Temperature control system of power modular battery

A technology of temperature control system and power module, which is applied in the direction of battery temperature control, battery, secondary battery, etc., can solve the problems such as the complexity of the flow channel structure, and achieve high energy utilization efficiency, good phase change heat storage capacity, Effect of Good Temperature Uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

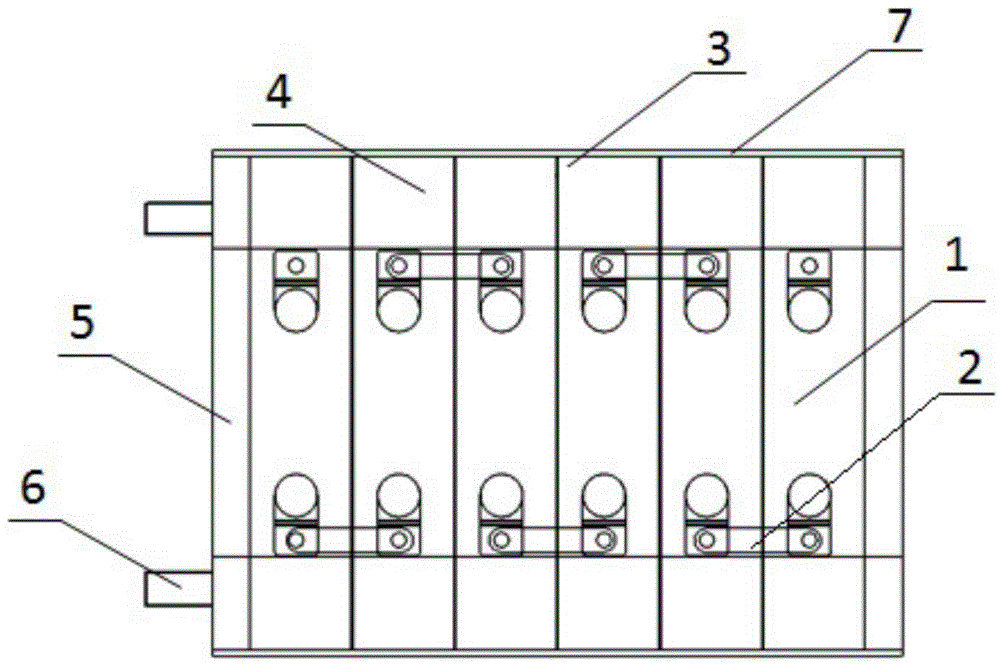

[0034] Such as figure 1 As shown, the system mainly includes the following functional modules:

[0035] A battery cell 1, a battery integrated module 3 composed of a number of battery cells 1 connected through metal connecting pieces 2, a phase change temperature control board 4 in direct contact with the battery, and a temperature control board 4 for improving the temperature between the battery and the phase change temperature control board 4 High thermal conductivity graphite sheet with heat rate, heat exchange fluid pipeline 6 used to accommodate heat exchange fluid, and battery case and fastening device used to accommodate battery integrated module 3 and temperature control components.

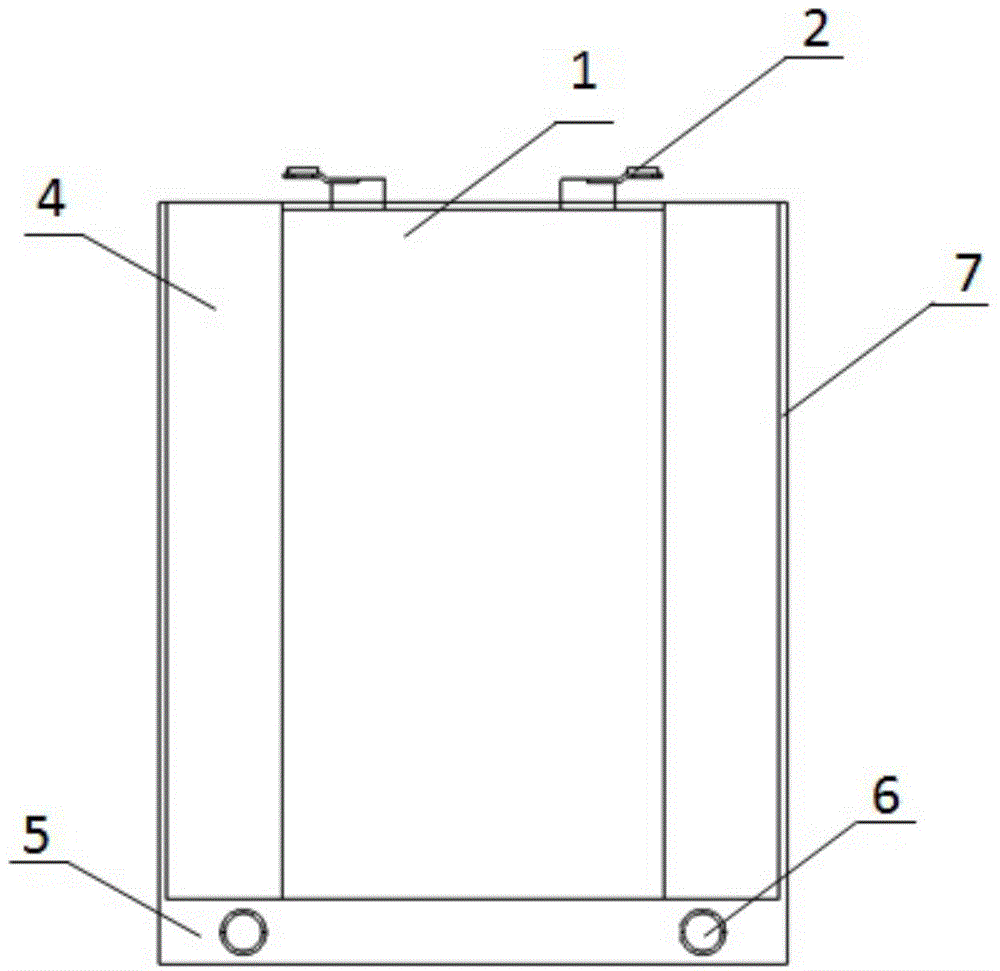

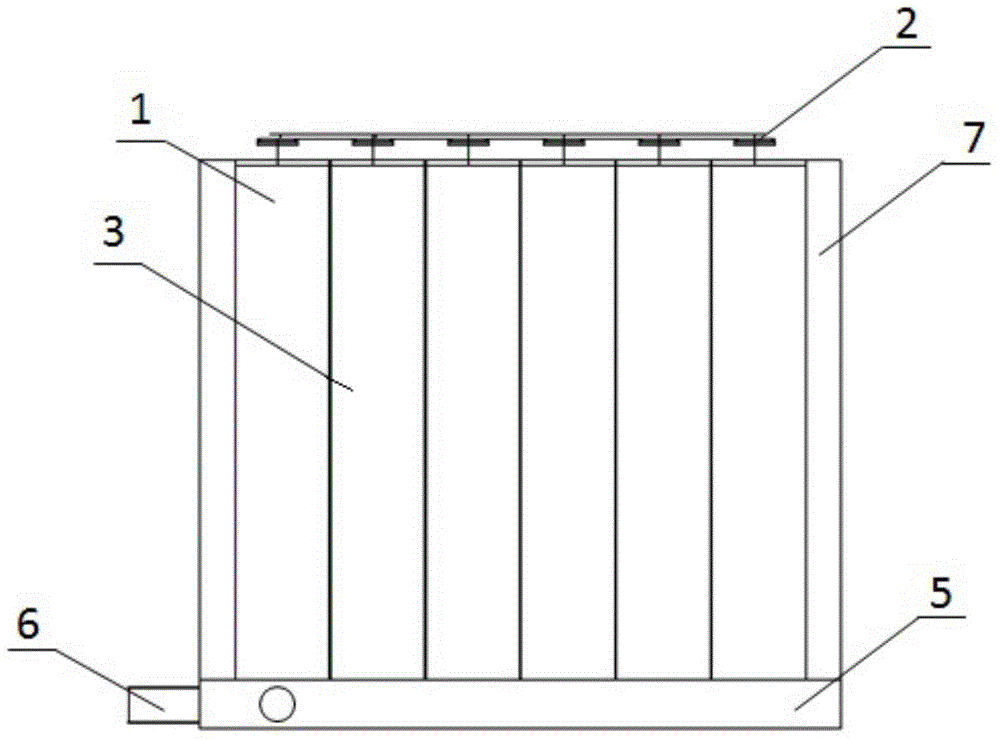

[0036] Such as Figure 2-3 As shown, a battery integrated module 3 composed of several square lithium iron phosphate battery cells 1 connected to the electrodes through metal connecting pieces 2 is placed in the middle position, and the side of the battery cells 1 is arranged with an enh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com