Soil nailing wall supporting construction method based on assembly type recoverable process

A construction method, the technology of soil nailing walls, applied in basic structure engineering, excavation, construction, etc., can solve problems affecting the development of underground space, geological environmental pollution, and materials that cannot be recycled, and achieve simple and convenient support methods and enhanced structural strength , the effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0047] A construction method based on prefabricated recyclable technology soil nailing wall support, comprising the following steps:

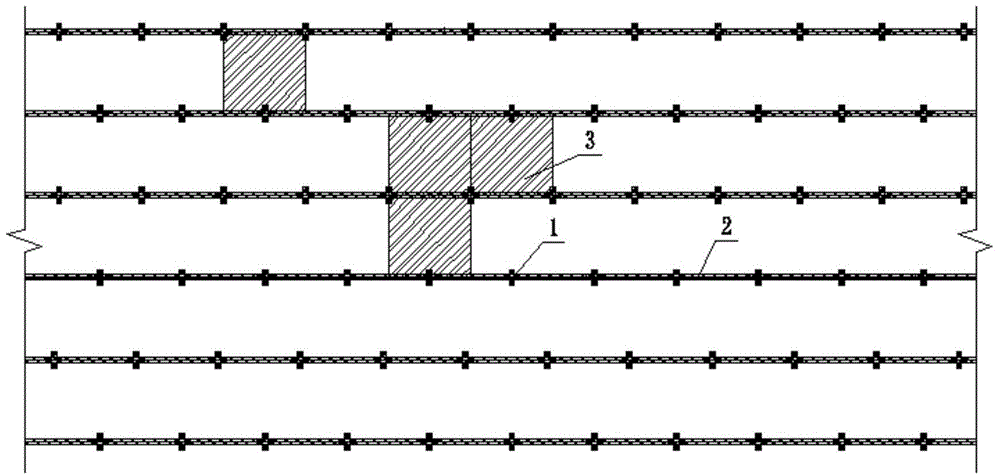

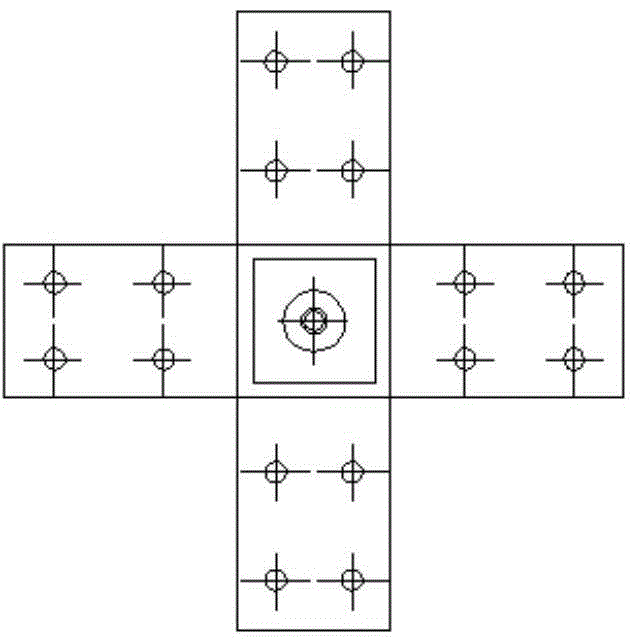

[0048] (1) by arranging a plurality of nodes 6 in the form of a plurality of straight lines on the slope surface, setting soil nails 5 on the nodes 6, setting keels 2 between adjacent nodes 6, and installing panels 3 between the plurality of straight lines, The foundation pit is excavated layer by layer to the bottom of the pit, and multiple nodes, soil nails, keels and panels are set layer by layer to complete the construction of the prefabricated soil nail wall support;

[0049] (2) Dismantling and recycling of supporting materials.

[0050] The specific steps of the support of the prefabricated soil nail wall described in step (1) are as follows:

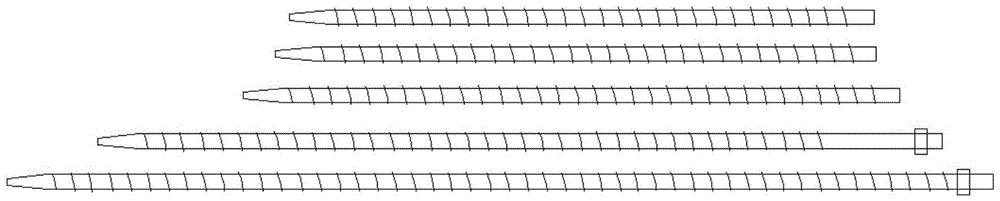

[0051] (1-1) Select corresponding soil nails 5 according to the desi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com