Toilet bowl discharge pipeline

A toilet and pipeline technology, which is applied in flushing toilets, water supply devices, buildings, etc., can solve the problems of poor flushing effect and the amount of flushing water cannot be excessively reduced, and achieve the effect of water saving, reducing and reducing the water consumption for flushing. The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

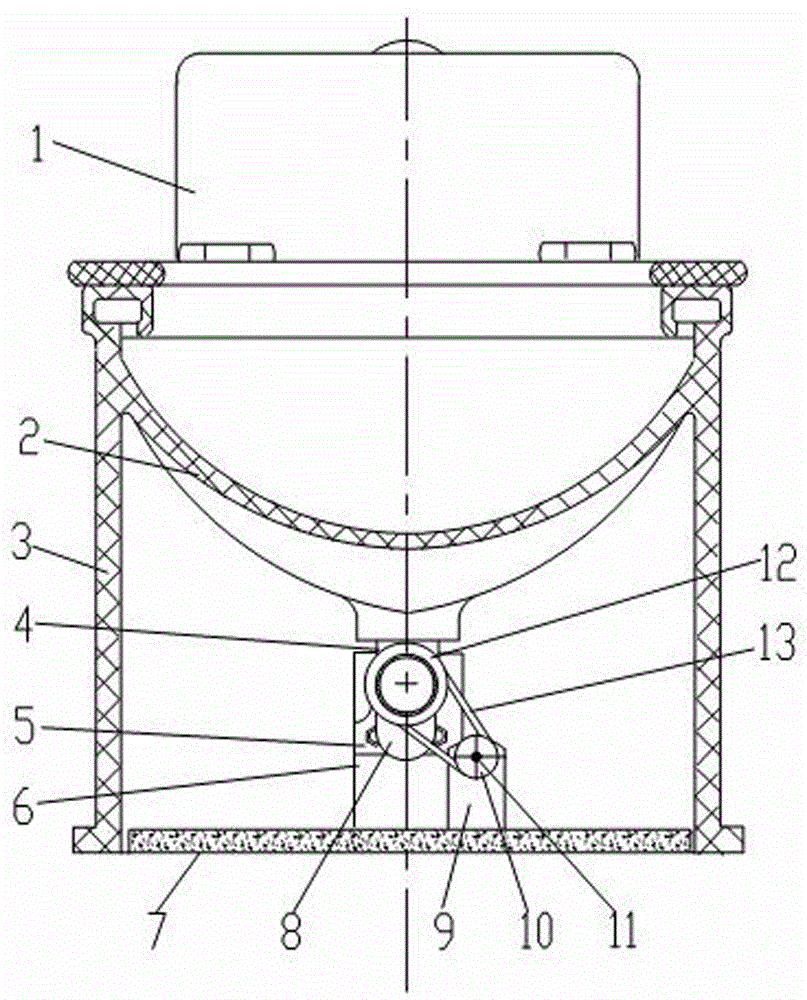

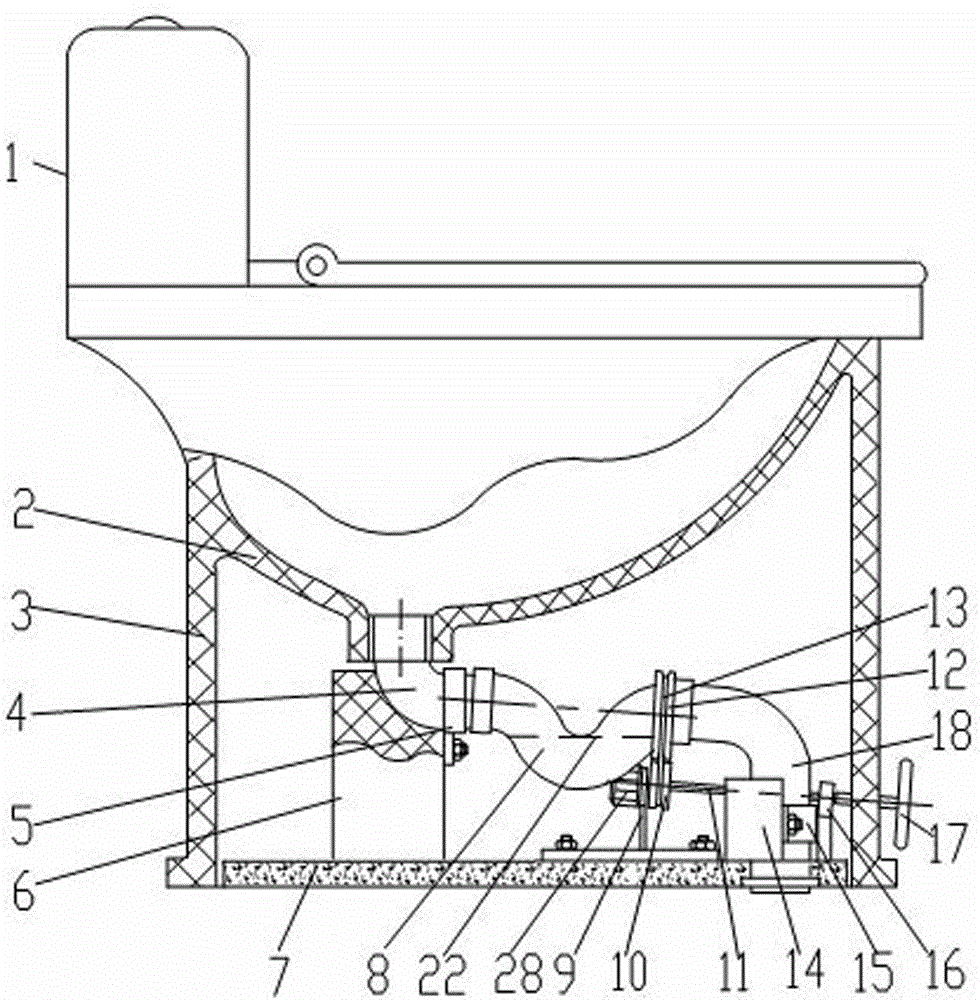

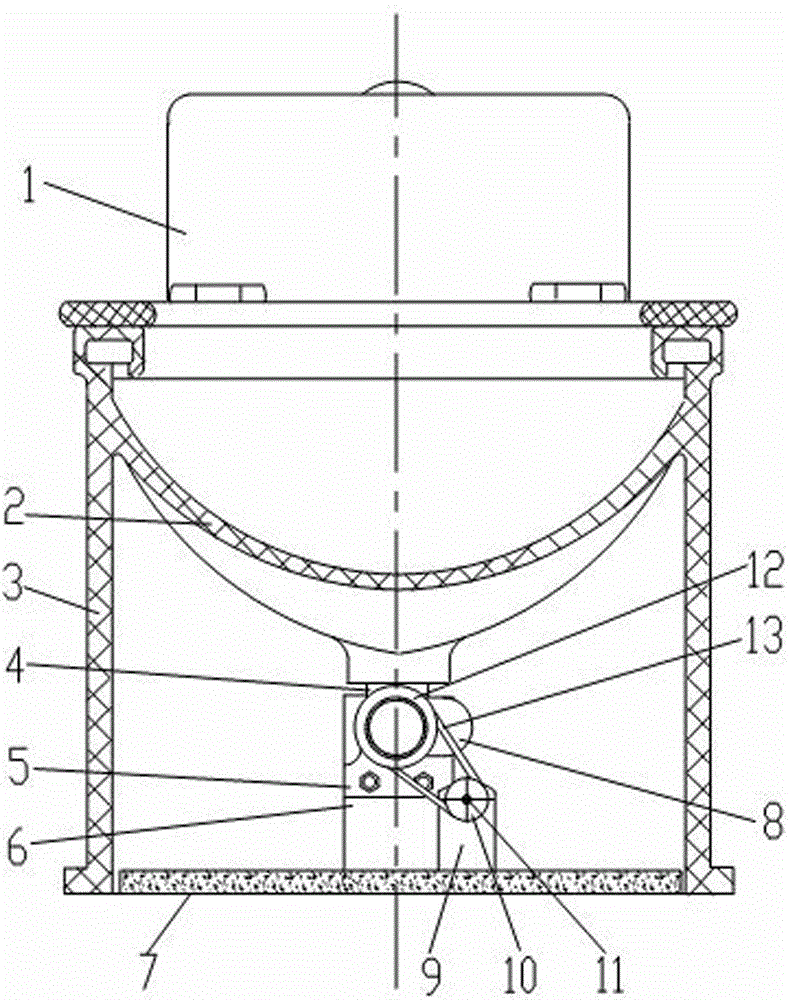

[0023] Embodiment 1: (see figure 1 , 2 , 3, 4) A toilet drainage pipeline, including a flushing elbow 4, a water seal elbow 8 and a discharge elbow 18; the water inlet of the flushing elbow 4 and the bottom drain of the toilet bowl 2 The holes are connected, and the outlet of the discharge elbow 18 is connected with the sewer, and the center of the water outlet of the flushing elbow 4 is higher than the center of the water inlet of the discharge elbow 18; One end is connected with the water outlet set of the flushing elbow 4 , and the other end of the water seal elbow 8 is connected with the water inlet set of the discharge elbow 18 .

[0024] How to use: After going to the toilet, push the water seal elbow 8 to swing it by hand. Since the center of the water outlet of the flushing elbow 4 is higher than the center of the water inlet of the discharge elbow 18, the dirt will self-discharge, and the water will be reversed after flushing. Swing the water seal elbow 8 to make it...

Embodiment 2

