Wideband variable-temperature dielectric constant testing system for solid and powder materials

A powder material and dielectric constant technology, applied in the microwave field, can solve the problems of high requirements, low test accuracy, complicated operation, etc., and achieve the effect of easy calibration, simple operation, and improved test accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

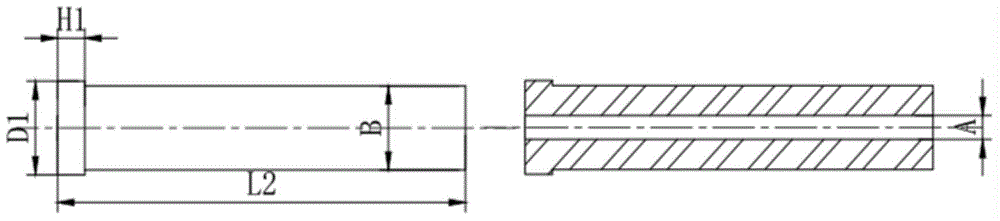

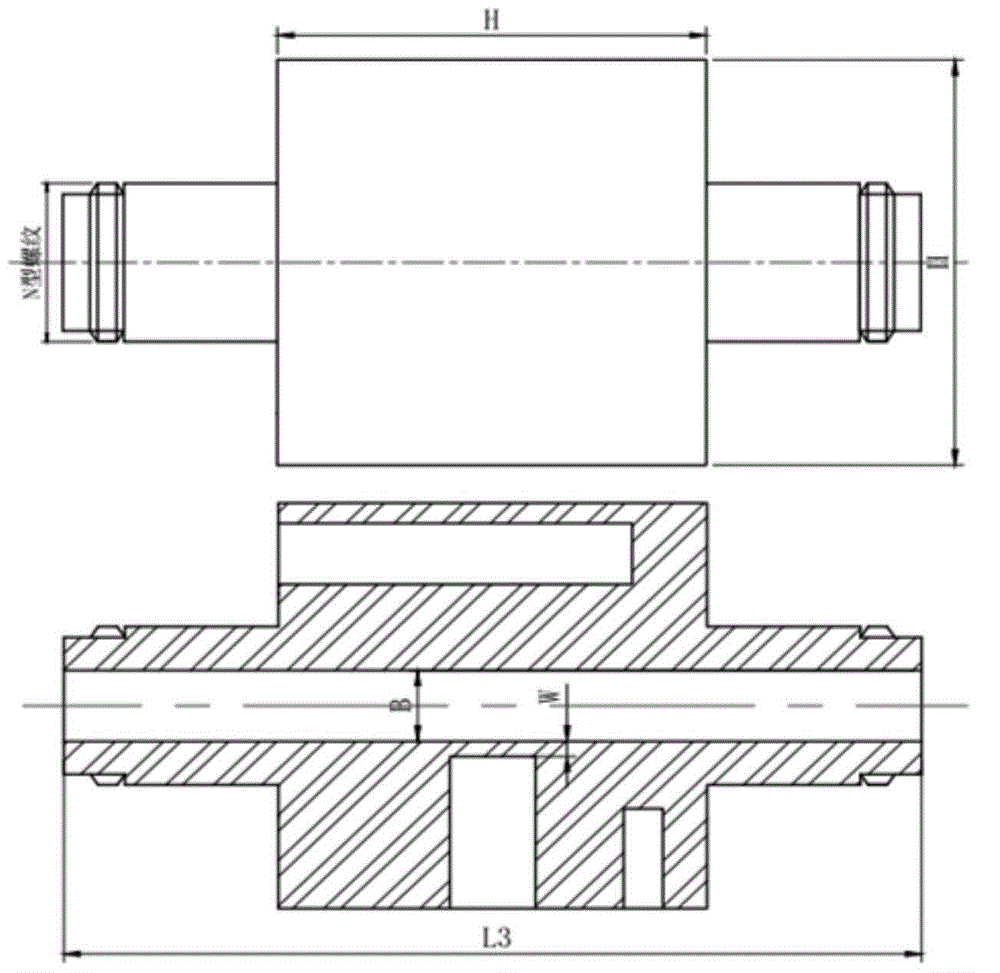

[0039] In this embodiment, the test system designed by the present invention is designed according to the radio frequency 50 ohm impedance matching design, reduces reflection, and is used in conjunction with the microwave measurement system, and has good matching. Secondly, in this embodiment, the connectors of the test system designed by the present invention refer to the N-type radio frequency coaxial connector, and the size of the part where the heating rod and temperature sensor are placed in the middle is HxH. The specific size can be based on the heating rod and Temperature sensor adjustment. The specific design is described in detail below:

[0040] The broadband variable temperature dielectric constant test system for solid and powder materials of the present invention includes:

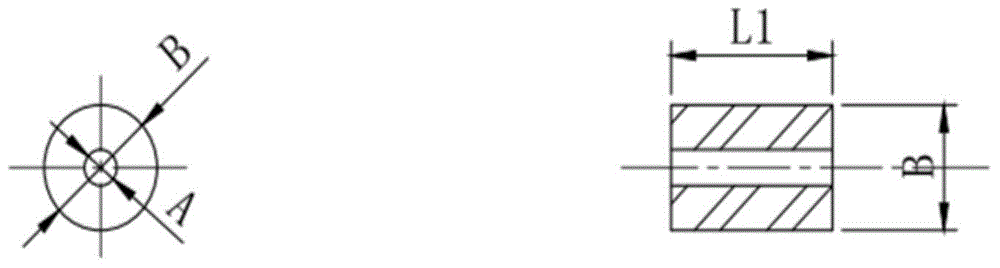

[0041] The measured solid material, such as figure 1 As shown, the inner circle through hole diameter is A=2mm, the outer ring diameter is B=7mm, and the length is L1=10mm.

[0042] Do not process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com