Electrically operated valve

A technology of electric valve and valve seat, which is applied in the direction of valve lift, valve device, valve details, etc. It can solve the problems of complex configuration and structure of rectification components, reduction of refrigerant flow loss, etc., and achieves reduction of abnormal sound and simple configuration structure , the effect of suppressing flow loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

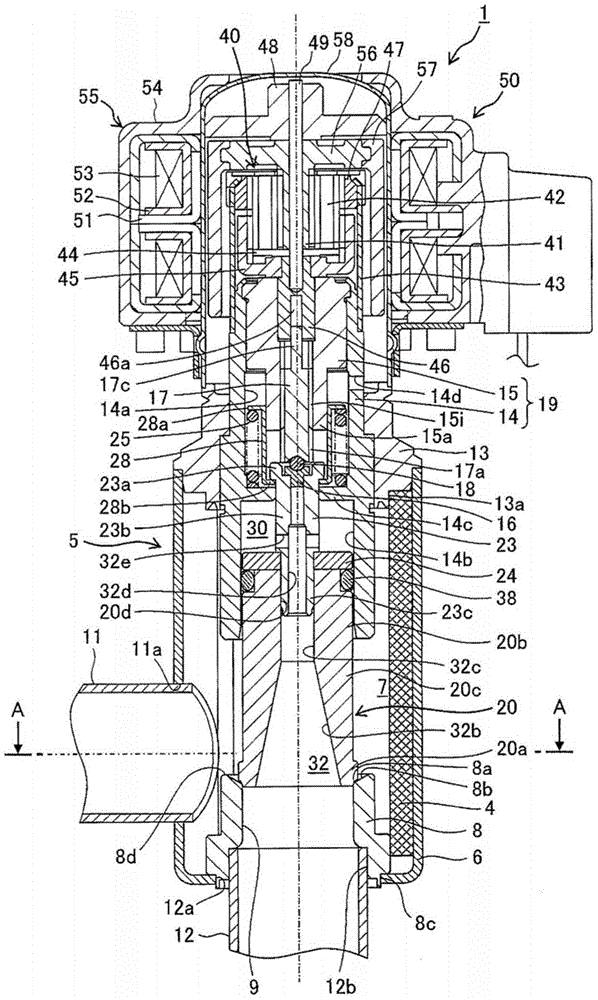

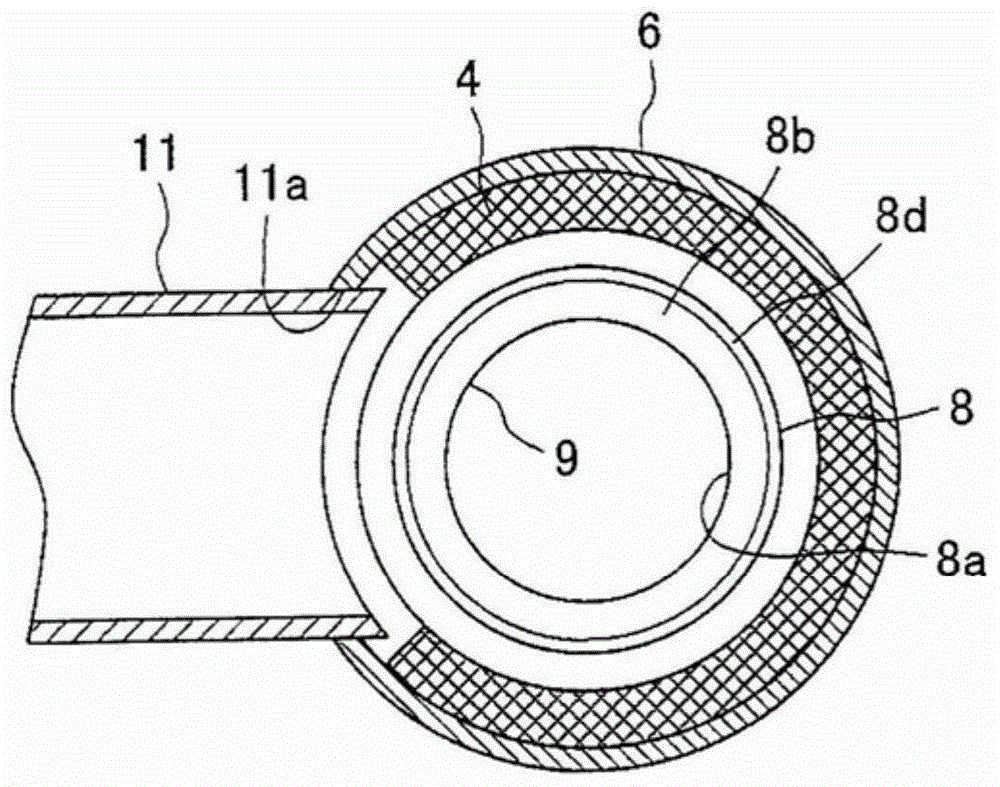

[0066] figure 1 It is a longitudinal sectional view of the first embodiment of the electric valve of the present invention, figure 2 yes figure 1 A-A in the cross-sectional view. In addition, in figure 2 In, the spool is omitted to represent.

