Granular material gas-solid separation collector

A technology for gas-solid separation and granular materials, which is applied in the direction of devices where the axial direction of the swirl can be reversed, swirl devices, etc., can solve the problems of low utilization rate of equipment, waste of resources, difficult maintenance, etc., and achieve improved separation and collection The effect of high efficiency, reduced land occupation, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

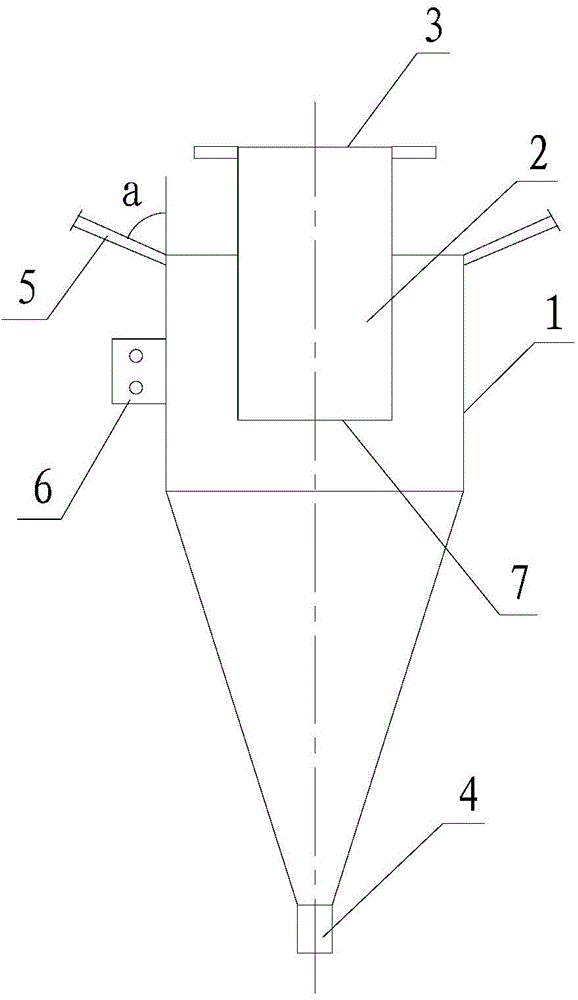

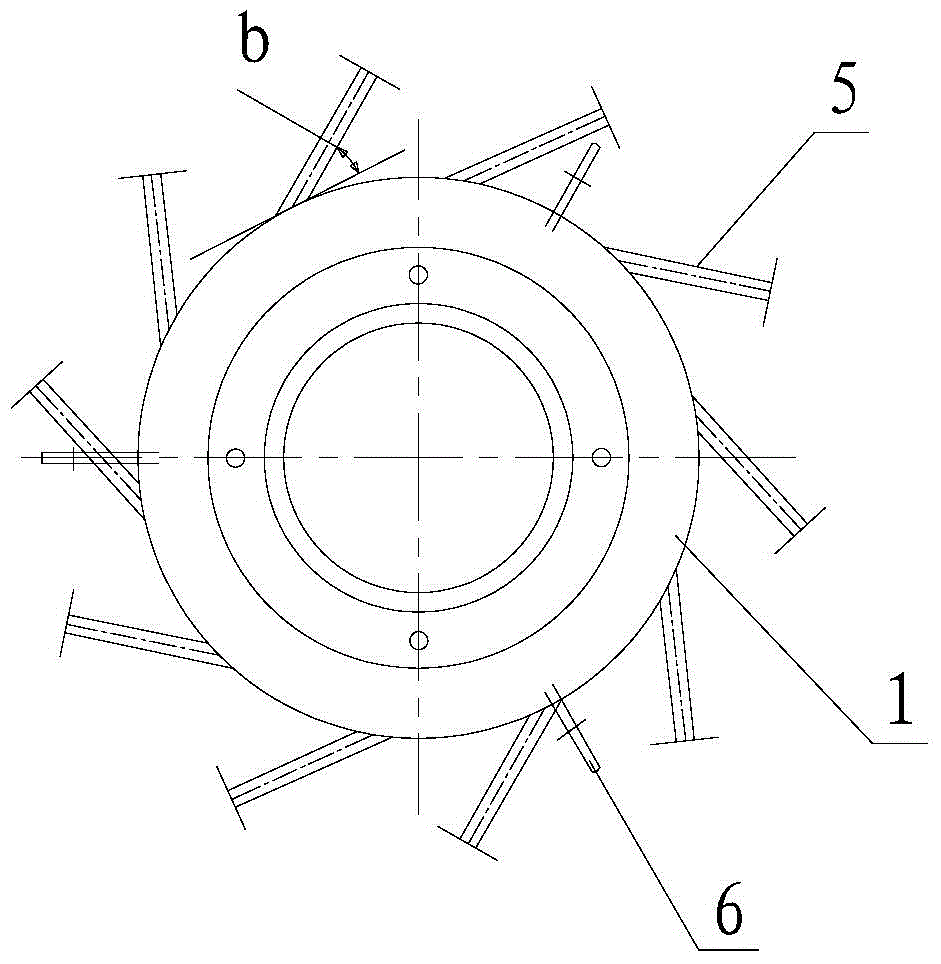

[0015] like figure 1 , figure 2 As shown, the present invention includes a cylindrical shell 1 and an air guide pipe 2 located inside the shell 1. The top of the shell 1 is provided with an air outlet 3, and the bottom is provided with a discharge port 4. The air guide pipe 2 and the air outlet 3 are connected, and the air guide pipe 3 is provided with a filter screen 7, and the filter screen 7 is used to block materials and prevent them from being discharged from the air outlet 3. At least two feed pipes 5 are arranged on the top side of the housing 1 , and the axes of the feed pipes 5 intersect with the housing 1 in both horizontal and vertical directions to form a certain angle. The angle between the feed pipe 5 and the vertical direction of the shell 1 refers to the intersection point and the vertical plane where the center of the shell 1 is located as the refer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com