Integrated multi-model method for controlling CSTRs (continuous stirred tank reactors)

A control method and reactor technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve problems such as difficult scheduling, affecting control effect, and system instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

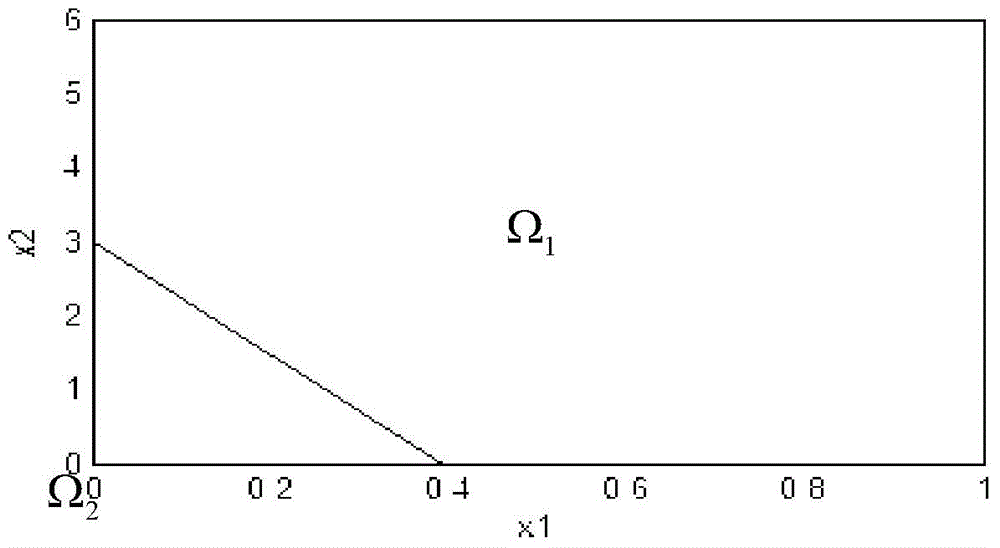

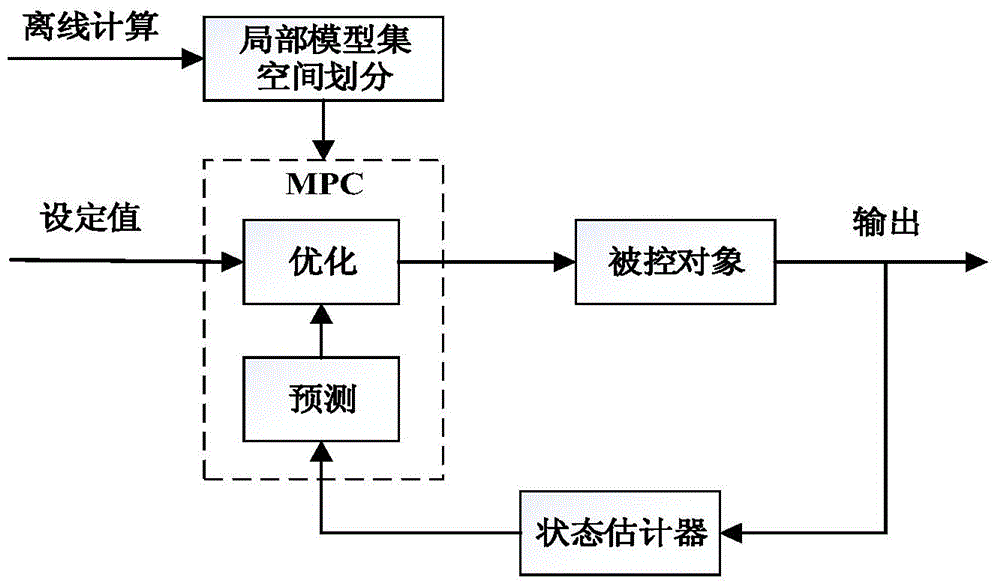

[0059] In order to improve the shortcomings of the traditional multi-model method, the present invention proposes a multi-model method integrating space division and optimization control based on the hybrid system theory, which is not only applicable to the process object of CSTR, but also applicable to general nonlinear system control question. In order to make the object, technical solution and advantages of the present invention clearer, the method is used in the switching process of the first-order reaction CSTR working point in the following. The specific implementation steps are as follows:

[0060] 1. Carry out state space modeling for the first-order reaction CSTR process object, and determine its normal working range, input constraints, steady-state operating point and other information.

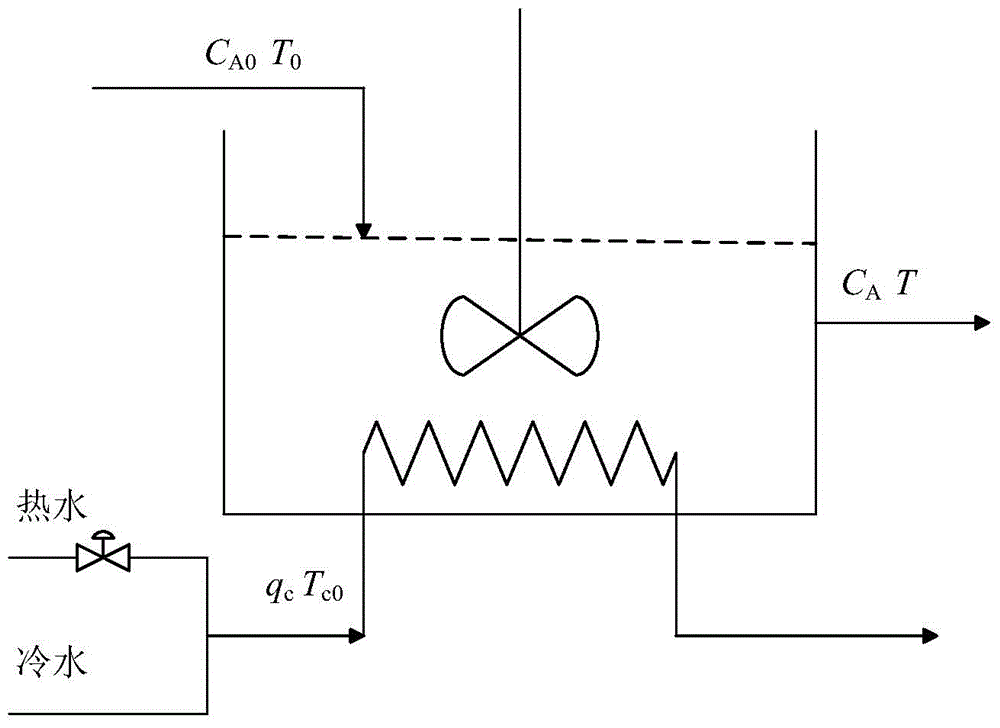

[0061] The CSTR process considered in the present invention has been studied by many scholars as a classical nonlinear object. Such as figure 1 As shown, what is going on in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com