Groove processing tool and scoring device with same

A technology for processing tools and grooves, applied in the field of scribing devices, can solve the problems of deterioration of cutting ability, insufficient insulation effect, narrow processing groove width, etc., and achieve the effect of preventing deterioration of cutting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Hereinafter, the details of the present invention will be described in detail based on drawings showing embodiments thereof.

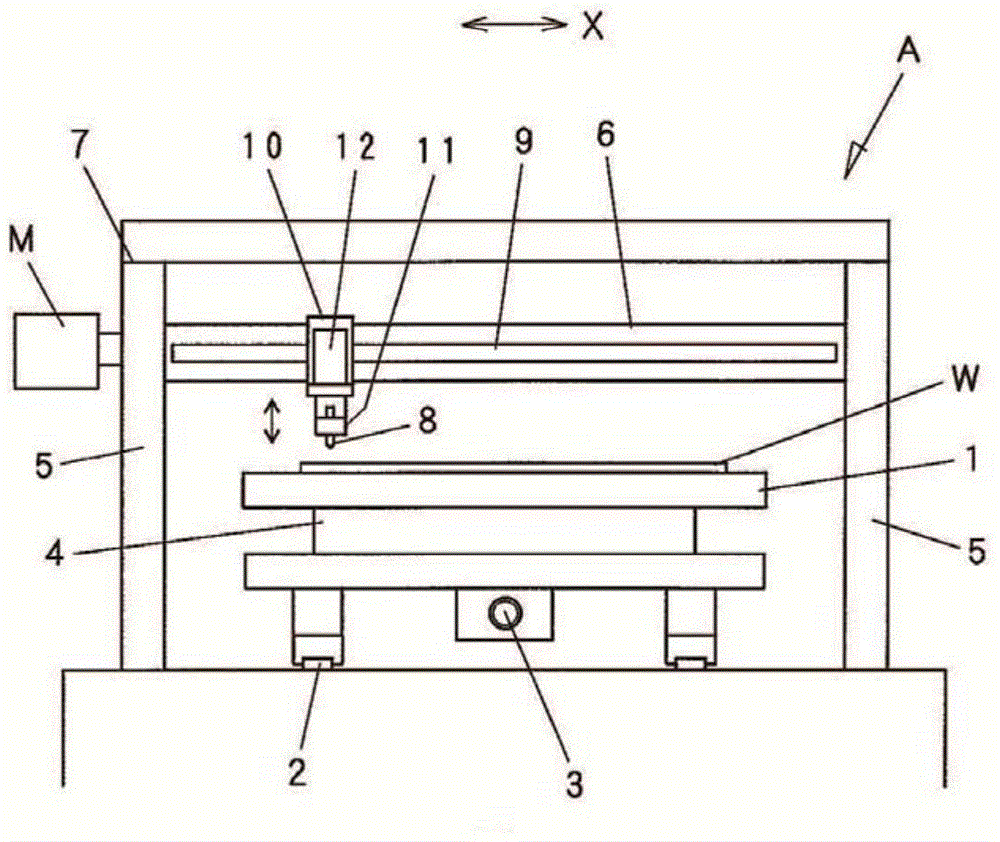

[0044] figure 1 It is a schematic front view showing an example of a scribing apparatus for a build-up type thin-film solar cell using the trenching tool of the present invention.

[0045] The scribing apparatus A includes a table 1 on which a solar cell substrate W is placed and held. The platform 1 becomes able to move along the horizontal rail 2 in the Y direction ( figure 1 front and rear directions) and is driven by a screw shaft 3 that is rotated by a motor (not shown). Furthermore, the platform 1 can be rotated in a horizontal plane by the rotation drive part 4 with a built-in motor.

[0046] A bridge frame 7 including support columns 5 and 5 on both sides provided across the platform 1 and beams (beams) 6 extending horizontally in the X direction is installed so as to straddle the platform 1 .

[0047] The beam 6 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com