Laser processing apparatus and laser processing method

A technology of laser processing and laser beams, which is applied in the direction of fine working devices, laser welding equipment, stone processing equipment, etc., can solve problems affecting processing accuracy and achieve the effects of energy loss suppression and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

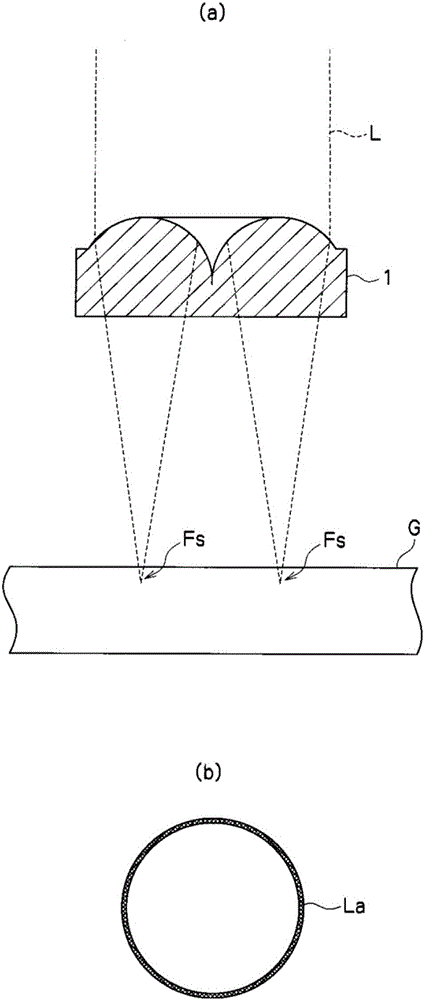

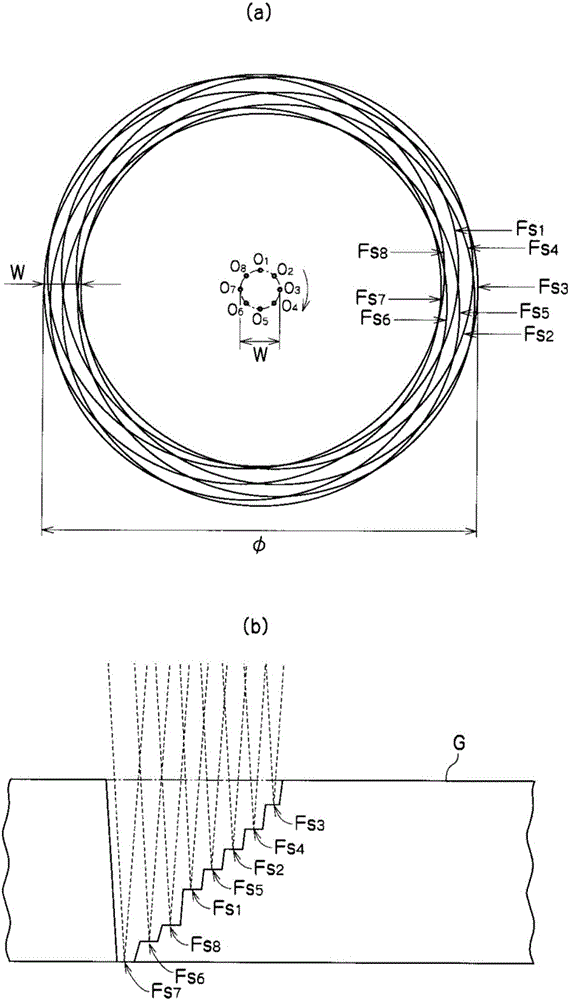

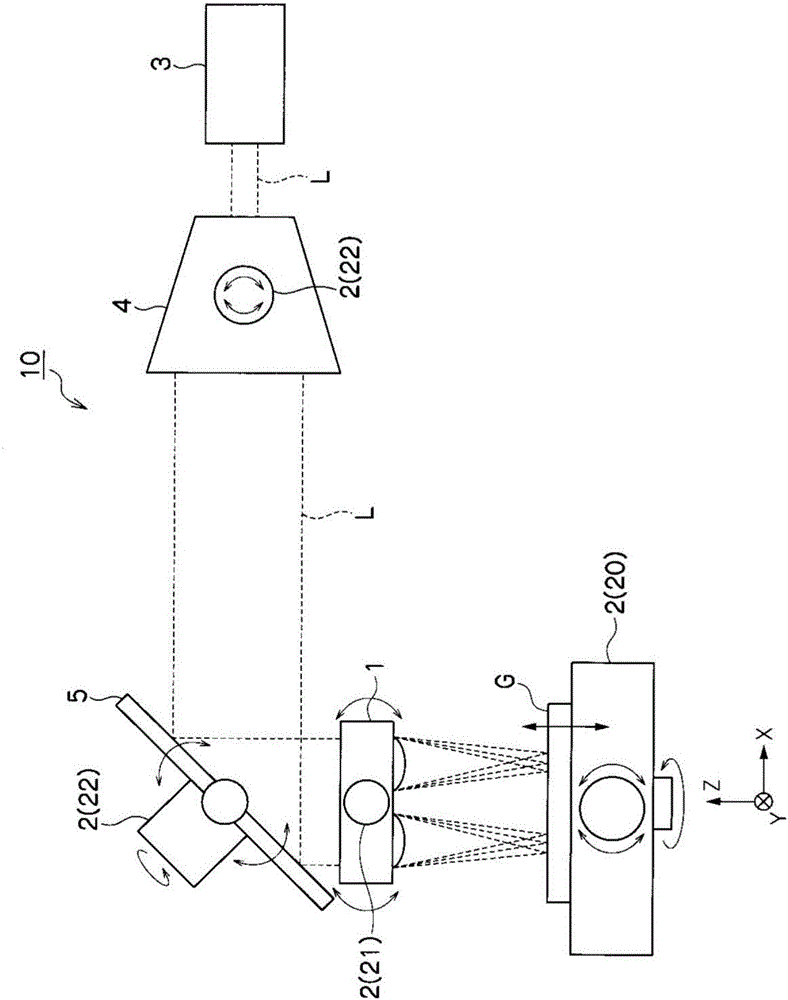

[0023] Hereinafter, a laser processing device and a laser processing method according to an embodiment of the present invention will be described with reference to the drawings. figure 1 It is an explanatory diagram showing a form example of a laser lens used in an embodiment of the present invention ( figure 1 (a) is a figure which shows the cross-sectional shape of a condensing lens and the condensing state of a laser beam, figure 1 (b) is a plan view of the beam shape of the laser beam condensed into a ring shape). The condensing lens 1 condenses the laser beam L into a ring shape and irradiates its condensing position Fs within a substantially G thickness range. The condensing lens 1 basically sets the cylindrical lens as an annular shape, and by injecting the laser beam L with a circular cross-section shaped into a predetermined beam diameter into the effective aperture, the following can be obtained: figure 1 The ring-shaped light-condensing state La shown in (b).

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com