A coal shearer automatic cutting system and method based on infrared thermal imaging

A technology of infrared thermal imaging and infrared thermal imaging, which is applied in the direction of earthwork drilling and cutting machinery, etc., can solve the problem that the intelligent algorithm cannot accurately identify, cannot accurately identify the shearer, and the identification result of the cutting state is incorrect. The results of automatic identification of coal-rock interface are comprehensive, the signal is easy to pick up, and frequent adjustments are avoided.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

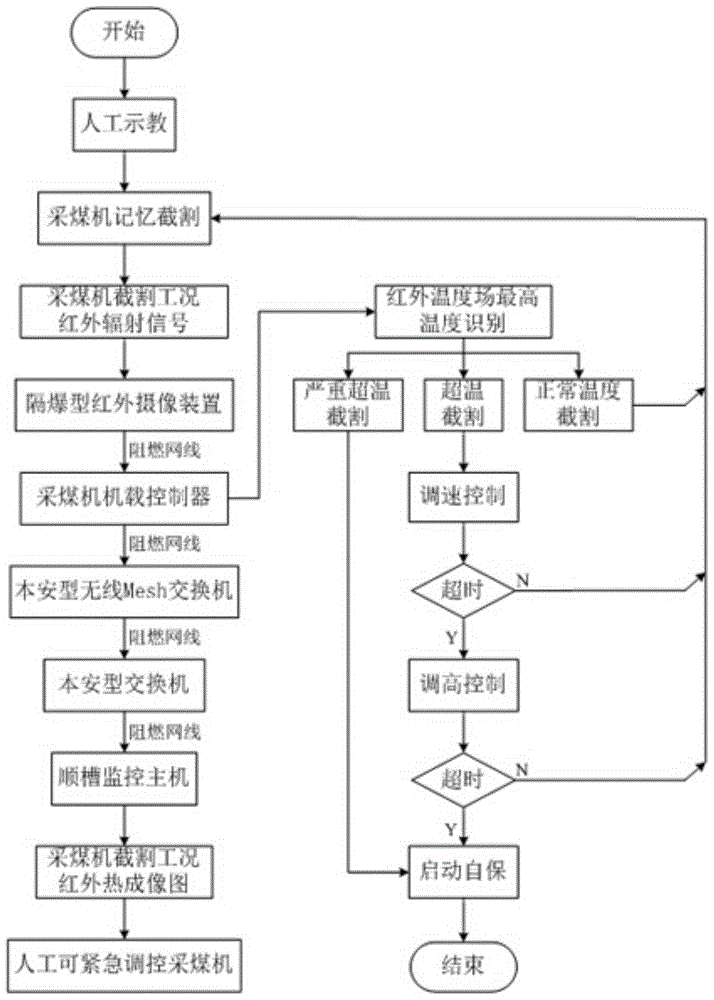

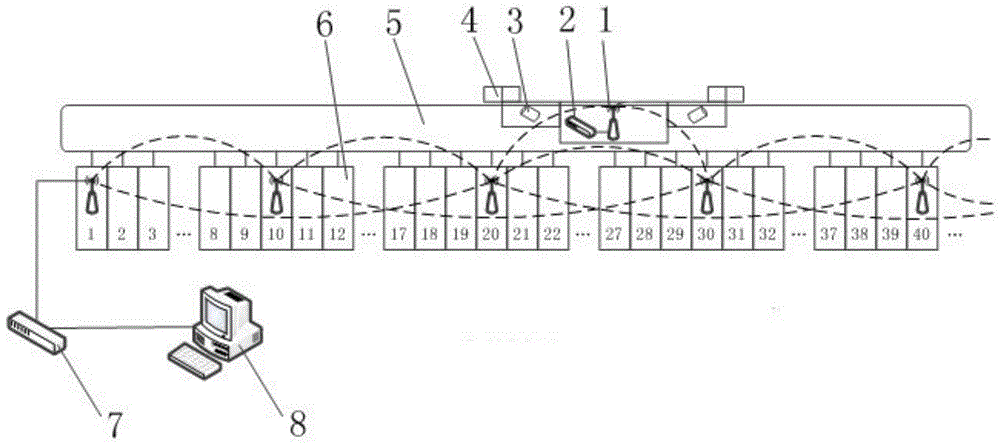

[0026] The present invention will be further described below in conjunction with accompanying drawing.

[0027] Such as figure 1 , figure 2 As shown, an automatic shearer cutting system based on infrared thermal imaging includes a shearer 4, a scraper conveyor 5, a hydraulic support 6, an intrinsically safe wireless Mesh switch 1, and an airborne controller 2 for the shearer , Intrinsically safe switch 7, along the trough monitoring host 8, the shearer 4 is used in conjunction with the scraper conveyor 5 and the hydraulic support 6, and the running mechanism of the shearer 4 is matched with the scraper conveyor 5;

[0028] It also includes an explosion-proof infrared camera device 3, which is arranged on the rocker arm of the shearer 4, and is connected with the on-board controller 2 of the shearer through a flame-retardant network cable, and the shearer machine The load controller 2 is connected to the intrinsically safe wireless Mesh switch 1 through a flame-retardant net...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com