Multi-stage mechanical seal type roadheader internal spray rotary water seal device

A technology of mechanical seals and sealing devices, which is applied in cutting machinery, earthwork drilling and mining, etc., can solve problems such as nozzle clogging, unpredictable life, no insurance and early warning functions, etc., and achieves enlarged working area and reliable axial movement , to achieve the effect of axial movement adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

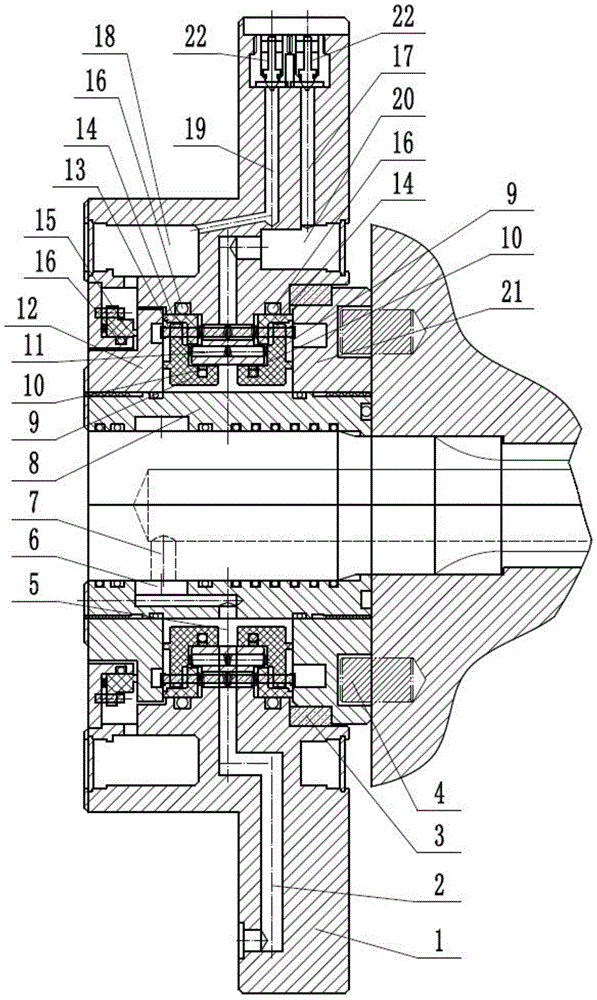

[0032]As shown in the figure, the spray rotary water sealing device in the multi-stage mechanical seal roadheader is characterized by: including the shell 1, the water channel 2, the dustproof ring 3, the driving pin 4, the primary chamber 5, and the ring groove of the spacer 6. Spindle water channel 7, spacer sleeve 8, first-stage static ring 9, gray ring 10, spring 11, synchronous turntable 12, positioning pin 13, second-stage static ring 14, third-stage static ring 15, o-ring 16, second Primary chamber oil passage 17, third-stage chamber oil storage chamber 18, third-stage chamber oil passage 19, secondary chamber oil storage chamber 20, driven turntable 21, pressure relief valve 22, the water passage 2 is located in the housing 1, the water channel 2 is fixedly connected to the primary chamber 5; the spacer ring groove 6 is fixedly connected to the primary chamber 5 through a pipe; one end of the main shaft water channel 7 is fixedly connected to the spacer ring groove 6, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com