Rapid beam-replacing construction method for high speed railway 900 t concrete box beam

A technology of concrete box girders and construction methods, applied in bridges, bridge maintenance, bridge reinforcement, etc., can solve many technically difficult problems, and achieve the effect of good adaptability and low comprehensive cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

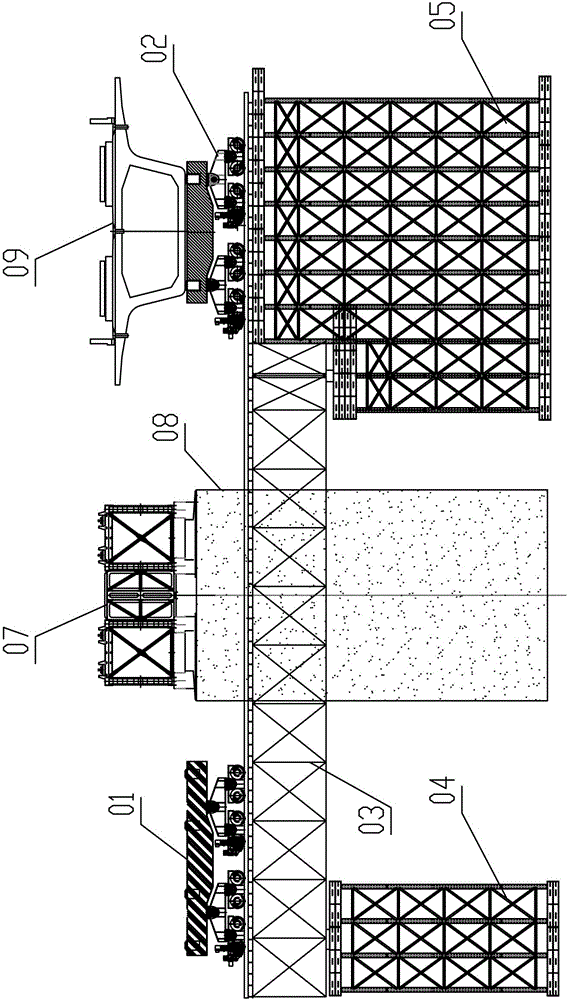

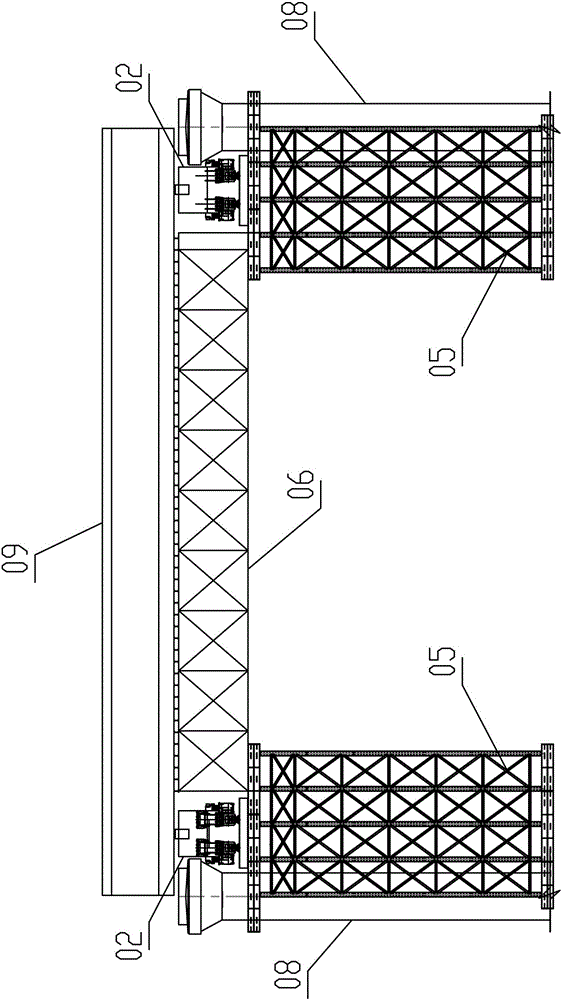

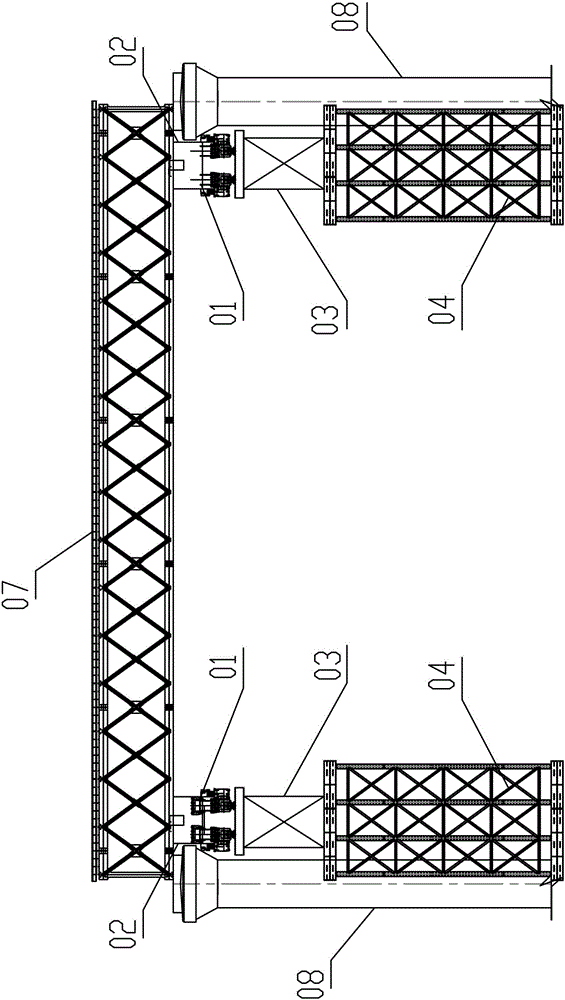

[0029] Attached below Figure 1-7 The invention is described in further detail with specific embodiments:

[0030] as attached Figure 1-7 A quick-change construction method for a 900t concrete box girder of a high-speed railway shown, which includes the following construction steps:

[0031] Step 1: Carry out the installation and layout of the construction structure and equipment for on-site replacement;

[0032] The support structure of the cast-in-place concrete box girder 09 is set up on the site where the side position of the temporary repair steel beam 07 of the frame hole to be changed is parallel to the longitudinal axis of the bridge; Two cast-in-place beam side buttresses 05 and cast-in-place beam support beam crossbeams 06 erected on the two cast-in-place beam side buttresses 05;

[0033] Set up two trestle beams 03 that cross the left and right sides of the bridge hole vertically to the longitudinal axis of the bridge hole and close to the inner side of the brid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com