PET/PCM color hammer tone laminated steel plate

A technology of laminated steel plate and hammer pattern, which is applied in the field of PET/PCM color hammer pattern laminated steel plate, can solve the problems of delayed cracking of the coating and achieve the effects of bright colors, delayed cracking and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

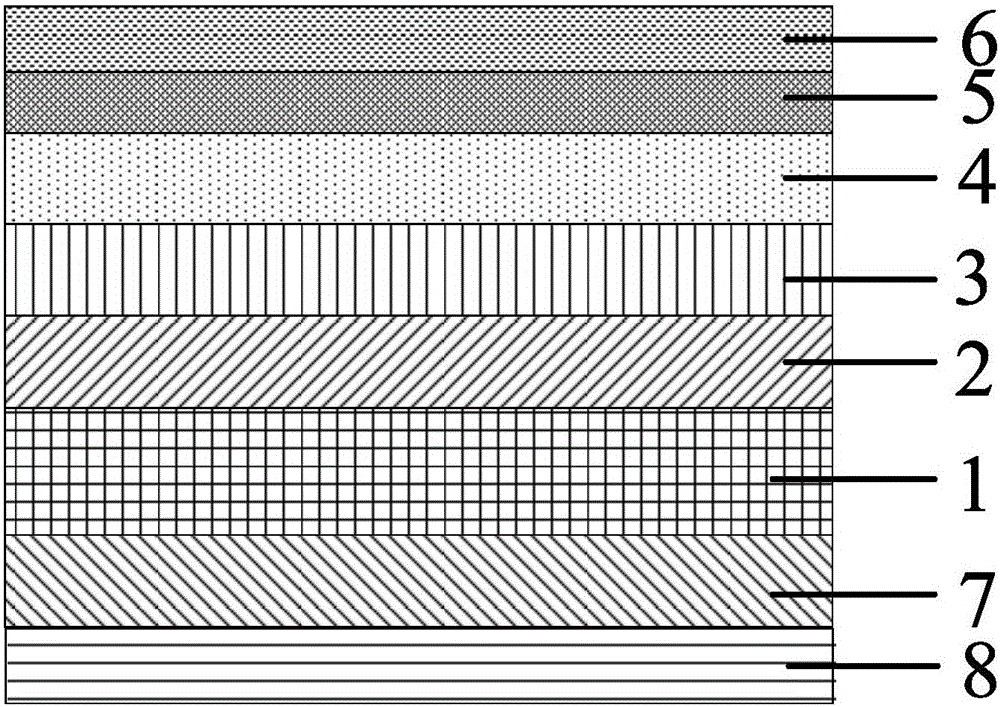

[0016] Such as figure 1 As shown, the PET / PCM color hammer-grain laminated steel plate, the base material 1 is a steel plate, the front side of the base material 1 is passivated to form a front passivation layer 2, and the front passivation layer 2 is coated with a polyester primer to form a polyester Primer layer 3, polyester primer layer 3 is coated with hammer-grain polyester varnish to form hammer-grain polyester varnish layer 4, hammer-grain polyester varnish layer 4 is coated with hammer-grain polyester topcoat to form hammer-grain polyester surface The paint layer 5 is covered and pasted with a protective film layer 6 on the hammer grain polyester finish paint layer 5 . A back passivation layer 7 is formed on the back passivation of the substrate 1 , and a back paint layer 8 is coated on the back passivation layer 7 .

[0017] The steel plate is used as the substrate, and the adhesion between the paint and the steel plate is enhanced by passivation and coating of polye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com