Converter valve tower

A technology for diverter valves and valve towers, applied in the field of diverter valve towers, which can solve the problems of a large number of supporting valve towers and high steel beam design requirements, and achieve lower strength design requirements, reduce the number of valve towers, and design Effect of Difficulty Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

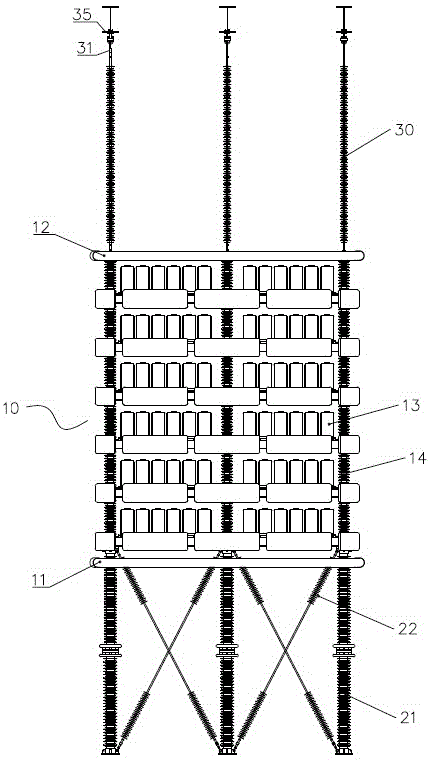

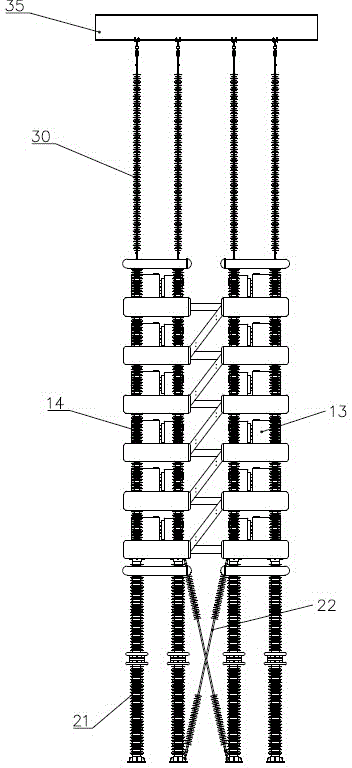

[0018] An embodiment of the valve tower of the diverter valve in the present invention is as follows Figure 1-Figure 3 As shown, the valve tower of the converter valve is a new type of semi-suspended and semi-supported valve tower, which is based on the structure of the supported valve tower, including the valve tower body 10 and the support insulator 21 for supporting the valve tower body 10, The structure of the valve tower body 10 and the structure of the supporting insulator 21 are the same as those of the supporting valve tower in the prior art, and will not be repeated here.

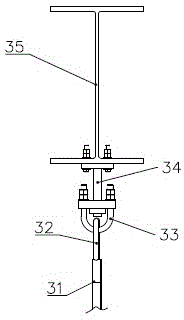

[0019] The top steel beam of the valve tower body 10 is connected with a suspension insulator 30 through the flexible connection mechanism of the valve tower body. The insulator 30 and the valve tower body 10 can relatively swing in the horizontal direction. The top of the suspension insulator 30 is provided with a suspension beam connecting structure for connecting with the suspension beam 35 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com