Torsion rubber core

A rubber core and torsion technology, which is applied to springs, springs/shock absorbers, and mechanical equipment made of plastic materials, can solve problems such as difficult buffering, fracture of the upper and lower covers of the ball pins, and affecting the service life of the torsion rubber core. Achieve the effect of stable improvement, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further explain the technical solution of the present invention, it will be described in detail below in conjunction with the accompanying drawings.

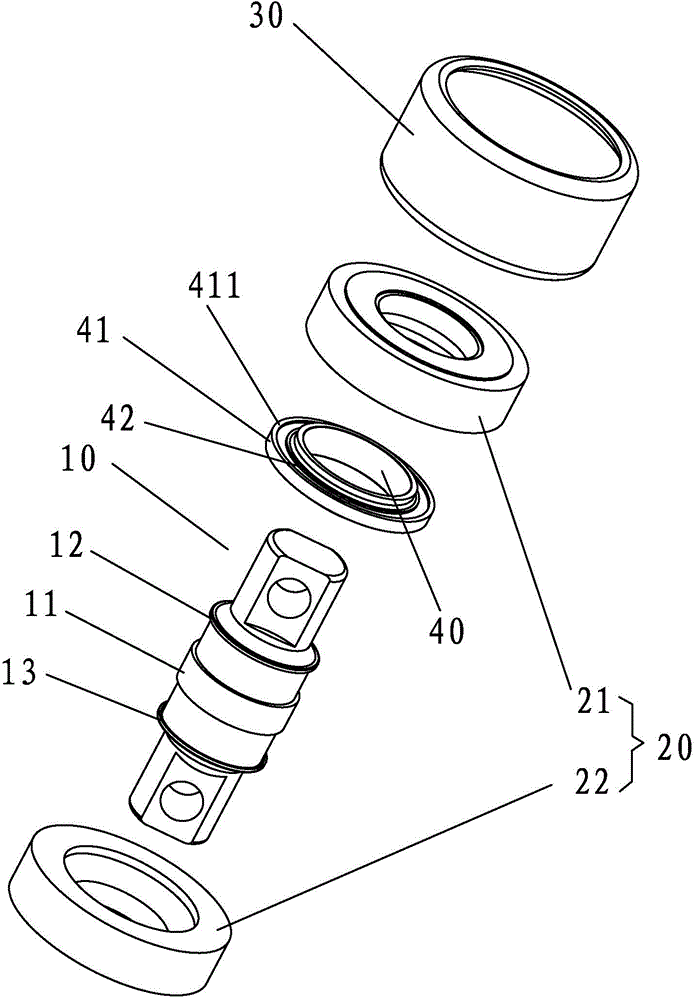

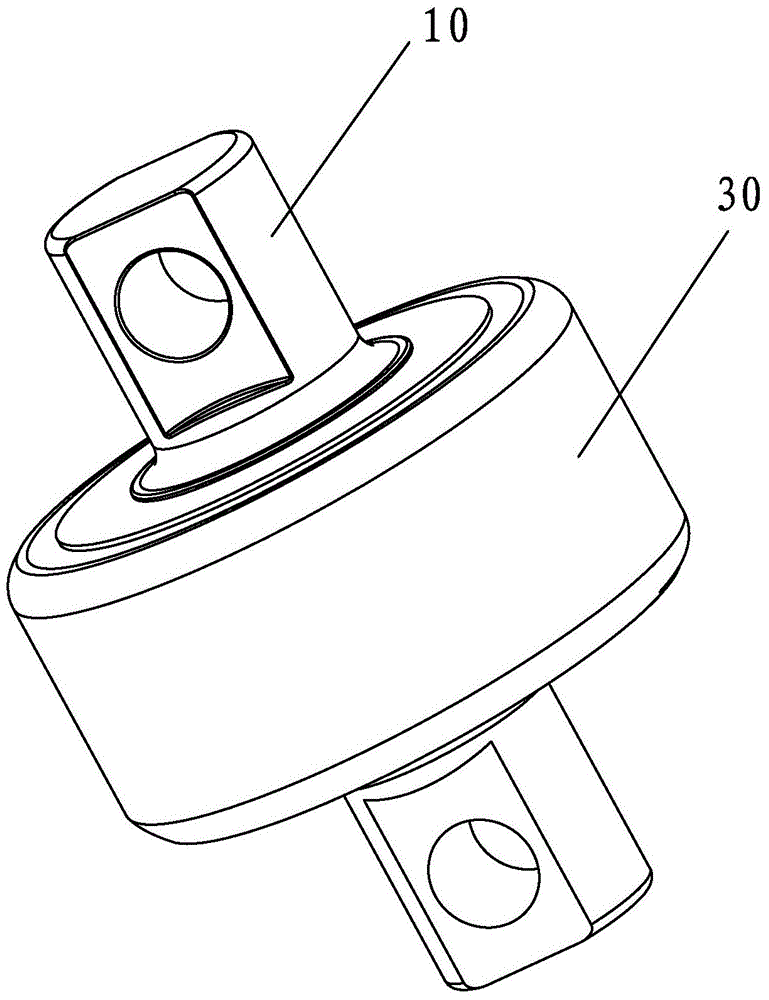

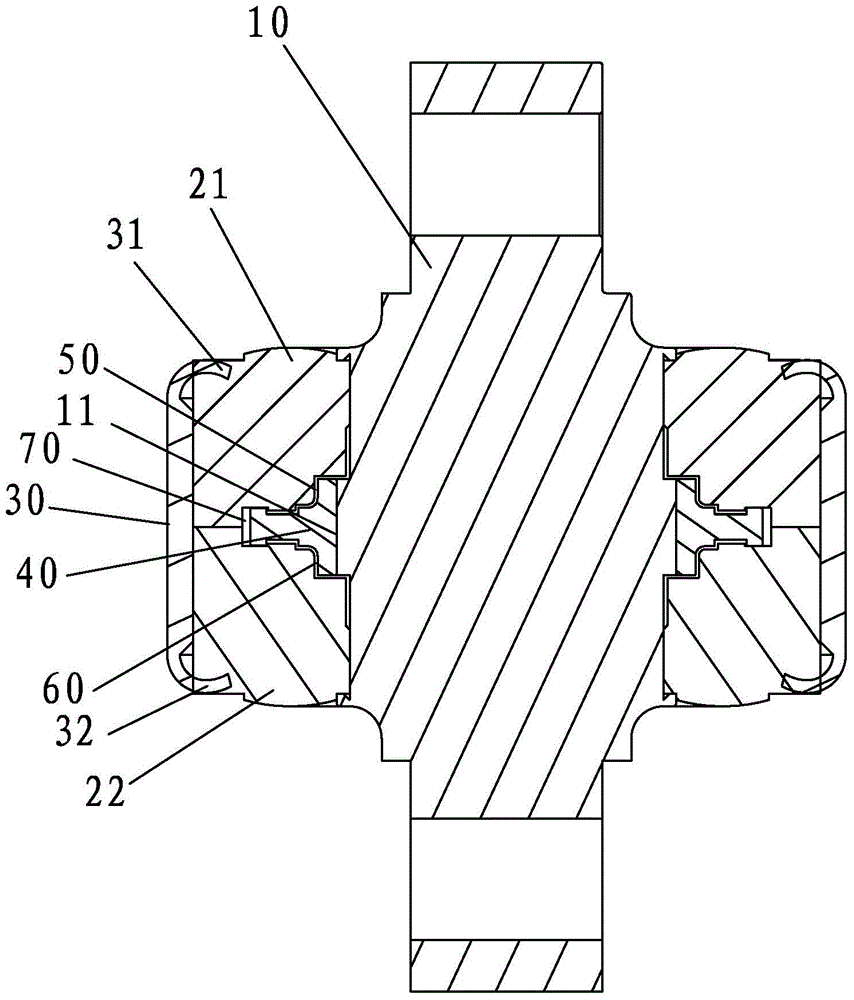

[0041] refer to Figure 1 to Figure 5 , a torsion rubber core, comprising a torsion rubber mandrel 10, a rubber pad 20 sleeved on the torsion rubber mandrel 10 and a fastening sleeve 30 sleeved outside the rubber pad 20, the rubber pad 20 is a rubber pad, tight The fixed sleeve 30 adopts a steel sleeve, and the surface of the fastening sleeve 30 is provided with an electroless chrome plating layer to enhance the corrosion resistance and wear resistance of the fastening sleeve 30 .

[0042] The present invention also includes an elastic piece 40 sleeved on the torsion rubber mandrel 10, a support portion 41 is formed on the elastic piece 40, the elastic piece 40 is processed into a corresponding shape by a seamless tube, and the rubber pad 20 includes a The first rubber pad 21 and the second rubber pad 22 on b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com