Radial ventilation cooling structure of motor

A technology of cooling structure and radial ventilation, applied in the direction of cooling/ventilation device, magnetic circuit shape/style/structure, electromechanical device, etc., can solve the problems of small air velocity, thermal deformation of iron core support, large maximum temperature value, etc., to achieve Avoid downtime, ensure normal operation, and improve the effect of balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

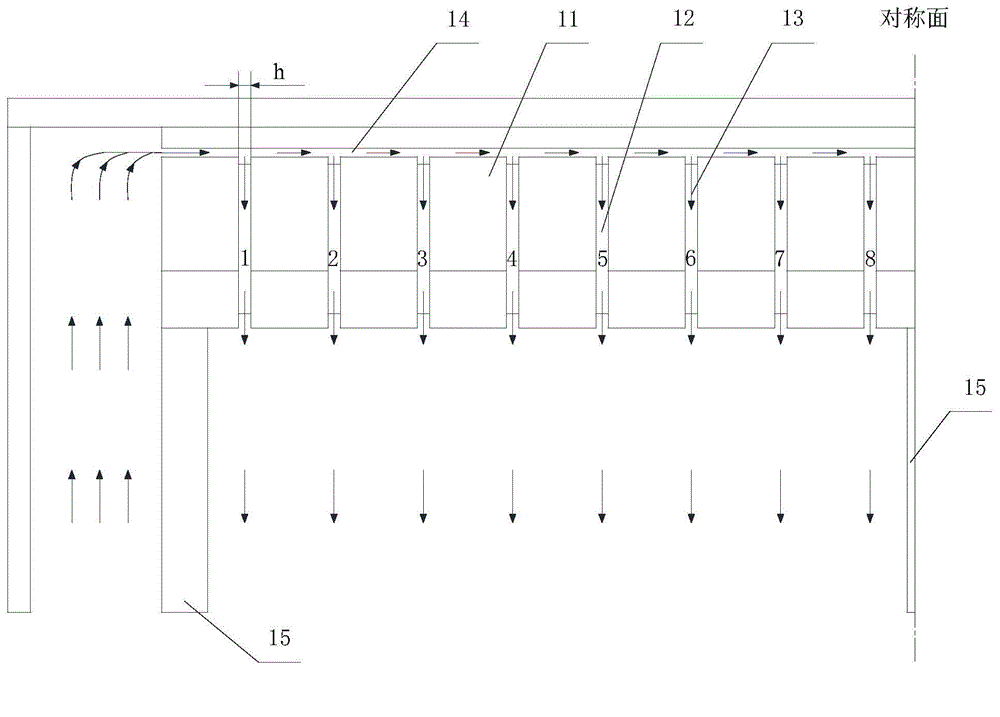

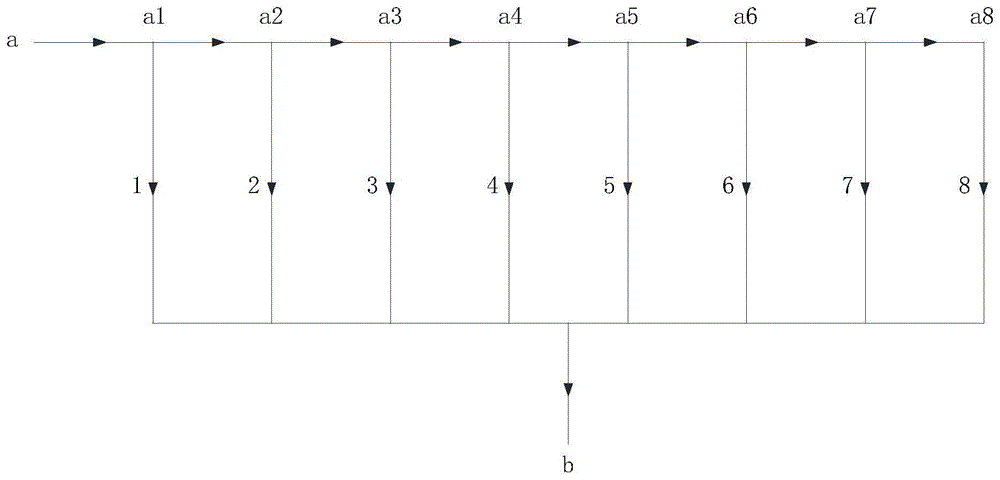

[0038] refer to figure 1 As shown in the existing motor radial ventilation cooling structure, the motor radial ventilation cooling structure of the embodiment of the present invention also includes at least three iron core segments 11, and ventilation channel steel 12 is arranged between adjacent iron core segments 11, adjacent A ventilation groove 13 is formed between the iron core segment 11 and the ventilation channel steel 12, but different from the existing motor radial ventilation cooling structure, due to the different structures of the multiple ventilation channel steels 12 and / or the multiple core segments 11, As a result, the impedance R of the plurality of ventilation grooves 13 gradually increases along the direction from both ends of the motor to the middle of the motor.

