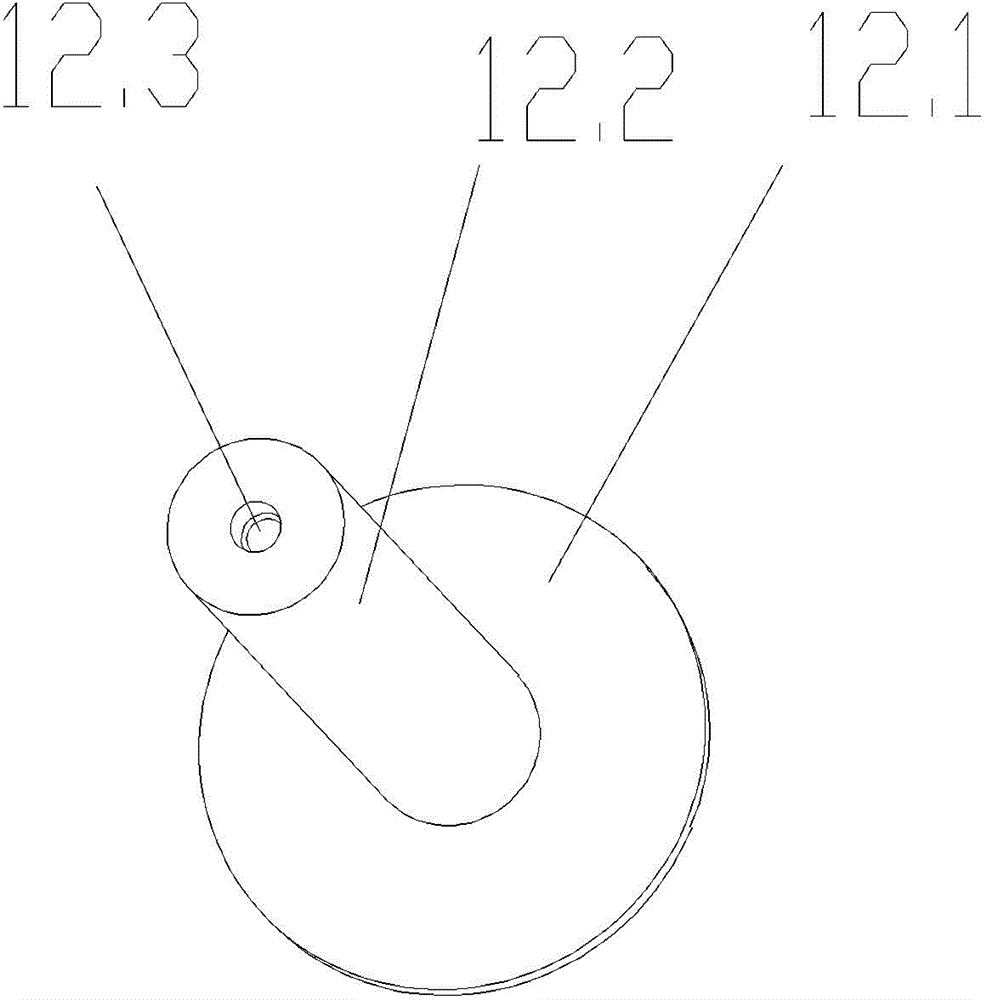

[0031] Such as figure 1 , figure 2 with image 3 As shown, the counter mold 13 includes a first lower mold 11 and a first upper mold 12 that cooperate with each other.

[0032] The first lower mold 11 includes a first lower bottom plate 1 of a disc-shaped structure, two vertical plates 2 are welded on the upper side of the first lower bottom plate 1, and the two vertical plates 2 are arranged symmet...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap