Niobium-containing R4 mooring cable steel and heat treatment technology and production method thereof

A production method and mooring chain technology, applied in the direction of improving process efficiency, can solve problems such as increasing the probability of welding cracks, deteriorating steel weldability, increasing production costs, etc., to improve overall performance uniformity, enhance competitiveness, The effect of improving hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

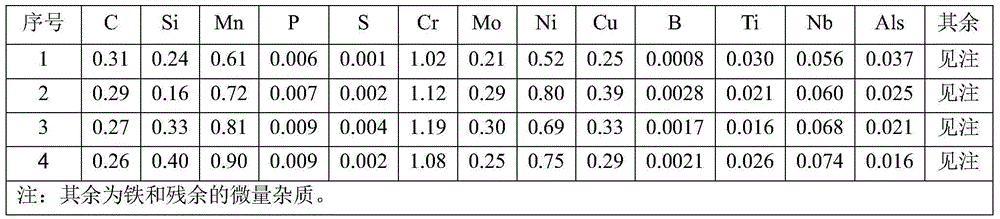

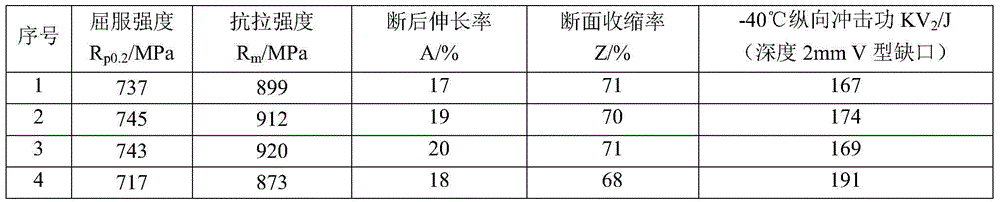

[0032] In a preferred embodiment, there is provided a steel for mooring chain containing niobium and its heat treatment process, the mass percentage (wt%) of the steel for mooring chain containing niobium R4 is: C: 0.26~0.31, Si: 0.15~0.40, Mn: 0.60~0.90, P: ≤0.010, S: ≤0.005, Cr: 1.00~1.20, Mo: 0.20~0.30, Ni: 0.50~0.80, Nb: 0.055~0.075, Ti: 0.010~0.030, Cu: 0.25-0.40, B: 0.0008-0.0030, Als: 0.015-0.050, and the rest are iron and residual trace impurities. The composition design of the steel of the present invention is based on the principle of alloying with multiple elements and a small amount:

[0033] (1) Carbon: C is the main strengthening element and hardenability improving element, but if C is too high, the plasticity and toughness of the steel will decrease and the weldability wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact absorption energy | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com