[0039] Specifically, the resistance R of the ventilation groove 13 is the resistance of the ventilation groove 13 to the airflow (including local resistance and along-way resistance). The venti...

Embodiment 2

[0045] refer to figure 1 As shown in the existing motor radial ventilation cooling structure, the motor radial ventilation cooling structure of the embodiment of the present invention also includes at least three iron core segments 11, and ventilation channel steel 12 is arranged between adjacent iron core segments 11, adjacent A ventilation groove 13 is formed between the iron core segment 11 and the ventilation channel steel 12, but different from the existing motor radial ventilation cooling structure, due to the different structures of the multiple ventilation channel steels 12 and / or the multiple core segments 11, As a result, the impedance R of the plurality of ventilation grooves 13 gradually increases along the direction from both ends of the motor to the middle of the motor, and the impedance S of the ventilation paths where the plurality of ventilation grooves 13 are located is equal. Wherein, the impedance S of the ventilation path is equal to the sum of the impedan...

Embodiment 3

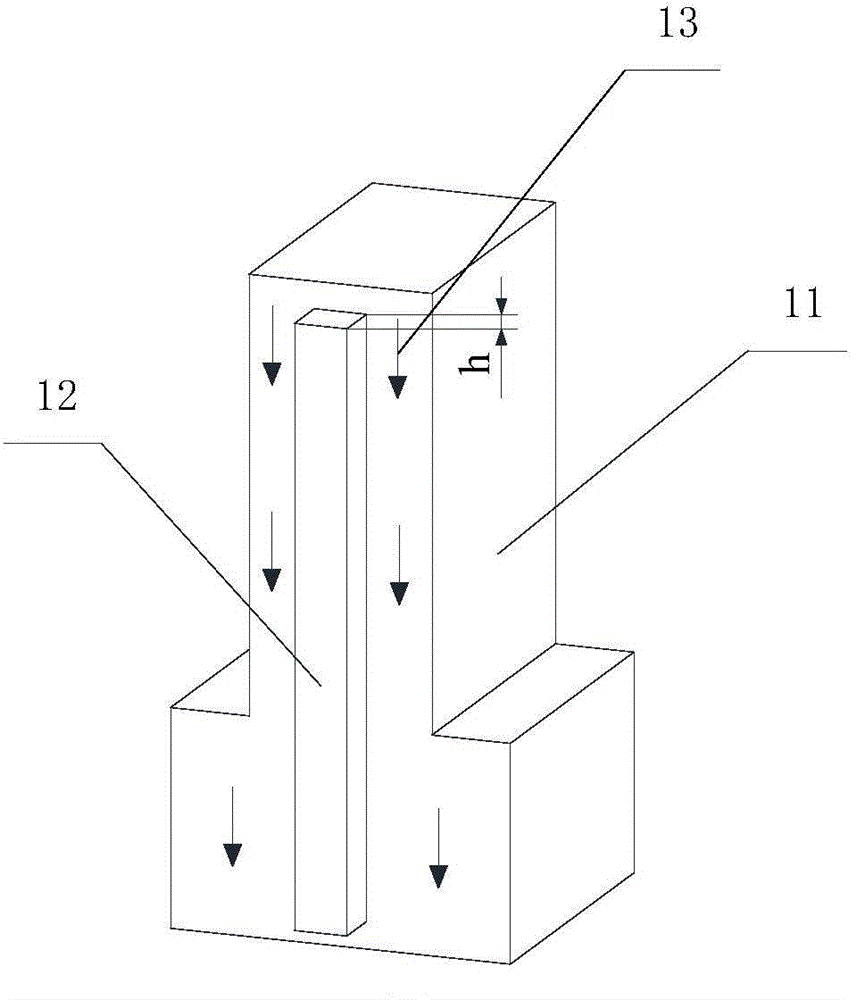

[0051] Figure 4 Schematic diagram of the adjusted size of the ventilation channel steel in one embodiment of the motor radial ventilation cooling structure provided by the present invention, Figure 5 for Figure 4 The schematic diagram of the structure of the ventilation channel steel in the radial ventilation cooling structure of the motor shown. Such as Figure 4 , Figure 5 As shown, on the basis of Embodiment 1 or Embodiment 2, the radial ventilation and cooling structure of the motor in this embodiment provides that by adjusting the size of the ventilation channel steel 12 (including the height h in the axial direction of the motor and / or The width w) in the circumferential direction of the motor makes the impedance R of the plurality of ventilation grooves 13 gradually increase along the direction from both ends of the motor to the middle of the motor.

[0052] Specifically, the ventilation channel steel 12 in this embodiment is still an overall in-line strip-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com