Needle type sucker

A suction cup and pin-type technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of high physical consumption, increased labor costs, and large manpower investment, and achieve low manufacturing costs, reasonable structural design, and high automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the present invention will be further described to facilitate the understanding of technical personnel.

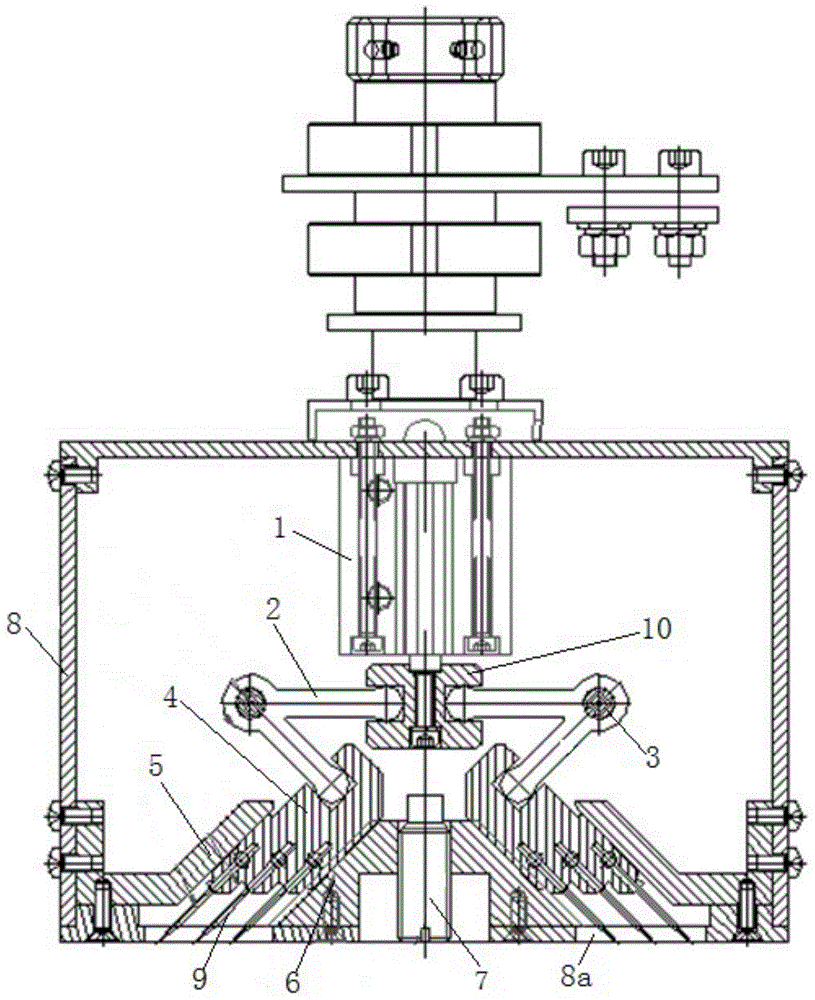

[0012] Such as figure 1 As shown, a needle sucker includes a cylinder 1, a lever 2, a shaft 3, a slider 4, an upper fixed slider 5, a lower fixed slider 6, an adjustment rod 7, a frame 8, a steel needle 9 and an adapter block 10. The upper end of the cylinder 1 is fixed on the frame 8 by screws, the adapter block 10 is fixed on the piston rod of the cylinder 1, the driving rod 2 has a V-shaped structure, and the number of the driving rods 2 is two root, two driving rods 2 are symmetrically distributed on the left and right sides below the adapter block 10, the shaft 3 passes through the corners of the driving rod 2 correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com