Corrosion-resistant heat pump type horizontal sleeve heat exchanger

A corrosion-resistant heat exchanger technology, applied in heat exchange equipment, tubular elements, lighting and heating equipment, etc., can solve the problems of reduced efficiency, wide usability constraints, troublesome maintenance, cleaning and disassembly, etc., to improve heat transfer High efficiency, excellent corrosion resistance, no oil storage dead angle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

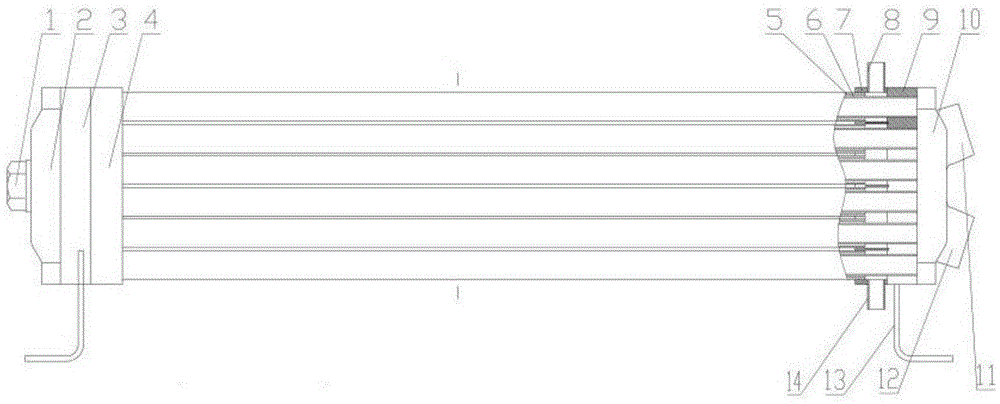

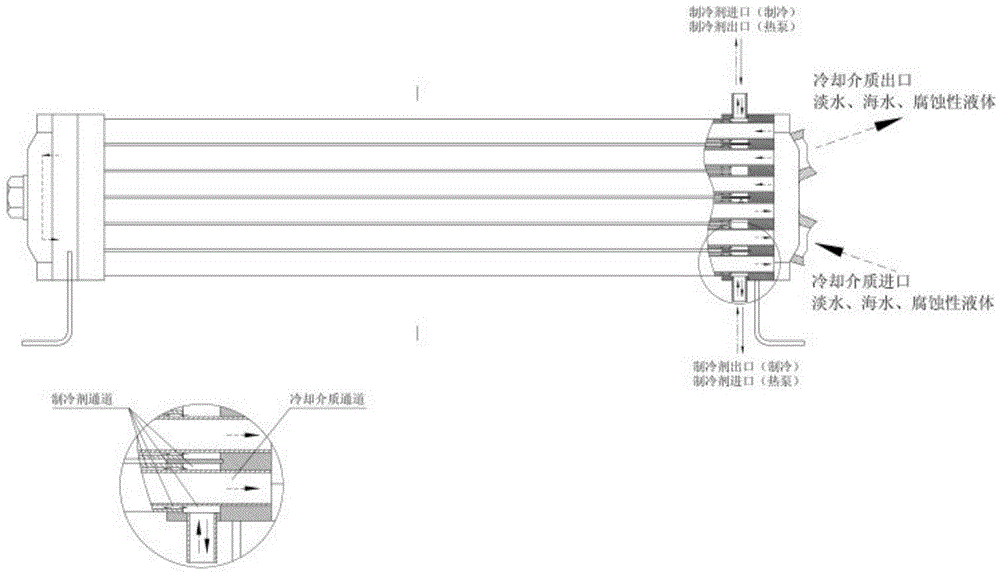

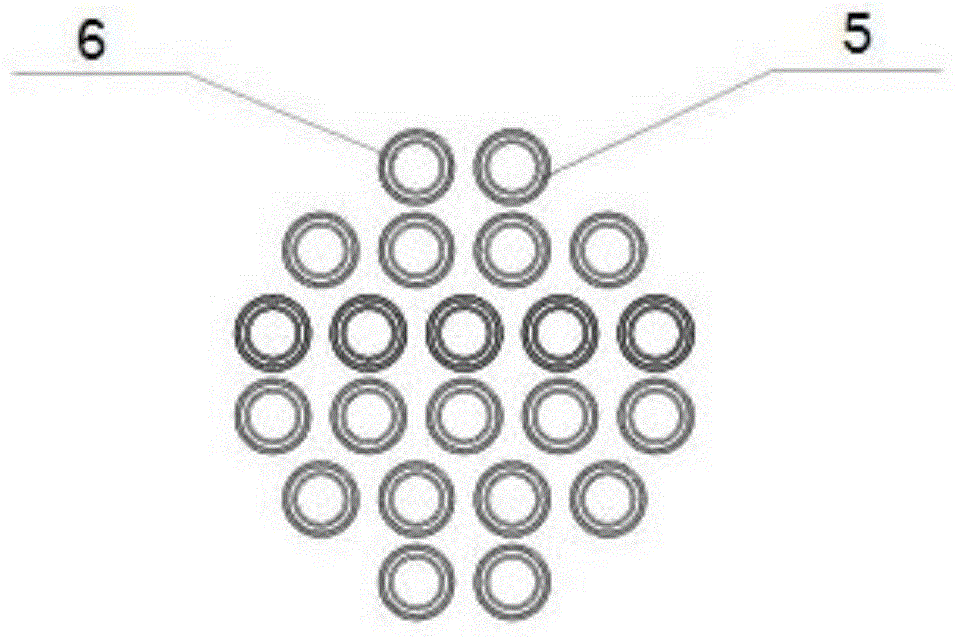

[0018] like figure 1 As shown, the present invention provides a novel corrosion-resistant heat pump type horizontal casing heat exchanger, which adopts a horizontal installation method and is composed of an anticorrosion block 1, a cap, an outer casing tube sheet, a composite tube, and a tube sheet. The cover includes cover I2 and cover II10, the anticorrosion block 1 is fixedly connected with the cover I2, the tube sheet includes the tube sheet I3 and the tube sheet II9, the cover I2 is connected with the tube sheet I3, and the Outer casing tube plate includes outer casing tube plate I4 and outer casing tube plate II7, said tube plate I3 is connected with outer casing tube plate I4, said outer casing tube plate II7 is connected with outer tube plate II9, said tube plate II9 is connected to cover head II10, a refrigerant inlet 8 is provided on one side of the upper end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com