Combined track type automatic inspection robot

An inspection robot and automatic inspection technology, applied in the field of electric power, can solve problems such as limited data range, no inspection robot, and inconvenient inspection work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]It is easy to understand that, according to the technical solution of the present invention, those skilled in the art can imagine various implementations of the combined track-type automatic inspection robot of the present invention without changing the essence of the present invention. Therefore, the following specific embodiments and drawings are only exemplary descriptions of the technical solution of the present invention, and should not be regarded as the entirety of the present invention or as a limitation or limitation on the technical solution of the present invention.

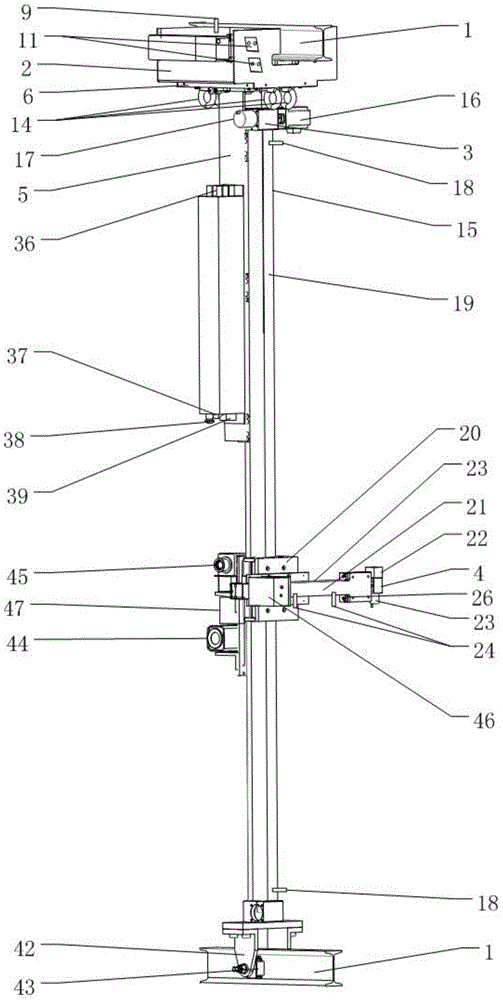

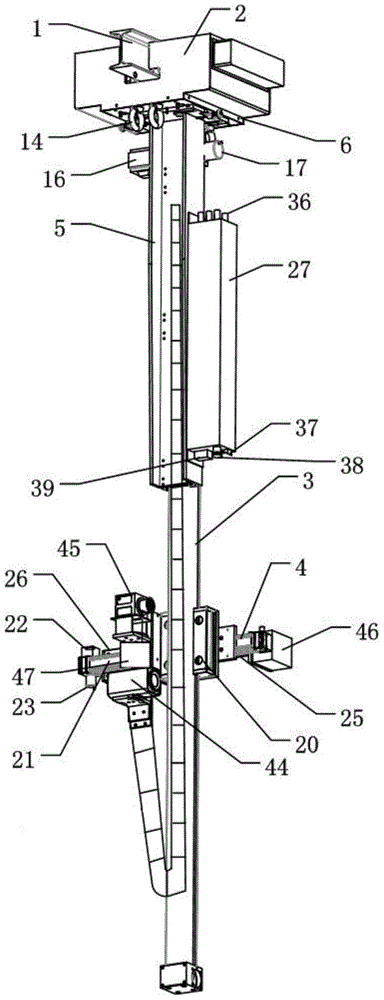

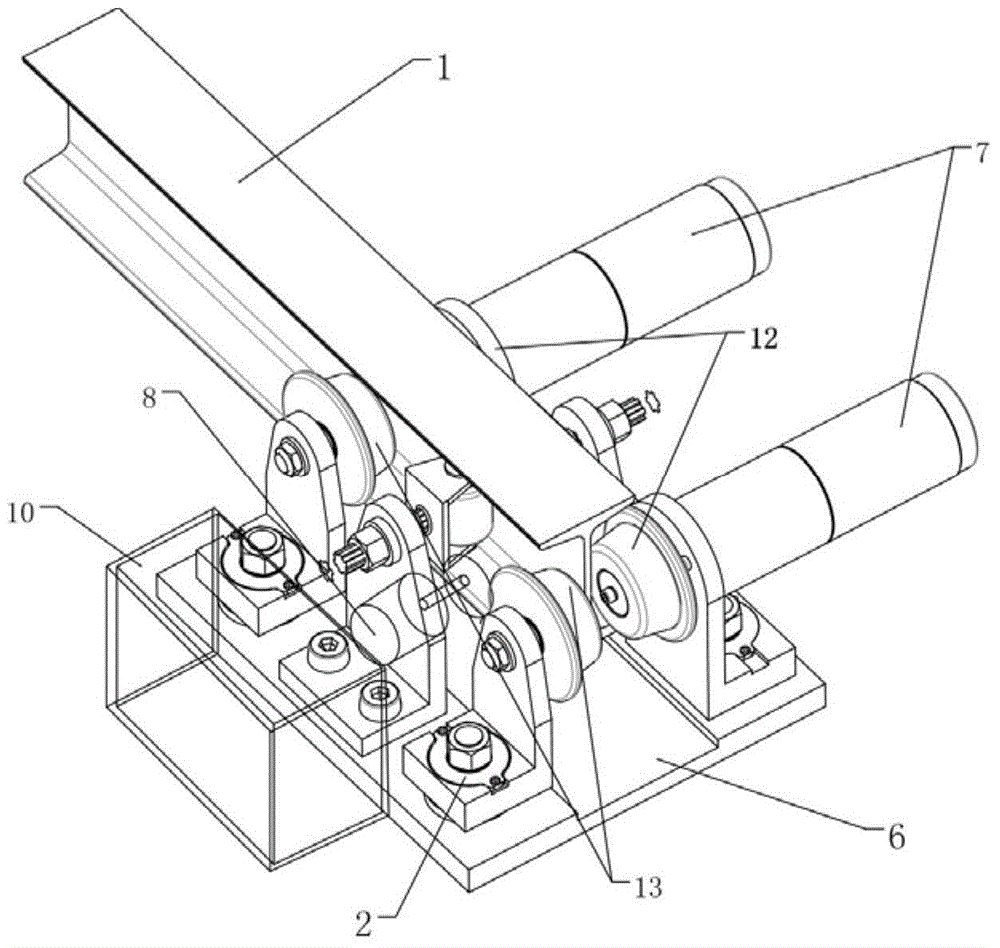

[0028] to combine figure 1 , in this embodiment, include a robot running track 1, a robot body running on the running track, a detection sensor carried by the robot body, and a PC terminal 48. The running track 1 includes two parts, an upper track and a lower track. The robot body is vertically installed between the upper and lower tracks, and is used to realize that the robot body runs in the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com