Pond food field area contamination drainage system with back flushing function

A sewage system and recoil system technology, applied in the field of fishery production, can solve the problems of reducing the production and benefits of pond culture, consuming dissolved oxygen in water areas, reducing effective water bodies, etc., to achieve increased production and benefits, large effective water bodies, and short sewage discharge time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

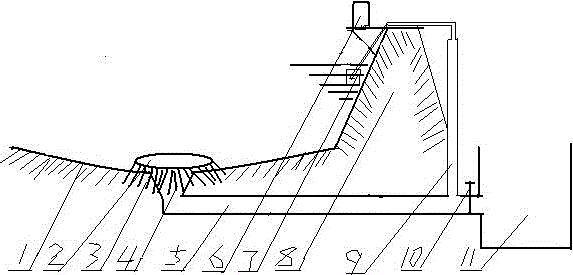

[0008] The present invention is illustrated in conjunction with the accompanying drawings, a sewage discharge system for a pond food field area capable of recoil, characterized in that the sewage discharge system is composed of a bottom sewage discharge system and a recoil system, and the bottom sewage discharge system includes: the bottom presents as a "concave "" shaped canteen area pool bottom (1), "concave"-shaped sewage outlet (4) in the central area, sewage isolation cover (2) above the sewage outlet (4), and sewage isolation teeth around the sewage isolation cover (2) (3), the sewage pipe (5) buried at the bottom of the pool connected to the sewage outlet (4), the sewage valve (10), and the sewage collection ditch (11); the recoil system includes: a recoil pump (7), Recoil pipe (9); the bottom (1) of the food field area is located near the ridge (8) of the pond, and the feeder (6) is set at the ridge (8), and the feeding port surface of the feeder (6) For the food field...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com