Distributed type electric ducted fan flap lifting system and hovercar thereof

A ducted fan and flying car technology, applied in the field of flying cars, can solve the problems of the propeller without ducted ring protection, the propeller slip flow with slip flow twist, and the unfavorable power increase, so as to achieve a significant lift increase effect and a slip flow. Low speed, low impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

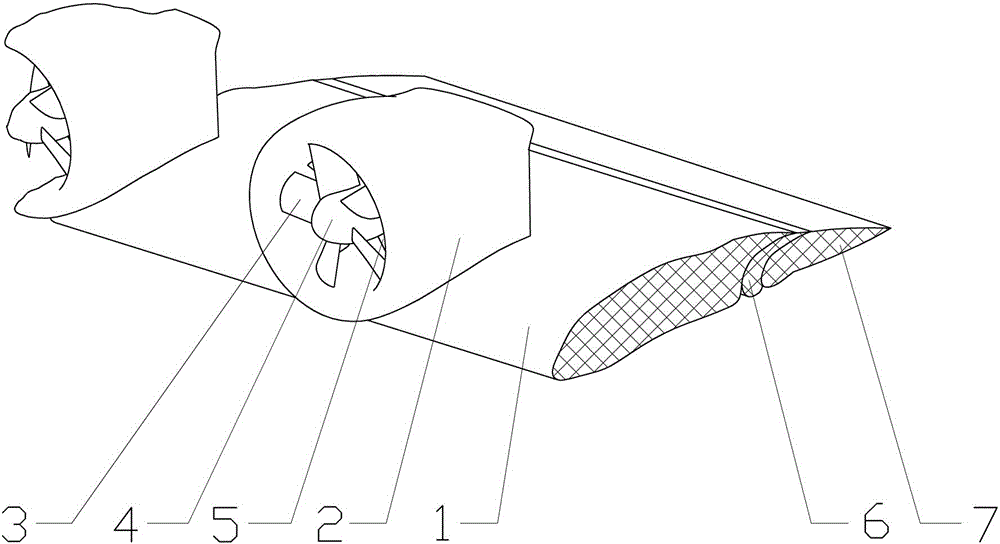

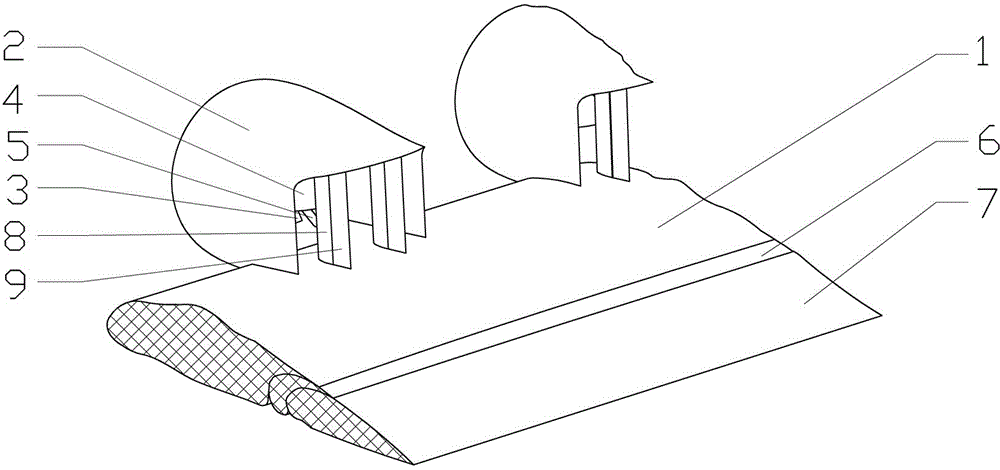

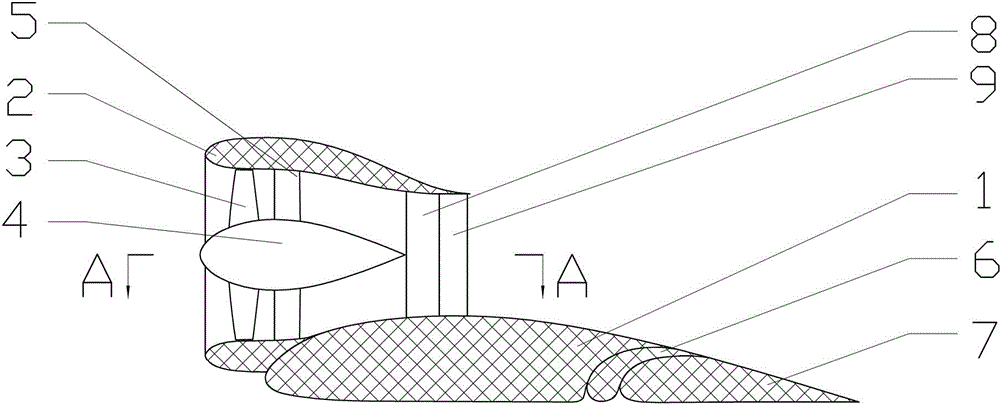

[0027] Such as figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, and 11, the distributed electric ducted fan flap lift system of the present invention comprises a wing 1 and a culvert arranged on the leading edge of the wing 1 The duct fan, the duct fan includes duct 2, the fan 3 in the duct 2, the motor 4 driving the fan 3, the support plate 5 supporting the motor 4, the wing 1 has a trailing edge flap, and there are several duct fans, The leading edge of the wing 1 is linearly arranged at intervals of a certain distance; the leading edge of the duct 2 protrudes in front of the leading edge of the wing 1, and the trailing edge of the duct 2 is located at the position of the maximum thickness of the wing 1. The rear edge of the wing 1 corresponding to where the fan is located is provided with a trailing edge flap.

[0028] Due to the use of electric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com