[0025] Embodiment 2: (see figure 1 , 2 , 3, 4) The difference between this embodiment and the embodiment 1 is that the drainage pipe of the toilet is also provided with a swing device for controlling the water-sealed elbow 8 . The swing device is a transmission wheel mechanism, and the transmission wheel mechanism includes a base 7, a shaft frame 9, a vertical plate 16, a wheel shaft 11, a driving wheel 10, a driven wheel 12 and a hand wheel 17; 2. On the floor in the vertical tube 3 of the periphery, the first upright pile 6 for fixing the flushing elbow 4 and the second upright pile 14 for fixing the discharge elbow 18 are arranged on the base 7; the shaft frame 9 and the upright The plate 16 is fixed on the base 7, the axle 11 is erected on the shaft frame 9 and the vertical plate 16), the driving wheel 10 is installed on the axle 11, and the driven wheel 12 is installed on the end of the water seal elbow 8 , The driving wheel 10 is connected with the driven wheel 12 thro...

Embodiment 3

[0027] Embodiment 3: (see figure 1 , 2 , 3, 4) The difference between this embodiment and embodiment 2 is: the transmission wheel mechanism further includes a motor 28 , and the motor 28 drives the wheel shaft 11 .

[0028] How to use: install the switch of the motor 28 adjacent to the key switch of the water tank 1, start the motor 28 first after going to the toilet, the driving wheel 10 drives the driven wheel 12 to rotate, the water-sealed elbow 8 swings to make the dirt self-discharge, rinse with water Motor 28 is reversed, and water seal elbow 8 gets back to the original position to store water and form a water seal. The handwheel 17 can be used during a power outage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com