Multifunctional sewage or wastewater treatment equipment

A wastewater treatment, multi-functional technology, applied in heating water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of low work efficiency, high investment, large land occupation, etc. Achieve the effect of low manufacturing complexity factor, simple equipment structure and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

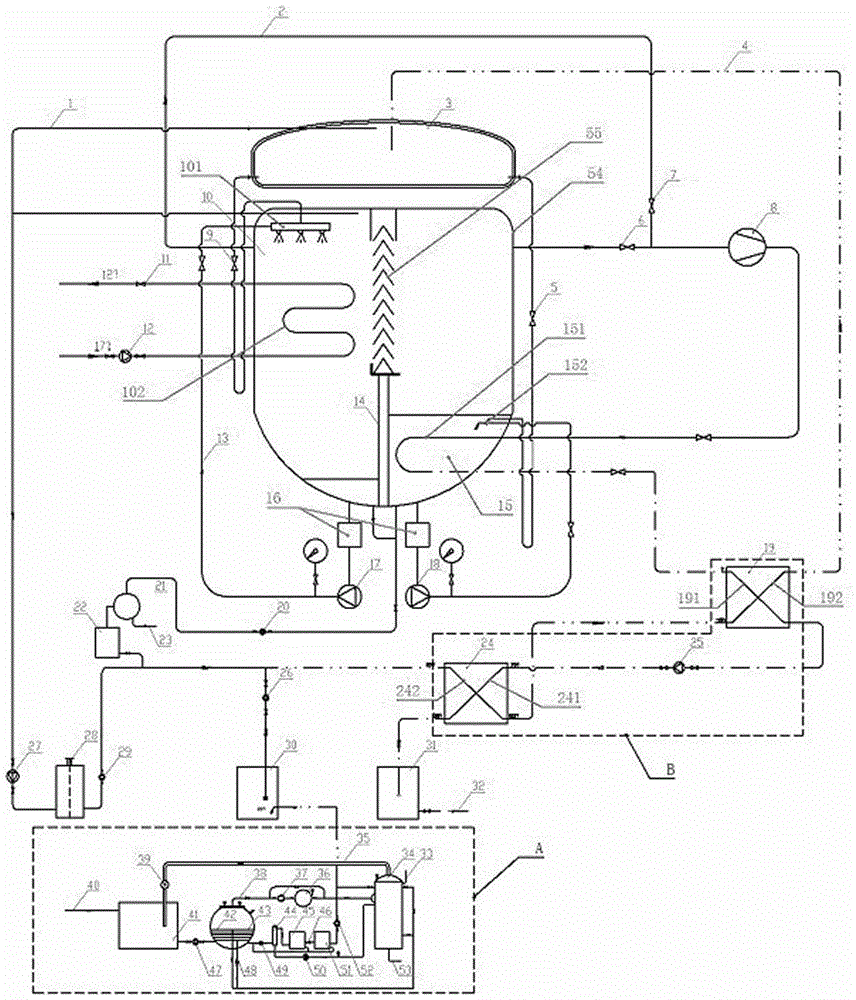

[0009] see figure 1 , a kind of multifunctional sewage or waste water treatment equipment of the present invention, comprises pretreatment unit A, sewage preheating unit B and MVR heat pump unit, and pretreatment unit A unit sends the pretreated sewage after preheating through sewage preheating unit B into the MVR heat pump unit ( figure 1 In addition to the pretreatment unit A and sewage preheating unit B), the MVR heat pump unit evaporates and concentrates the sewage into clean water that meets discharge standards or drinking standards. The pretreatment unit A is located underground. The sewage preheating unit B and the MVR heat pump unit can be installed on a base to form an integrated device.

[0010] Described pretreatment unit A comprises: community centralized septic tank 41, biogas fermentation tank 43, solid / liquid separator 44, pH adjustment tank 45, sewage tank 51 and incinerator 34, the sewage collected by community centralized septic tank 41 Sent to the biogas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com