[0067] The electric valve 1 shown in the figure is a two-way flow electric valve: it is used as an expansion valve in heat pump refrigeration and heating systems, etc., and the fluid (refrigerant) flows in two directions (the first flow direction and the second flow direction opposite to it). Flow direction) flow, and at least one direction corresponds to a flow channel with a large flow rate.

[0068] The electric valve 1 mainly has: a valve main body 5, which has a cylindrical substrate 6 made of sheet metal; a housing 58, which is fixed on the valve main body 5; a supporting member 19, which is supported by the valve main body. 5 and the internal space divided by the housing 58 is fixed on the valve main body 5; the valve co...

no. 2 Embodiment approach

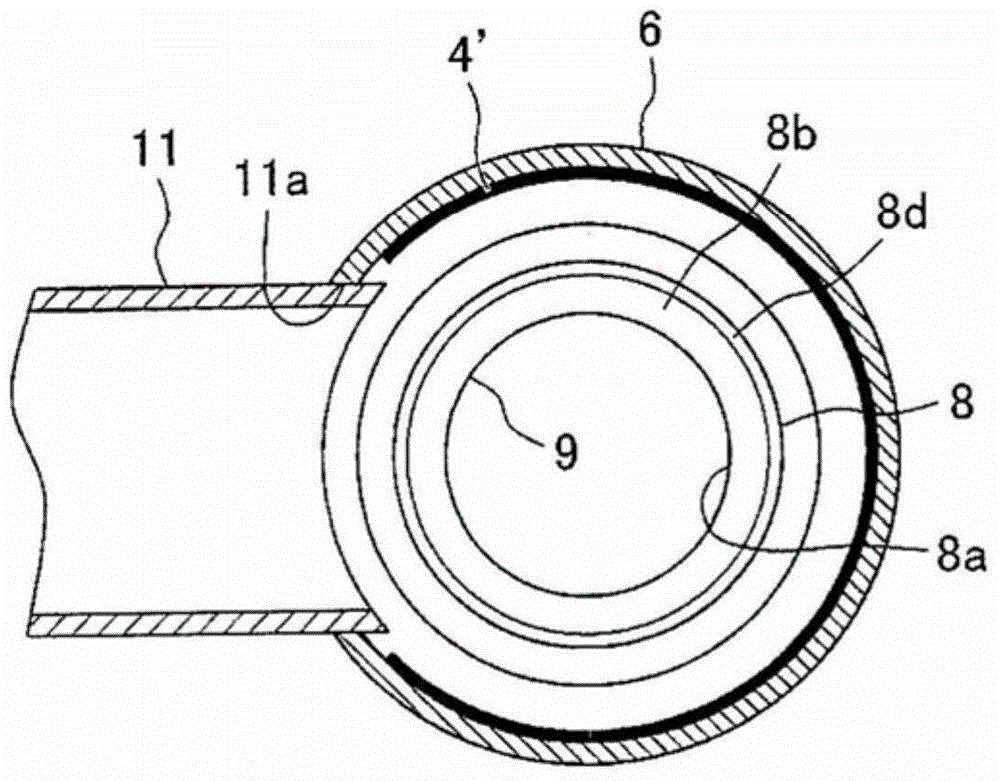

[0091] Figure 4 It is a cross-sectional view showing a second embodiment of the electric valve of the present invention. The electric valve of the second embodiment differs from the electric valve of the above-mentioned first embodiment in the shape of the porous body made of foamed metal, and the other structures are basically the same as those of the electric valve 1 of the first embodiment. Therefore, the same reference numerals are assigned to the same structures as those of the electric valve of the first embodiment, and detailed description thereof will be omitted.

[0092] When the gas refrigerant flows in the second flow direction in a state of excessive gas, it has been confirmed by experiments by the inventors of the present invention that the valve port 9A on the side opposite to the first opening 11aA In the region between the portion and the inner wall surface of the valve main body 5A, the above-mentioned periodic vortex flow is generated in the region close to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com